The Ultimate Biscuit Making Machine for Small Business Guide to 2024

Introduction to Biscuit Making Machines for Small Businesses

In 2024, small businesses in the food industry are increasingly turning to advanced biscuit making machines to enhance productivity and ensure consistent quality. These machines are essential for small-scale operations, offering efficiency, precision, and the ability to meet growing consumer demands. By integrating a cookie making machine into their production line, small business owners can streamline their processes, reduce labor costs, and maintain a competitive edge in the market.

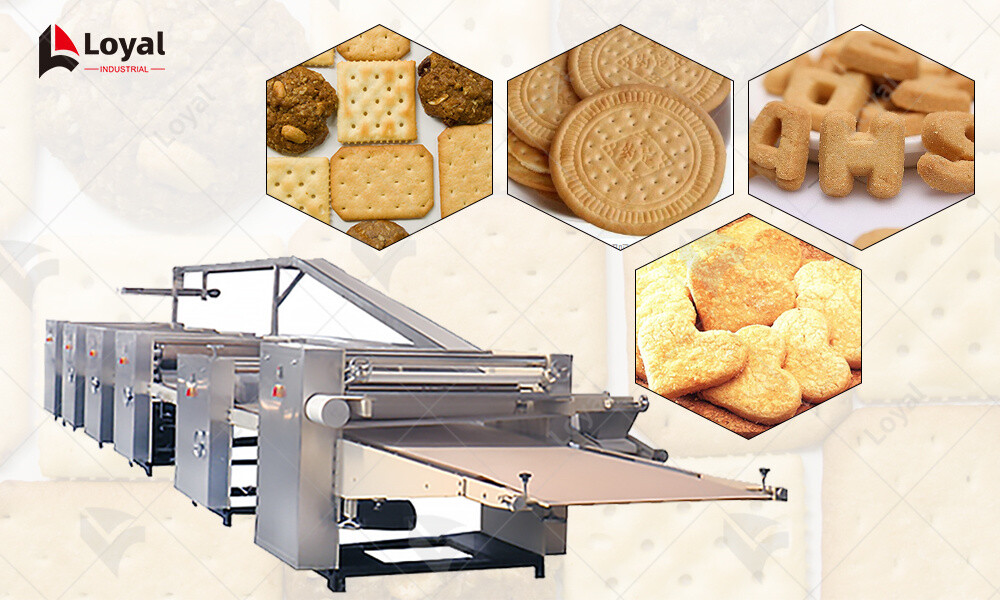

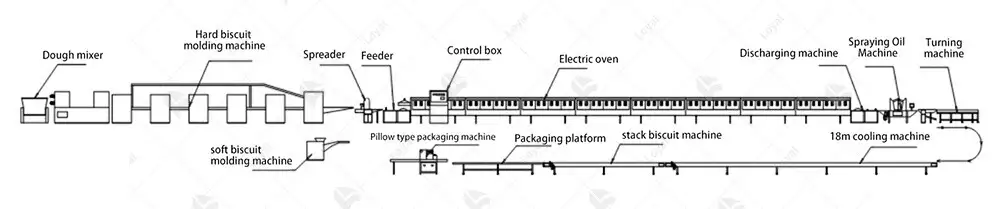

A biscuit making machine is designed to automate the various stages of biscuit production, from mixing and forming to baking and packaging. These machines are not only time-saving but also ensure that each biscuit is produced to the exact specifications, ensuring uniformity and high quality. For small businesses, investing in a cookie making machine can lead to significant improvements in production capacity and product consistency, which are crucial for building a loyal customer base.

The range of biscuit making machines available today caters to different production needs and budgets. Whether you're a startup bakery or an established small business looking to upgrade your equipment, understanding the key features and benefits of these machines can help you make an informed decision. This guide will provide insights into the most important aspects of biscuit making machines, helping you choose the best option for your business in 2024.

Key Features of Biscuit Making Machines

| Feature | Description |

| Automated Mixing | Ensures consistent dough quality by automating the mixing process. This feature reduces the need for manual intervention, leading to uniform and high-quality biscuit dough. |

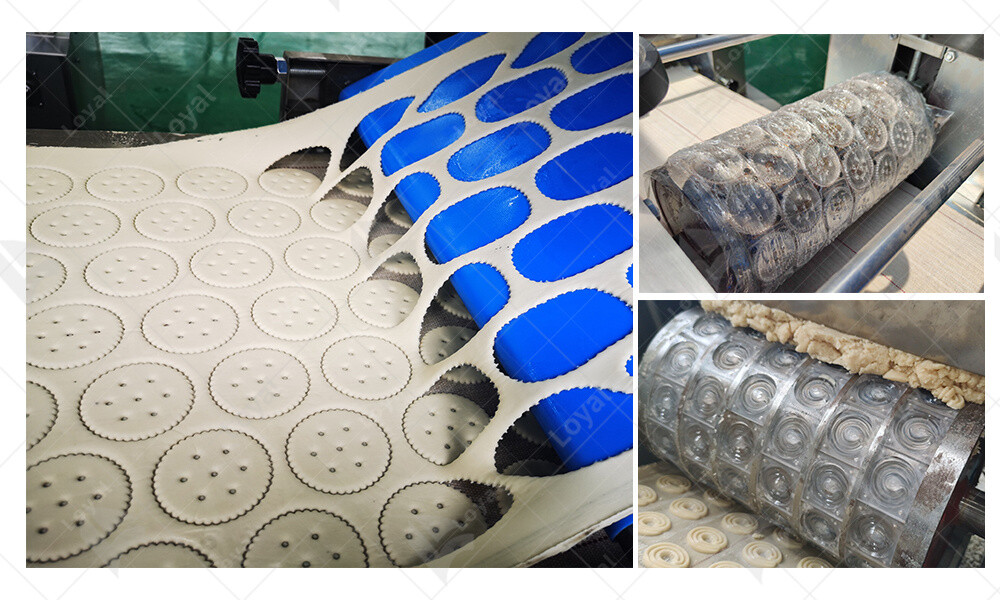

| Precision Forming | Utilizes advanced technology to shape biscuits precisely and consistently. This ensures each biscuit meets exact specifications, crucial for maintaining product standards. |

| High-Volume Output | Designed to handle large batches, these machines can produce a significant number of biscuits in a short time, making them ideal for small businesses aiming for growth. |

| Easy-to-Use Interface | Features user-friendly controls and interfaces, allowing operators to easily manage and adjust production parameters. This reduces training time and operational errors. |

| Energy Efficiency | Incorporates energy-saving technologies to reduce power consumption, helping businesses lower their operational costs while maintaining high production levels. |

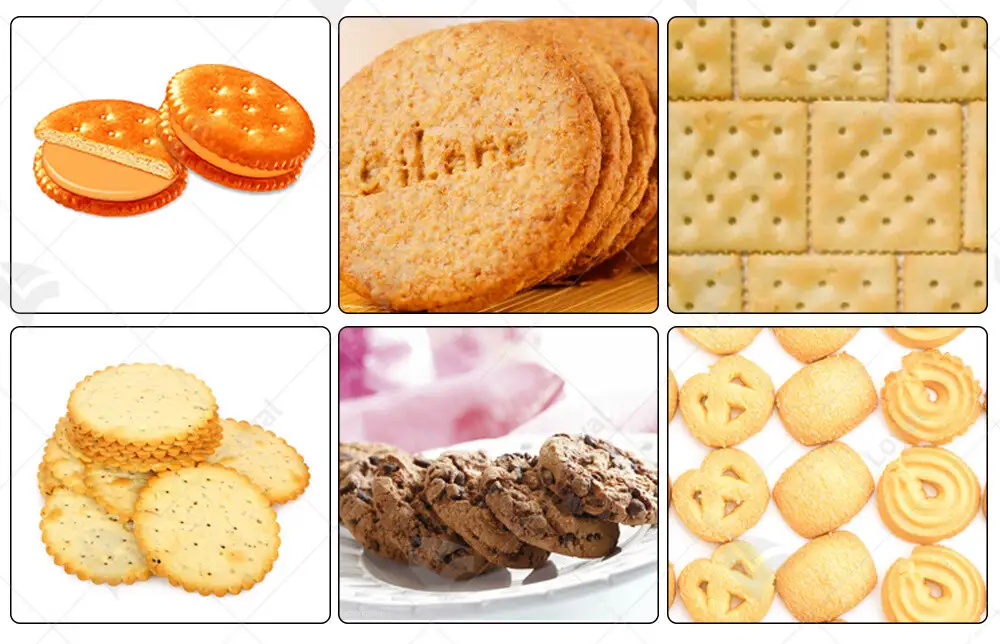

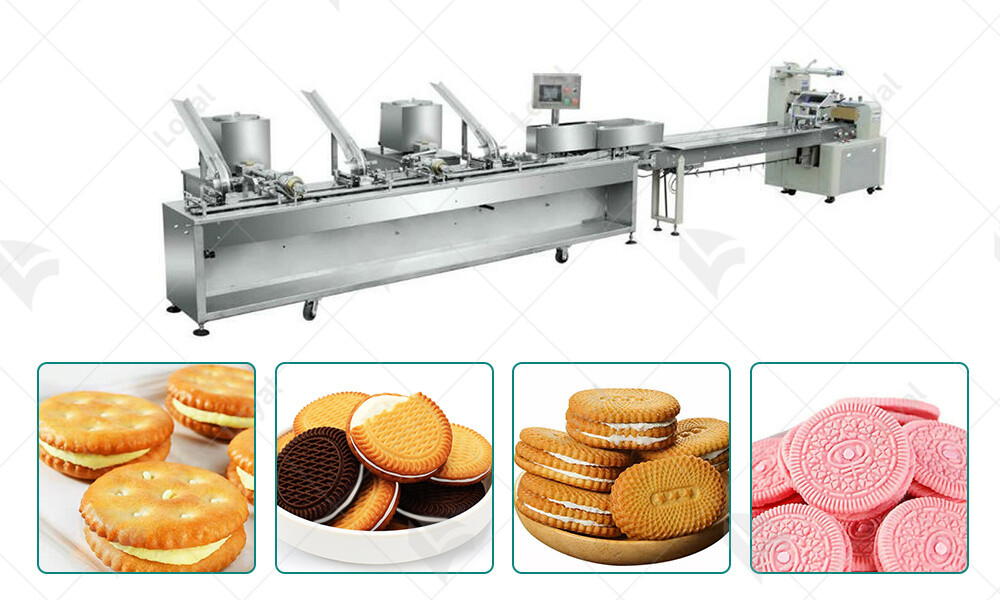

| Versatility | Capable of producing various types of biscuits and cookies, including different shapes, sizes, and flavors. This flexibility allows businesses to expand their product range. |

| Durable Construction | Built with high-quality materials to withstand continuous use, ensuring longevity and reliable performance over time. |

Types of Biscuit Making Machines for Small Businesses

When considering biscuit making machines for your small business, it's essential to understand the variety of options available. Below is a breakdown of the most common types:

| Type of Machine | Description |

| Dough Mixer | Utilizes rotating blades to thoroughly mix ingredients, ensuring consistency in dough texture. |

| Dough Sheeter | Flattens dough to a consistent thickness, crucial for uniformity in biscuit size and shape. |

| Biscuit Forming Machine | Shapes the dough into desired biscuit forms, streamlining the production process. |

| Baking Oven | The heart of the operation, baking the formed biscuits to perfection through controlled heat and airflow. |

| Cooling Conveyor | Allows biscuits to cool down post-baking, preparing them for packaging or further processing. |

Each of these machines plays a vital role in the biscuit-making process, contributing to the overall efficiency and quality of the final product. When selecting machines for your small business, consider factors such as production capacity, space availability, and budget constraints to make an informed decision.

Choosing the Right Biscuit Making Machine for Your Business

Assessing Production Needs: Before investing in biscuit making machines, evaluate your production requirements. Consider factors such as anticipated demand, desired output volume, and future scalability. This assessment will guide you in selecting machines that can meet your business's current and future needs.

Quality and Durability: Opt for machines constructed from high-quality materials that can withstand the rigors of continuous operation. While initial costs may be higher for premium machines, their durability can lead to long-term cost savings by reducing maintenance and replacement expenses.

Ease of Maintenance: Look for machines that are easy to clean and maintain. Regular maintenance is essential to ensure optimal performance and prolong the lifespan of your equipment. Choose models with accessible components and user-friendly interfaces to simplify maintenance tasks.

Vendor Reputation and Support: Research reputable vendors known for their quality products and excellent customer support. Prioritize vendors that offer comprehensive warranties, training programs, and timely technical assistance. Establishing a reliable partnership with your equipment supplier is crucial for ongoing support and troubleshooting.

Installation and Setup of Biscuit Making Machines

Preparation of Workspace: Before installing biscuit making machines, prepare the designated workspace to accommodate the equipment. Ensure adequate ventilation, electrical connections, and flooring capable of supporting heavy machinery. Clear any obstructions and create a layout that promotes efficient workflow and safety.

Machine Assembly: Follow the manufacturer's instructions for assembling each machine, paying close attention to safety precautions and proper alignment. Verify that all components are securely fastened and calibrated according to specifications. Conduct thorough testing to confirm the functionality of each machine before proceeding.

Integration into Production Line: Integrate the biscuit making machines into your existing production line, ensuring seamless operation and compatibility with other equipment. Coordinate with your team to establish workflow protocols, including loading raw materials, monitoring production progress, and inspecting finished products.

Training and Familiarization: Provide comprehensive training to your staff on operating and maintaining the biscuit making machines. Emphasize safety procedures, equipment functionalities, and troubleshooting techniques to empower your team to handle day-to-day operations effectively. Encourage open communication and continuous learning to optimize machine performance and productivity.

By following these guidelines for installation and setup, you can maximize the efficiency and reliability of your biscuit making machines, setting the stage for success in your small business venture.

Maintenance Tips for Biscuit Making Machines

Biscuit making machines are indispensable assets for small businesses delving into the confectionery industry. To ensure the seamless functioning of these intricate devices, proper maintenance is paramount. Here are some expert tips to keep your biscuit making machine operating at peak efficiency:

One of the foundational steps in maintaining a biscuit making machine is adhering to a strict cleaning regimen. Crumbs, dough residue, and grease buildup can hinder performance and compromise the quality of your biscuits. Utilize mild detergents and non-abrasive materials to clean the equipment thoroughly after each production cycle. Pay special attention to nooks and crannies where food particles tend to accumulate.

Proper lubrication is the lifeblood of any machinery, and biscuit making machines are no exception. Regularly inspect moving parts such as conveyor belts, rollers, and gears for signs of friction or wear. Apply food-grade lubricants and greases as recommended by the manufacturer to ensure smooth operation and prevent premature breakdowns. Over-lubrication should be avoided to prevent contamination of the biscuit dough.

Maintaining precision in biscuit making is crucial for consistent product quality. Periodically calibrate and align the various components of your biscuit making machine to ensure accurate cutting, shaping, and baking processes. Misalignment can lead to irregular biscuit sizes, uneven baking, and ultimately, customer dissatisfaction. Invest in precision instruments and consult the machine's manual for detailed calibration procedures.

Preventive maintenance is the cornerstone of maximizing the lifespan of your biscuit making machine. Establish a comprehensive schedule for routine inspections and servicing tasks such as belt tension adjustments, motor checks, and electrical system evaluations. Addressing minor issues promptly can prevent them from escalating into major malfunctions that disrupt production schedules and incur costly repairs.

By incorporating these maintenance tips into your operational framework, you can prolong the longevity of your biscuit making machine and ensure consistent output quality. Remember, a well-maintained machine is not only a testament to your commitment to excellence but also a cornerstone of sustainable business growth in the competitive confectionery market.

Energy Efficiency and Sustainability in Biscuit Making Machines

The contemporary biscuit making machines are characterized by their adept utilization of advanced insulation technologies to minimize energy wastage and optimize production processes. Insulation materials, such as high-density polyurethane foam, are strategically employed in the construction of these machines to ensure maximum heat retention within the baking chambers. By mitigating heat loss during the baking cycle, these insulating materials not only facilitate energy conservation but also contribute to the overall efficiency of the biscuit making process.

The advent of sophisticated control systems in modern biscuit making machines has revolutionized the landscape of energy efficiency in the food industry. These systems, equipped with state-of-the-art sensors and actuators, enable real-time monitoring and adjustment of various parameters, including temperature, humidity, and airflow, within the baking chambers. By maintaining precise control over these variables, manufacturers can optimize resource utilization while ensuring consistent product quality.

In the pursuit of sustainability, manufacturers of biscuit making machines are increasingly exploring alternative energy sources to power their equipment. Solar panels, for instance, are being integrated into the design of these machines to harness clean and renewable energy from the sun. By supplementing conventional power sources with solar energy, manufacturers not only reduce their carbon footprint but also mitigate the reliance on fossil fuels, thereby contributing to the global transition towards a greener future.

In an era characterized by heightened environmental consciousness, manufacturers of biscuit making machines are embracing lifecycle assessment methodologies to evaluate the environmental footprint of their products comprehensively. By conducting detailed analyses of the raw materials, manufacturing processes, and end-of-life disposal strategies associated with their machines, manufacturers can identify opportunities for design optimization and resource efficiency.

Innovations in Biscuit Making Machines for 2024

In the dynamic landscape of industrial food machinery, innovation is the driving force behind enhanced productivity, efficiency, and product diversification. As we venture into 2024, several groundbreaking innovations have emerged in the realm of biscuit making machines, revolutionizing the way small businesses approach confectionery production. Here are some notable advancements shaping the future of biscuit manufacturing:

Traditional biscuit making processes often entail labor-intensive dough preparation and handling tasks. However, recent advancements in automation technology have introduced integrated dough handling systems that streamline production workflows. From mixing and kneading to portioning and shaping, these automated systems offer unparalleled precision and consistency, minimizing human intervention and maximizing output efficiency.

In response to growing sustainability concerns and escalating energy costs, manufacturers are prioritizing the development of energy-efficient baking technologies. Modern biscuit making machines are equipped with innovative heating elements, insulation materials, and temperature control mechanisms that optimize energy utilization without compromising baking performance. These eco-friendly innovations not only reduce operational expenses but also align with the industry's commitment to environmental stewardship.

The advent of Industry 4.0 has ushered in a new era of smart manufacturing, redefining the capabilities of biscuit making machines. Embedded sensors, data analytics, and machine learning algorithms empower operators to monitor and optimize production processes in real-time. From predictive maintenance to recipe customization, digitalized biscuit making machines offer unprecedented levels of flexibility, agility, and responsiveness, enabling small businesses to adapt to evolving market demands with ease.

Consumer preferences are becoming increasingly diverse and discerning, prompting manufacturers to incorporate customization and personalization features into biscuit making machines. Modular designs, interchangeable components, and programmable settings allow producers to create a wide array of biscuit shapes, sizes, flavors, and textures to cater to niche markets and individual preferences. This versatility not only enhances product appeal but also fosters brand loyalty and customer engagement in an ever-evolving marketplace.

Troubleshooting Common Issues with Biscuit Making Machines

Even the most reliable Cookie Making Machine may encounter occasional issues. Understanding common problems and their solutions can minimize downtime and keep your production on track. Here are some frequently asked questions and troubleshooting tips:

Q: My machine is producing irregularly shaped biscuits. What could be the problem? A: Irregular biscuit shapes often result from improper dough consistency or misalignment of cutting mechanisms. Check the dough consistency and adjust as needed to ensure it flows smoothly through the machine. Inspect the cutting blades and nozzles for any misalignment or damage, and realign or replace them as necessary.

Q: The machine is jamming frequently during operation. How can I resolve this issue? A: Frequent jams may indicate issues with dough consistency, conveyor alignment, or improper lubrication. Ensure the dough is of the correct consistency and free from any lumps or air pockets. Check the conveyor belts for proper alignment and tension, and adjust as needed. Lubricate the moving parts according to the manufacturer's guidelines to reduce friction and prevent jams.

Q: The biscuits are coming out too soft or too hard. What adjustments should I make? A: Biscuit texture is influenced by factors such as dough composition, baking temperature, and conveyor speed. Experiment with different dough recipes to achieve the desired texture. Adjust the baking temperature and conveyor speed to achieve optimal baking conditions for your recipe. Regularly monitor the baking process and make adjustments as needed to maintain consistent quality.

References

1.Baker Perkins - www.bakerperkins.com

2.GEA Group - www.gea.com

3.Bühler Group - www.buhlergroup.com

4.Reading Bakery Systems - www.readingbakery.com

5.Haas-Meincke (part of Bühler Group) - www.haas.com