The Ultimate Bread Crumbs Making Machine Guide to 2024

Introduction to Bread Crumbs Making Machines

Bread crumbs making machines are essential equipment in the food processing industry, designed to produce consistent and high-quality bread crumbs used in various culinary applications. These machines streamline the production process, ensuring efficiency and uniformity in the final product.

In recent years, advancements in technology have significantly enhanced the capabilities of bread crumbs making machines. Modern machines offer automated processes, improved energy efficiency, and enhanced control systems, making them a valuable asset for both small-scale and large-scale food manufacturers.

Benefits of Using Bread Crumbs Making Machines

Increased Efficiency and Productivity: Utilizing a bread crumbs making machine drastically improves production efficiency. These machines automate the bread crumb production process, reducing the time and labor required compared to manual methods. This leads to higher productivity and the ability to meet increased demand.

Consistency and Quality Control: One of the significant advantages of using bread crumbs making machines is the ability to produce uniform and high-quality bread crumbs consistently. The machines are designed to maintain precise control over the crumb size and texture, ensuring that each batch meets the required standards.

Cost-Effective Production: Although the initial investment in a bread crumbs making machine may be substantial, the long-term benefits include reduced labor costs and minimized waste. Automation reduces human error and optimizes the use of raw materials, leading to cost savings over time.

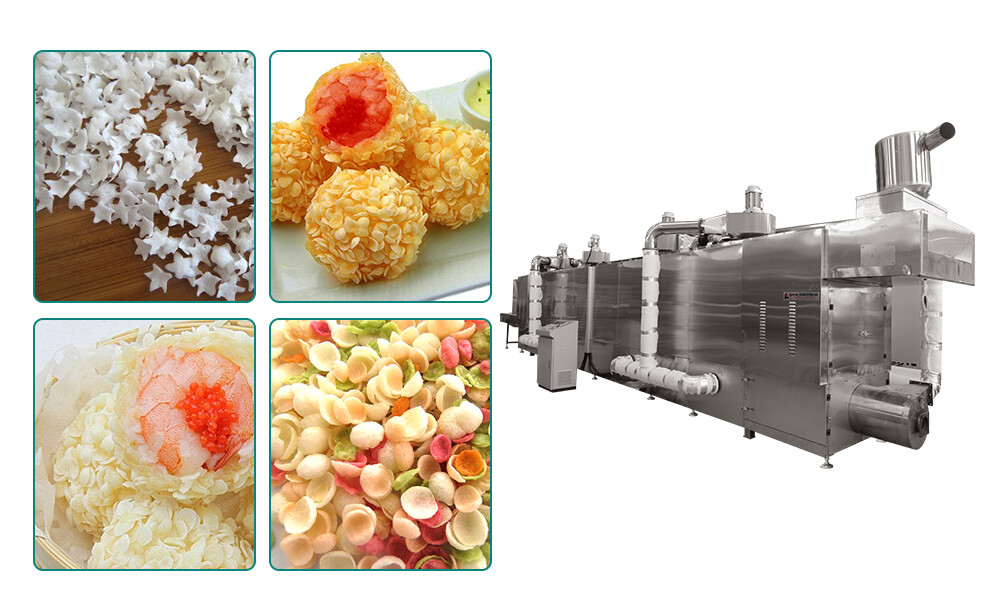

Versatility in Production: Modern bread crumbs making machines offer versatility in production, allowing manufacturers to produce different types of bread crumbs, such as fine, coarse, and Japanese-style panko crumbs. This flexibility enables food processors to cater to a broader range of culinary requirements and market demands.

Key Features of Modern Bread Crumbs Making Machines

Feature | Description |

| Automation and Control Systems | Advanced bread crumbs making machines come with automated control systems that regulate the entire production process, from mixing to packaging. |

| Energy Efficiency | Modern machines are designed to be energy-efficient, reducing power consumption and operational costs. |

| Adjustable Settings | These machines offer adjustable settings for crumb size and texture, allowing customization based on specific requirements. |

| High-Quality Materials | Constructed from durable and food-grade materials, ensuring long-term use and compliance with food safety standards. |

| Easy Maintenance and Cleaning | Designed for easy disassembly and cleaning, reducing downtime and ensuring hygiene standards are maintained. |

| Safety Features | Equipped with safety mechanisms to prevent accidents and ensure safe operation during the production process. |

| Versatile Production Capabilities | Capable of producing various types of bread crumbs, including fine, coarse, and panko, to meet diverse market needs. |

| Efficient Cooling Systems | Integrated cooling systems to ensure the bread crumbs are cooled quickly and evenly, maintaining quality and texture. |

| User-Friendly Interface | Intuitive control panels and interfaces make it easy for operators to manage and monitor the production process. |

| Scalability | Suitable for both small-scale and large-scale production, with options to upgrade or expand capacity as needed. |

How to Choose the Right Bread Crumbs Making Machine

Selecting the right bread crumbs making machine is critical for ensuring efficient and high-quality production. The first factor to consider is production capacity. Assess your business needs and choose a machine that can handle your desired output without compromising quality. Smaller operations might benefit from compact, less complex machines, while large-scale producers will need robust, high-capacity models.

Next, consider the types of bread crumbs you aim to produce. Different machines are designed to create various textures, from fine to coarse crumbs. Ensure the machine you select can produce the specific type of crumbs your products require. Versatile machines that offer multiple settings for different crumb types can provide added value and flexibility.

Another important aspect is automation and control systems. Modern bread crumbs making machines come equipped with advanced automation features that streamline the production process, reduce labor costs, and minimize human error. Look for machines with user-friendly interfaces, programmable settings, and reliable safety features.

Finally, evaluate the machine's build quality and maintenance requirements. Durable materials and a robust design will ensure longevity and consistent performance. Additionally, consider the ease of cleaning and maintaining the machine, as regular upkeep is essential for hygiene and operational efficiency. Opt for models that offer easy access to parts and straightforward maintenance procedures.

Types of Bread Crumbs Produced by Different Machines

Type of Bread Crumbs | Description | Ideal Machine Features |

| Fine Bread Crumbs | Small, uniform particles, often used for coatings and fillings. | High-speed grinders, fine sieves. |

| Coarse Bread Crumbs | Larger, irregular particles, suitable for crunchy coatings. | Adjustable grinding settings, coarse sieves. |

| Panko Bread Crumbs | Light, airy flakes, traditionally used in Japanese cuisine. | Specialized rollers, precise cutting mechanisms. |

| Colored Bread Crumbs | Crumbs infused with colors for aesthetic purposes. | Machines with coloring agents and uniform mixing capabilities. |

| Seasoned Bread Crumbs | Crumbs mixed with herbs and spices for added flavor. | Integrated seasoning dispensers and mixers. |

Detailed Overview of the Bread Crumbs Production Process

The bread crumbs production process begins with the selection of the appropriate bread. Typically, day-old bread is preferred due to its reduced moisture content, which ensures a consistent crumb texture. The chosen bread is then sliced into manageable pieces, either manually or using automated slicing equipment.

Next, the bread slices undergo baking and drying. This step involves placing the bread in an industrial oven where it is baked at controlled temperatures to achieve the desired level of dryness. Proper drying is crucial as it prevents mold growth and extends the shelf life of the bread crumbs.

Following the drying process, the bread is ground into crumbs. Depending on the type of crumbs needed, the bread is fed into a grinder or crusher, which breaks it down into the desired particle size. Fine crumbs require additional grinding and sifting to ensure uniformity, while coarse crumbs might only need a single pass through the grinding equipment.

The final step is sifting and sorting. The ground bread crumbs are passed through a series of sieves to separate particles by size. This ensures that the end product meets the specific requirements for different applications. In some cases, additional processing such as seasoning or coloring is done at this stage. The finished bread crumbs are then packaged and prepared for distribution, ensuring they are stored in a moisture-free environment to maintain quality.

Essential Components of a Bread Crumbs Making Machine

When considering a bread crumbs making machine, it's crucial to understand its essential components. Below is a detailed breakdown:

Component | Description |

| Feeding System | Feeding system ensures a consistent flow of raw materials into the machine, typically through a hopper. |

| Grinding Mechanism | The grinding mechanism processes bread slices into crumbs of desired texture, often through rotating blades or rollers. |

| Sifting Unit | A sifting unit separates the ground crumbs from larger debris, ensuring uniformity in the final product. |

| Drying Chamber | The drying chamber removes moisture from the crumbs, enhancing their shelf life and texture. |

| Cooling System | A cooling system cools down the dried crumbs before packaging, preventing moisture buildup. |

| Packaging Station | The packaging station efficiently packs the bread crumbs into bags or containers, ready for distribution. |

| Control Panel | The control panel allows operators to monitor and adjust various parameters of the machine, such as speed and temperature. |

Understanding these components helps in selecting the right bread crumbs making machine for your production needs.

Automation and Control Systems in Bread Crumbs Machines

In the landscape of bread crumbs making machines, automation and control systems have undergone significant advancements, transforming the way these machines operate. Here's a deeper dive into the role of automation and control systems in enhancing the efficiency, consistency, and safety of bread crumbs production:

Automated Feeding: Gone are the days of manual labor-intensive feeding processes. Modern bread crumbs making machines now incorporate automated feeding systems. These systems ensure a continuous and precise supply of raw materials into the machine, eliminating the need for constant human intervention. This not only reduces labor costs but also minimizes the risk of errors in ingredient measurement, resulting in a more consistent end product.

Precision Grinding: The heart of any bread crumbs making machine lies in its grinding mechanism. Advanced control systems integrated into these machines regulate the grinding process with unmatched precision. By controlling factors such as blade speed, pressure, and feed rate, these systems ensure uniformity in crumb size and texture. This level of precision guarantees that each batch of bread crumbs meets the desired specifications, enhancing product quality and customer satisfaction.

Temperature Control: Temperature plays a critical role in the drying and cooling processes of bread crumbs production. To maintain the quality and shelf life of the final product, modern machines are equipped with sophisticated temperature control systems. These systems continuously monitor and adjust the temperature within the drying and cooling chambers, optimizing conditions for moisture removal and preservation. By preventing overheating or under-drying, they ensure that the bread crumbs retain their freshness, flavor, and crispiness.

Real-time Monitoring: In today's fast-paced production environments, real-time monitoring is indispensable for maintaining optimal machine performance. Bread crumbs making machines now come equipped with integrated sensors and monitoring devices that provide operators with instant access to crucial data. From monitoring blade wear and motor efficiency to tracking production rates and energy consumption, these systems offer valuable insights into machine performance. This real-time data empowers operators to make immediate adjustments, troubleshoot issues proactively, and minimize downtime, ultimately enhancing overall productivity and profitability.

Automation and control systems have revolutionized the bread crumbs making industry by streamlining production processes, improving product quality, and reducing operational costs. As technology continues to evolve, these systems will remain essential tools for manufacturers seeking to stay competitive in the dynamic food processing landscape.

Maintenance and Troubleshooting of Bread Crumbs Making Machines

Proper maintenance is essential for maximizing the lifespan and efficiency of bread crumbs making machines. Below is a detailed maintenance and troubleshooting guide:

Maintenance Task | Frequency | Description |

| Cleaning Blades | Weekly | Remove residue buildup on grinding blades to prevent contamination. |

| Lubricating Moving Parts | Monthly | Apply lubricant to moving parts to reduce friction and wear. |

| Inspecting Electrical Connections | Quarterly | Check electrical connections for loose wires or corrosion. |

| Calibration Check | Biannually | Calibrate control systems to ensure accurate operation. |

| Belt Replacement | Annually | Replace worn-out belts to prevent breakdowns. |

Troubleshooting common issues:

Uneven Grinding: Check for blade alignment and adjust as needed.

Excessive Noise: Inspect bearings and replace if worn.

Overheating: Ensure proper ventilation and check cooling systems for blockages.

Regular maintenance and timely troubleshooting are crucial for keeping bread crumbs making machines running smoothly and efficiently.

Innovations and Technological Advances in Bread Crumbs Machines

Advanced Grinding Mechanisms:Modern bread crumbs making machines are equipped with advanced grinding mechanisms that ensure a consistent texture and quality of bread crumbs. These machines employ innovative techniques to finely grind bread into uniform crumbs, enhancing the overall efficiency of the production process.

Automation and Control Systems:One notable innovation in bread crumbs machines is the integration of advanced automation and control systems. These systems allow for precise monitoring and adjustment of various parameters such as grinding speed, temperature, and moisture levels, resulting in optimized production efficiency and product consistency.

Multi-Functional Capabilities:Recent advancements in bread crumbs making machines have led to the development of multi-functional models that can process a variety of bread types and sizes. These versatile machines offer increased flexibility and productivity, enabling producers to meet diverse market demands with ease.

Energy-Efficient Designs:In response to growing environmental concerns, manufacturers have introduced energy-efficient designs in bread crumbs making machines. These machines are engineered to minimize energy consumption while maximizing output, contributing to sustainability efforts within the food processing industry.

Case Studies of Successful Bread Crumbs Production Facilities

Golden Crumbs Bakery (USA):Golden Crumbs Bakery, located in the United States, has established itself as a leading producer of high-quality bread crumbs using state-of-the-art machines. By investing in cutting-edge technology and adhering to stringent quality control measures, the bakery has achieved remarkable success in the competitive bread crumbs market.

Crispy Delights Factory (Germany):Crispy Delights Factory in Germany is renowned for its innovative approach to bread crumbs production. With a focus on utilizing the latest advancements in machinery and processing techniques, the factory has earned a reputation for delivering superior products that consistently exceed customer expectations.

Sunrise Crumbs Co. (Japan):Sunrise Crumbs Co. in Japan has embraced technological innovation to streamline its bread crumbs production process. By leveraging automated machinery and precision engineering, the company has achieved unparalleled efficiency and product consistency, positioning itself as a leader in the global bread crumbs industry.

Conclusion:

Innovations in bread crumbs making machines continue to revolutionize the food processing industry, driving efficiency, quality, and sustainability. Through case studies of successful production facilities, we witness firsthand the transformative impact of these advancements on bread crumbs manufacturing in 2024.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com