The Ultimate Guide on Biscuit Machine Price in 2024

Introduction

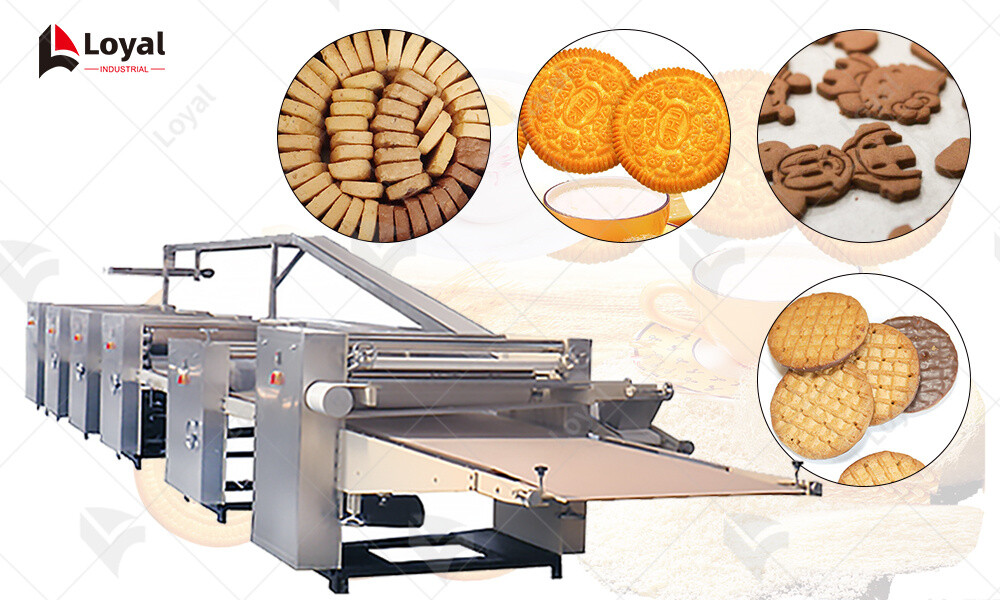

Understanding biscuit machine price dynamics is crucial for businesses looking to invest in biscuit production in 2024. The cost of a biscuit machine is influenced by various factors, including material quality, technological advancements, brand reputation, and production capacity. As the food industry evolves, staying informed about these pricing elements can help companies make well-informed decisions and achieve a better return on investment.

In this comprehensive guide, we will delve into the key factors affecting biscuit machine prices, explore the price range of different types of biscuit machines, and provide insights on conducting a cost-benefit analysis. By the end of this guide, you will have a thorough understanding of biscuit machine pricing and be equipped to choose the best machine that fits your production needs and budget.

Factors Affecting Biscuit Machine Price

When considering the investment in a biscuit machine, understanding the various factors that influence biscuit machine price is crucial. In 2024, several key elements will determine the cost of these machines, impacting budget planning and purchasing decisions for manufacturers.

1. Material and Build Quality

The quality of materials used in constructing a biscuit machine significantly affects its price. Machines made from high-grade stainless steel and other durable materials tend to be more expensive due to their longevity, resistance to corrosion, and overall reliability. Investing in robust materials ensures the machine can withstand the rigors of continuous production.

2. Technological Advancements and Features

Advanced features and technologies incorporated into biscuit machines play a pivotal role in their pricing. Machines equipped with the latest automation technologies, such as programmable logic controllers (PLCs), touch-screen interfaces, and precision sensors, typically command higher prices. These features enhance production efficiency, accuracy, and ease of operation, justifying the additional cost.

3. Brand Reputation and Market Presence

The reputation and market presence of the manufacturer can also impact biscuit machine price. Renowned brands known for their quality and reliability may charge a premium for their machines. Established manufacturers often offer better customer support, comprehensive warranties, and a proven track record, which can add value to the investment.

4. Production Capacity and Efficiency

The production capacity of a biscuit machine, measured in biscuits per minute or hour, is a critical factor in its pricing. Higher capacity machines designed for large-scale production facilities will generally be more expensive than those intended for small to medium-sized operations. Efficiency-enhancing features, such as faster baking times and automated dough handling, also contribute to higher costs.

5. Customization and Flexibility Options

Machines that offer greater flexibility and customization options are usually priced higher. This includes the ability to produce a variety of biscuit shapes, sizes, and textures with interchangeable molds and adjustable settings. Customizable machines allow manufacturers to diversify their product offerings, catering to different market demands and consumer preferences.

Price Range of Different Types of Biscuit Machines

When considering the investment in biscuit production, understanding the price range of different types of biscuit machines is crucial. Here's a detailed look at the price ranges for various biscuit machines in 2024, which will help in making informed decisions.

1. Entry-Level Machines

Entry-level biscuit machines are ideal for small-scale production or startups entering the biscuit industry. These machines typically offer basic functionalities and are designed for lower production capacities.

- Features: Simple controls, manual or semi-automatic operation, limited production capacity, basic customization options.

- Price Range: $5,000 - $20,000

2. Mid-Range Machines

Mid-range biscuit machines are suitable for medium-sized businesses looking to increase their production capabilities without investing in high-end equipment. These machines offer a balance between cost and functionality.

- Features: Automated or semi-automated operation, higher production capacity, moderate customization options, improved durability.

- Price Range: $20,000 - $75,000

3. High-End Machines

High-end biscuit machines are designed for large-scale production facilities that require advanced features and high output capacities. These machines incorporate the latest technologies to ensure efficiency and consistency.

- Features: Fully automated systems, high production capacity, extensive customization options, advanced control systems, and high precision.

- Price Range: $75,000 - $200,000

4. Specialty Machines for Niche Markets

Specialty biscuit machines cater to specific niche markets and are designed to produce unique types of biscuits that standard machines may not handle efficiently. These could include gluten-free biscuits, organic biscuits, or artisanal products.

- Features: Customizable settings for specialized production, unique design features, specific ingredient handling capabilities.

- Price Range: $50,000 - $150,000

In conclusion, the price range of biscuit machines varies significantly based on their features, production capacity, and intended use. Understanding these price brackets helps manufacturers and investors choose the right equipment to match their production needs and budget. By evaluating the specific requirements and long-term benefits, businesses can make well-informed decisions on their investment in biscuit production machinery.

Hidden Costs and Additional Expenses

When considering the biscuit machine price, it’s crucial to account for hidden costs and additional expenses that may arise post-purchase. Understanding these costs will help ensure a more accurate budget and prevent unexpected financial strains. Here are key areas to consider:

1. Maintenance and Servicing Costs

Regular maintenance is essential to keep biscuit machines operating efficiently. This includes routine inspections, cleaning, lubrication, and replacement of worn parts. Maintenance costs can vary depending on the machine's complexity and usage frequency. Additionally, some advanced machines may require specialized technicians, which can further increase servicing expenses.

2. Energy Consumption and Operating Costs

Biscuit machines can consume significant amounts of energy, especially those operating at high capacities. It's important to consider the electricity requirements and efficiency of the machine. Energy-efficient models may have a higher initial biscuit machine price but can offer long-term savings on utility bills. Monitoring energy consumption and optimizing production schedules can help manage these ongoing costs.

3. Cost of Spare Parts and Accessories

Over time, parts of the biscuit machine may wear out and need replacement. The availability and cost of these spare parts should be factored into the overall budget. It's advisable to choose machines from reputable manufacturers who provide easy access to replacement parts. Additionally, consider any necessary accessories or add-ons that enhance the machine's functionality and production capacity.

4. Training and Labor Costs

Operating advanced biscuit machines may require specialized training for staff. Training programs, whether provided by the manufacturer or third-party providers, can incur additional costs. Furthermore, consider the labor costs associated with hiring skilled operators or technicians to manage and maintain the equipment. Investing in proper training can improve efficiency and reduce the risk of operational errors.

Market Trends Influencing Biscuit Machine Prices

In 2024, various market trends are significantly impacting biscuit machine prices. Understanding these trends is crucial for businesses looking to invest in biscuit production machinery. Here are some key factors:

1. Technological Innovations

Technological advancements in the food machinery industry are continuously evolving. Modern biscuit machines now incorporate features like automation, precision engineering, and IoT integration, which enhance efficiency and production capabilities. However, these advancements come at a cost. As a result, the price of biscuit machines has increased to reflect the added value of these cutting-edge technologies.

2. Global Supply Chain Dynamics

The global supply chain has experienced considerable fluctuations due to various factors, including geopolitical tensions, trade policies, and the aftermath of the COVID-19 pandemic. These disruptions have led to increased costs for raw materials and components essential for manufacturing biscuit machines. Consequently, manufacturers are adjusting their prices to accommodate these higher production costs.

3. Consumer Demand for Specialized Biscuits

Consumer preferences are shifting towards more specialized and health-conscious biscuit options, such as gluten-free, organic, and low-sugar varieties. To meet these demands, biscuit machine manufacturers are developing specialized equipment capable of producing a diverse range of biscuit types. The increased demand for versatile and high-performance machines has contributed to a rise in biscuit machine prices.

4. Sustainability and Eco-Friendly Practices

There is a growing emphasis on sustainability within the food industry. Biscuit machine manufacturers are now focusing on developing eco-friendly machines that consume less energy, reduce waste, and utilize sustainable materials. While these green technologies are beneficial for the environment and can lead to long-term cost savings, they often come with higher initial investment costs, thereby influencing the overall price of biscuit machines.

5. Customization and Flexibility

The need for customization and flexibility in biscuit production is more pronounced than ever. Manufacturers require machines that can easily adapt to different recipes, shapes, and sizes of biscuits. The ability to customize machines to meet specific production needs adds to the complexity and cost of these machines. As a result, the prices of highly adaptable and customizable biscuit machines are on the rise.

Financing Options for Biscuit Machine Purchase

When considering the acquisition of a biscuit machine, exploring various financing options is crucial to ensure a smooth and cost-effective transaction. Here are some financing avenues to explore for purchasing a biscuit machine:

1. Equipment Loans

Equipment loans are a common financing option for businesses looking to invest in machinery like biscuit machines. These loans are specifically tailored for purchasing equipment and typically offer competitive interest rates and flexible repayment terms. Businesses can use the biscuit machine itself as collateral, making it easier to secure financing.

2. Leasing

Leasing a biscuit machine is another viable option for businesses seeking flexibility and cost-effectiveness. With a lease, the business pays a monthly fee to use the machine without having to purchase it outright. Leasing arrangements often include maintenance and servicing, alleviating the burden on the business owner. Additionally, leasing allows businesses to upgrade to newer models more easily as technology advances.

3. Equipment Financing Programs

Many manufacturers and distributors of biscuit machines offer in-house financing programs to facilitate the purchase process for their customers. These programs may include low or zero-interest financing options, deferred payment plans, or other incentives to encourage purchases. By taking advantage of manufacturer financing, businesses can streamline the buying process and potentially save on upfront costs.

4. Small Business Administration (SBA) Loans

For small businesses in the United States, SBA loans can be a valuable resource for financing equipment purchases, including biscuit machines. SBA loans are partially guaranteed by the government, which reduces the risk for lenders and allows them to offer favorable terms to borrowers. These loans can be used to finance a variety of business expenses, including equipment purchases, with longer repayment periods and lower interest rates than conventional loans.

5. Equipment Leasing Companies

Specialized equipment leasing companies offer financing solutions tailored specifically for machinery and equipment purchases. These companies understand the unique needs of businesses in the manufacturing industry and can provide customized financing packages to suit their requirements. Working with an equipment leasing company can streamline the financing process and ensure businesses get the best possible terms for their biscuit machine purchase.

6. Vendor Financing

Some biscuit machine manufacturers or distributors may offer vendor financing arrangements to their customers. This type of financing allows businesses to purchase equipment directly from the manufacturer or distributor and pay for it over time through installment payments. Vendor financing often comes with competitive interest rates and flexible terms, making it an attractive option for businesses looking to acquire a biscuit machine.

Tips for Getting the Best Value

When considering the purchase of a biscuit machine, obtaining the best value for your investment is paramount. Here are some expert tips to help you make an informed decision and get the most out of your biscuit machine purchase:

1. Evaluate Your Production Needs

Before diving into the market, thoroughly assess your biscuit production requirements. Consider factors such as desired production capacity, types of biscuits to be produced, and future growth projections. This evaluation will guide you in selecting a machine that aligns with your specific needs, ensuring that you invest in the right equipment from the outset.

2. Research Different Manufacturers and Models

Take the time to research and compare biscuit machine models from various manufacturers. Look beyond just the price tag and delve into factors such as build quality, reliability, and customer reviews. Opting for a reputable manufacturer known for producing high-quality machines can offer greater long-term value, even if the initial price may be higher.

3. Consider Total Cost of Ownership

When assessing biscuit machine prices, don't focus solely on the upfront cost. Consider the total cost of ownership, which includes factors such as maintenance, energy consumption, and spare parts. A slightly higher-priced machine with lower operating costs and minimal maintenance requirements may offer better value in the long run.

4. Negotiate for Discounts and Incentives

Don't hesitate to negotiate with manufacturers or suppliers for discounts, especially when purchasing multiple machines or committing to a long-term contract. Many manufacturers offer promotional discounts, financing options, or bundled packages that can help you save on overall costs. Be prepared to leverage your purchasing power to secure the best deal possible.

5. Explore Financing Options

If the upfront cost of a biscuit machine is a concern, explore financing options such as equipment leasing or installment plans. Financing allows you to spread out the cost over time, making it more manageable for your budget. Be sure to compare different financing offers and choose the option that best fits your financial situation and objectives.

6. Seek Recommendations from Industry Peers

Reach out to other biscuit manufacturers or industry professionals for recommendations and insights into biscuit machine purchases. Their firsthand experiences and recommendations can provide valuable guidance in selecting the right machine and negotiating favorable terms. Networking within the industry can also uncover hidden gems or lesser-known manufacturers offering competitive prices without compromising on quality.

7. Prioritize After-Sales Support and Service

A biscuit machine's value extends beyond its initial purchase price to include after-sales support and service. Choose a manufacturer or supplier that offers comprehensive after-sales support, including training, technical assistance, and readily available spare parts. Investing in a machine with reliable support ensures minimal downtime and maximum productivity, ultimately enhancing the machine's overall value.

8. Take Advantage of Technology and Innovation

Consider investing in biscuit machines equipped with advanced technologies and innovations that offer greater efficiency, productivity, and quality. While these machines may come with a higher price tag, their superior performance and capabilities can deliver significant value by streamlining production processes and improving product consistency.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/