Can fruit be dehydrated in the microwave?

Fruit is an essential food to replenish the nutrients of the human body. It contains water, vitamins, antioxidant compounds, carbohydrates, dietary fiber, and other nutrients, which are beneficial to human health. Still, fresh fruit cannot be stored for a long time, so Dried Fruit, a form that can be stored for a long time, is also popular.

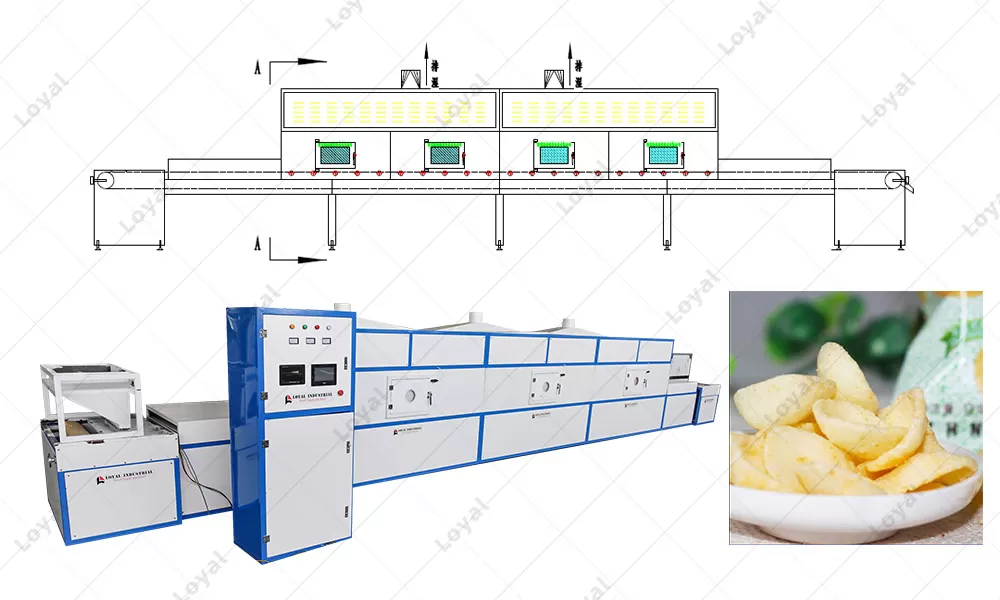

There are also many people at home to start making Dried Fruit themselves, but most of the Dried Fruit we eat are produced from the Fruit Drying plant, so Industrial Drying Machines are used to process the fruit? Can it be made with Microwave Dryer Machine?

Can fruit be dehydrated in the microwave?

Microwave Drying Technology is a new type of drying method. Microwave Drying Technology is penetrating and does not require heat conduction when heating. The medium can be heated inside and outside simultaneously; the temperature difference between inside and outside of the material is slight.

The heating is uniform so that the condition of external scorching and internal growth will not occur in conventional heating. The heating speed is breakneck, and the drying quality is greatly improved. For foodstuffs with moisture content below 30%, the drying speed can be shortened hundreds of times.

The composition structure of Microwave Drying Equipment includes a cranial chamber, oven door, electrical circuit, magnetron, timer, power distributor, interlock micro switch, thermal circuit breaker, Microwave Drying Machine is now used in the food industry, material chemical industry, medical industry, mineral extraction industry, etc.

Microwave Drying Machine can be customized according to the needs of customers, control the maximum temperature of the transmission belt ≤ 200 ℃, microwave frequency between 2.45GHz ± 25MHz; at the same time, Microwave Drying has a touch screen display, control, with automatic and manual dual operation, more convenient and reliable practice.

Microwave Vacuum Drying Equipment adopts infrared and thermocouple thermometer and humidity measuring instrument to measure the temperature and humidity inside the kiln. The microwave dryer can achieve precise control throughout the operation, and it has an automatic fabric, receiving, and dust removal system.

Advantages of Industrial Microwave Vacuum Dryer.

Advantages of Industrial Microwave Vacuum Dryer. | |

| 1 | Adopt unique microwave source and Microwave Control Technology to ensure stable and continuous operation of the Microwave System and long service life. |

| 2 | Adopt the standard and high efficient Microwave Systems to make the material dry evenly and avoid the phenomenon of local high temperature. |

| 3 | Dryer For Food Products adopts the original mathematical model and scientific cavity design, with high dehydration efficiency. |

| 4 | Industrial Microwave Systems microwave shielding technology is safe and reliable; microwave leakage <2mw/cm is better than the national standard. |

| 5 | Microwave Drying Of Food has high production efficiency, energy-saving, and can ensure that the material is free of pollution, to achieve safe and clean production. |

Microwave Vacuum Drying Equipment is mainly used for dehydration and drying of high value-added and heat-sensitive agricultural and sideline products, health care products, food, medicinal materials, fruits and vegetables, chemical raw materials, etc.; for a low-temperature concentration of chemical products, removal of crystalline water, drying of enzyme preparations, etc.; vacuum extraction of Chinese herbal medicine; for laboratories in research institutes.

Industrial Microwave Systems are used to extend the shelf life of food, preserve the original flavor and nutrients of food, retain the physiological activity of raw materials, enhance the functionality of healthy food, and increase the added value of agricultural and sideline products.

The Fruit Drying and Manufacturing Process is divided into the following processes.

Raw material selection → cleaning and slicing → color protection, hardening, scalding → deoxidation, throat flavor → vacuum canning → drying, and softening → dried fruit packaging.

The fruit microwave drying process needs to set the Microwave Dryer Machine temperature, humidity, and other drying mode parameters. Generally, the best effect is to bake at 55℃-75℃ for 15-20 hours, until the moisture content of dried fruits is around 10%-15%.

The microwave drying process of fruits has three stages:

| In the first stage, the Microwave Drying temperature is set at 60℃, humidity is set at 35%, a mode is drying + moisture removal, baking time is 2 hours. |

| The second stage, Microwave Drying Equipment temperature 65℃, the humidity setting 25%, mode selection drying + moisture removal, baking for about 8 hours. |

| The third stage, Dryer For Food Products temperature raised to 70 ℃, the humidity setting 15%, mode using drying + moisture removal, baking time of 8 hours. |

| The fourth stage, Microwave Drying Of Food temperature set to 60 ℃, humidity set to 10%, continuous dehumidification mode baking for about 1 hour, drying is completed to be back to soft packaging into bags. |

After the fruit is dried with Vacuum Drying Equipment, it retains the original taste and nutrition of the fruit, can eat all the fiber of the peel, and there is no risk of protease and unpolymerized tannins harming the digestive tract and can concentrate all the mineral components in Microwave Drying Technology and retain most of the antioxidant components. Dried fruit can also be stored for long periods, making it easy to transport, carry and mix with other things, making it a great snack.

The above is the Microwave Drying Process of the Microwave Drying Factory to produce dried fruits. It can be seen that the use of Microwave Drying Technology is easy to automate and control and can improve the quality of the product.

Our company is a professional Microwave Dryer Manufacturer with many years of experience in Microwave dryer manufacturing technology. Our Microwave Dryer Machine is currently sold in domestic and overseas markets and is gaining more and more attention in various fields of drying. Microwave Drying Equipment

2021 Microwave Drying Equipment customer transaction case:

Commercial Microwave Drying Machine customer cases in 2021 | |

| 1 | 600-700kg/h Microwave Vacuum Dryer Machine sold in South Africa |

| 2 | 800kg/h Industrial Microwave Vacuum Dryer for sale in Russia |

| 3 | 1t/h high-quality Microwave Vacuum Oven for sale in the USA |

| 4 | 500-700kg/h Professional Dryer For Food Products for sale in Thailand |

| 5 | 1-2t/h Industrial Drying Machines for sale in France |

2021 Customer Repurchase Case of Vacuum Drying Equipment | |

| 1 | 500kg/h Microwave Drying Of Food for sale in Indonesia |

| 2 | Sale of 800kg/h Microwave Wood Drying Machine in Germany |

| 3 | Singapore selling 600kg/h cost-effective Microwave Dryer Machine |

If you want to open a Microwave Drying Plant and ask questions about Microwave Technology, please feel free to contact us; we can provide you with professional advice on Microwave Technology and give you a cost-effective Microwave Dryer Price.

We will provide you with professional cookie production line advice, cost-effective Microwave Dryer price, and perfect after-sales service. We look forward to cooperating with you.