Nutrition Bar Production Line

A nutrition bar production line typically involves a series of steps that transform raw ingredients into finished nutrition bars. It's important to note that the exact steps and equipment used in a nutrition bar production line can vary depending on the specific recipe and production scale.

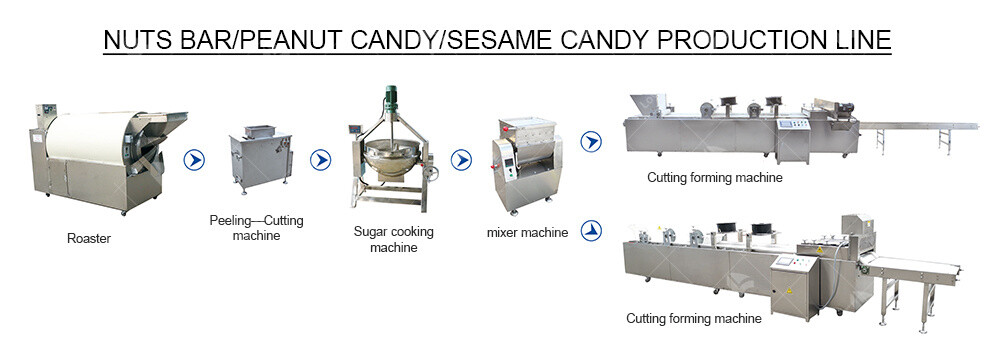

Flow Chart Of Nutrition Bar Production Line

1.Puffing —— 2. Drying —— 3. Sugar Boiled Pot —— 4. Oil Sugar Electromagnetic Insulation Pot —— 5. Electromagnetic Sugar Cooker —— 6. Weighing Feeder —— 7. Temperature Control Mixer —— 8. Hoist —— 9.Automatic Cutting Machine —— 10.Cooling —— 11.Auto Packing

Functions Of Nutrition Bar Production Line

1.Ingredient Preparation: Raw ingredients such as nuts, seeds, grains, and dried fruits are typically cleaned, sorted, and roasted or toasted as needed to improve their texture and flavor.

2.Mixing: The prepared ingredients are then mixed together in the correct proportions to form the base of the nutrition bars. Other ingredients such as protein powder, sweeteners, and flavorings may also be added at this stage.

3.Forming: The mixed ingredients are then fed into a machine that forms the bars into the desired shape and size. This can be done using a mold or a compression roller.

4.Baking or Cooling: Depending on the recipe, the formed bars may need to be baked in an oven or cooled in a refrigerator to set their shape and texture.

5.Coating and Packaging: Once the bars are cooled, they may be coated in chocolate, yogurt, or other toppings and individually packaged for sale.

6.Quality Control: Throughout the production process, quality control measures should be in place to ensure that the finished bars meet the desired standards for taste, texture, and nutritional content.

7.Storage and Distribution: The finished nutrition bars are then stored in a warehouse or other facility until they are shipped out to retailers or directly to customers.

Advantages Of Nutrition Line

Advantages Of Nutrition Line

Increased Efficiency | With a nutrition bar production line, you can streamline your production process, allowing you to make more bars in less time. This can help you meet demand and increase your output. |

Consistency | Production lines can help ensure consistency in the size, shape, and weight of each bar. This can be important for maintaining the quality of your product and meeting customer expectations. |

Cost-Effective | By automating the production process, you can save on labor costs, reduce waste, and optimize your use of raw materials. |

Customization | With a nutrition bar production line, you can easily customize your bars to meet the needs of different markets or customers. This flexibility can help you stay competitive and meet changing demand. |

Quality Control | Production lines can incorporate quality control measures to ensure that each bar meets your company's standards for taste, texture, and nutritional value. This can help you build a reputation for quality and consistency, which can be important for building customer loyalty. |

Performance And Other Instructions

A. The food contact location is made of stainless steel 304 material, which meets the food QS and pharmaceutical GMP hygiene requirements.

B. Double frequency conversion system control, bag length is set and cut immediately, saving time and film.

C. High-sensitivity electric eye automatic tracking, no need to manually adjust after setting, sealing and cutting size, accurate position, strong and beautiful sealing.

D. Temperature independent PID intelligent control, stable temperature control, better suitable for various packaging materials.

E. Color touch screen display, positioning shutdown, automatic fault diagnosis, the display is clear at a glance.

F. Intelligent human nature parameter design, ordinary personnel can use it skillfully in a short time. Reduce the professional skills requirements of operators.

G. A variety of cutting packaging shapes: straight, popcorn, corrugated, continuous bag, etc.

H. Suitable for moon cakes, bread, biscuits, candies, medicines, daily necessities, hardware parts, paper boxes, plastic products or all kinds of solid objects with regular shapes.