How are cereal bars made?

Now that the public has realized the importance of health, they are paying more and more attention to health, and they have begun to make corresponding adjustments in their diet. Grains have been recognized by the public, and foods made from grains have become the most popular among consumers. One of the food.

All kinds of cereal bars are made of cereals, which are convenient to eat and have a rich taste. They are now used by many consumers as breakfast foods or daily snack foods. So how are cereal bars made?

How are cereal bars made?

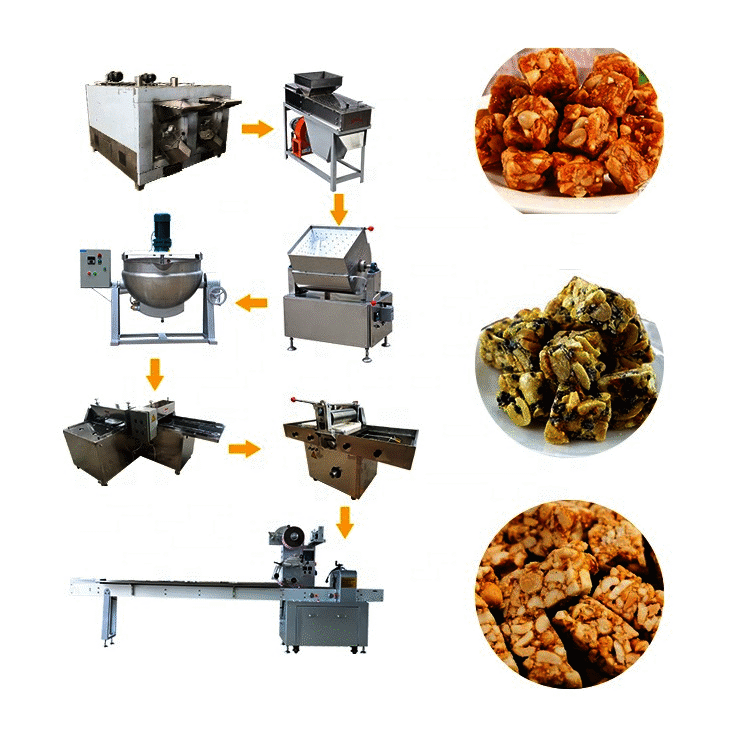

We are a professional food manufacturer with very rich experience in the cereal bar industry. The cereal bars we produce have become one of the favorite foods of many consumers. But now there are more and more people engaged in this industry, and the competition is getting fiercer. In order to stand out in the market, we decided to use the Cereal Bar Production Line for production after negotiation. The equipment can produce delicious cereal bars through production processes such as boiling sugar, molding pressing, baking, cutting, cooling, and coating.

The operation method of this production line is very simple, our workers easily learned to operate, the following is the method of making cereal bars on this production line:

The raw materials required for the production of cereal bars are nuts, dried fruits, corn, oats, sugar, etc. These ingredients are first pretreated.

Cook the sugar according to the recipe. This step is carried out in the sugar cooker, boil slowly on low heat, and require constant stirring. The prepared syrup is added with edible gum, oil, condensed milk, etc., and continuously heated and stirred to make it into a binder for cereal bars.

Next, add dried fruits, dried fruits, etc. to the adhesive and mix them evenly. After that, the prepared raw materials are transported into the roller press, and these raw materials are pressed into a cake shape, which is very tightly bonded.

After that, the extruded food will enter the oven for baking. High-temperature baking can cause the moisture in the cereal bar to lose and form a more crispy taste. Before the cereal bar is cooled, immediately cut it into a fixed shape. Then cool down.

In order to make the cereal bars richer, it is necessary to add a coating on the outer surface of the cereal bars. The coating is usually chocolate, yogurt, and condensed milk, etc. The cereal bars are immersed in these raw materials, and then taken out for cooling. Take a delicious coating.

The last step is to use the packaging machine for packaging.

The cereal bars produced by the cereal bar equipment have a very rich taste and high nutrient content. They have received unanimous praise from everyone. We also decided to use the equipment for a long time.

Cereal bar equipment has many advantages:

1. The equipment is made of 304 stainless steel, which is easy to clean and the quality is very reliable.

2. It can be processed to produce cereal bars, protein bars, energy bars and other foods with a wide range of uses.

3. The production is highly automated and the production efficiency is high.

4. Simple operation and convenient use.

5. There is no "three wastes" problem, environmental protection and pollution-free.

6. It can be customized and the usage is flexible and changeable.

Using the Cereal Bar Production Line can bring us a lot of convenience, the production quality has been effectively improved, and it has received a very high evaluation in the industry. Our cereal bar food has also become a hot food, and the economic benefits have been significantly improved.

Science and technology are the primary productive forces. Only by using high-quality equipment can we gain a broader market. I believe this production line will further promote our development!