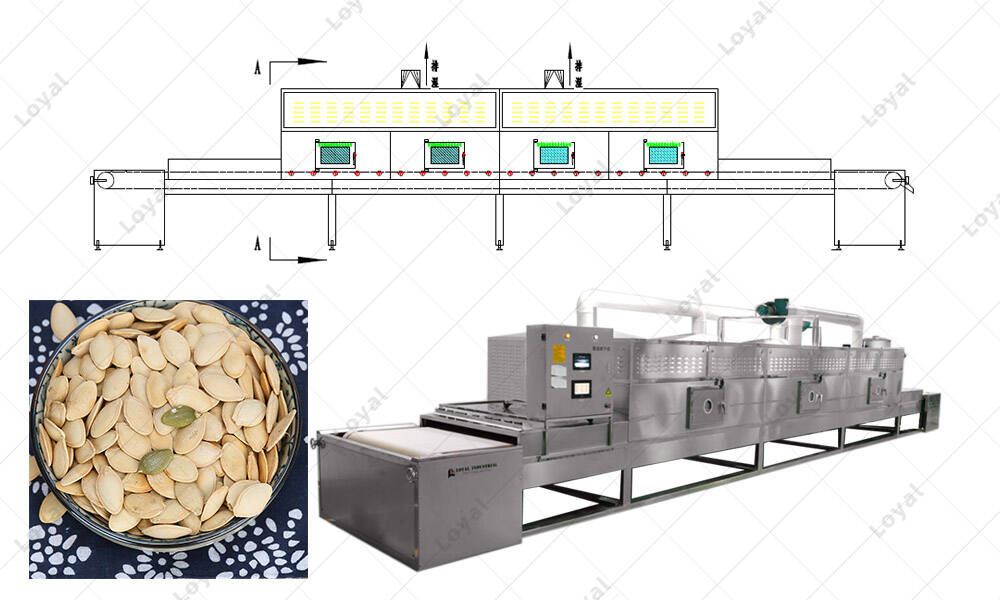

Industrial Microwave Dryer For Baking Pumpkin Seeds

As one professional industrial microwave dryer for baking pumpkin seeds manufacturer, we can offer small, medium and large industrial microwave dryer for baking pumpkin seeds for sale. The pumpkin seeds microwave dryer equipment has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements.

Industrial Microwave Dryer For Baking Pumpkin Seeds Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Industrial Microwave Dryer For Baking Pumpkin Seeds |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

| Delivery Detail | 20days/Microwave equipment assembly completed |

| Packaging Details | Export-compliance microwave equipment packaging |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sale Team | Industrial Microwave Date Drying Sterilizing Machine Team |

| Honor | A number of national microwave equipment patents |

| Technology | 8 Years Of Microwave Technology |

Industrial Microwave Dryer For Baking Pumpkin Seeds Detail Introduction :

As one professional industrial microwave dryer for baking pumpkin seeds manufacturer, we can offer small, medium and large industrial microwave dryer for baking pumpkin seeds for sale. The pumpkin seeds microwave dryer equipment has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements.

The microwave drying and sterilizing equipment for pumpkin seeds has a fast heating speed. Microwave heating makes the heated object itself a heating body, which is called an internal heating method. It does not require the process of heat conduction. Pumpkin seeds microwave dryer equipment adopts low temperature sterilization and no pollution. Microwave energy itself will not contaminate food, and the double sterilization effect of microwave thermal effect can kill bacteria at a lower temperature, which provides a heat sterilization method that can maintain more nutrients in food. Pumpkin seeds microwave drying equipment evenly heats conventional heating, in order to increase the heating speed, it is necessary to increase the heating temperature, which is prone to the phenomenon of external coke and endogenesis.

WHAT ARE CHARACTERISTICS OF INDUSTRIAL MICROWAVE DRYER FOR BAKING PUMPKIN SEEDS?

Characteristics Of Industrial Microwave Dryer For Baking Pumpkin Seeds | |

| 1 | Rapid heating, uniform heating, short drying time, and improved product quality. |

| 2 | Energy saving and high efficiency, no environmental pollution. |

| 3 | Pumpkin seed microwave dryer adopts PLC automatic control, adjustable microwave power, automatic temperature control system, automatic conveyor belt correction system, transmission frequency conversion speed regulation system, etc., one-key setting, the system is fully automatic, the operation is simple, and the labor intensity is low. |

| 4 | Pumpkin seed microwave dryer is mainly made of stainless steel plate, which is strong and sturdy, beautiful in appearance, convenient for cleaning and simple in daily maintenance. |

HOW TO DRY PUMPKIN SEEDS?

Microwaves are electromagnetic waves that generate high-frequency electromagnetic fields. The heating medium material consists of polar molecules and non-polar molecules. The water molecules in the material are polar molecules. Under the action of the electromagnetic field, the polar molecules change from the original random distribution state to the polarity. according to the polarity of the electric field. Molecular motion and friction against each other generate energy that continuously increases the temperature of the material. A series of physicochemical processes are produced for heating and puffing to achieve the purpose of thermal drying and drying of pumpkin seeds.

WHAT IS THE ROLE OF PUMPKIN SEEDS?

Role Of Pumpkin Seeds | |

| 1. Detoxification: | It contains vitamins and pectin. Pectin has good adsorption properties, which can bind and eliminate bacterial toxins and other harmful substances in the body, such as lead, mercury and radioactive elements in heavy metals, which can play a detoxification role. |

| 2.Protect Gastric Mucosa And Help Digestion: | pectin contained in pumpkin can also protect gastric mucosa from rough food stimulation, promote ulcer healing, and is suitable for patients with gastric diseases. The ingredients contained in pumpkin can promote bile secretion, strengthen gastrointestinal motility, and help food digestion. |

| 3.Prevention And Treatment Of Diabetes And Lowering Blood Sugar: | pectin contained in pumpkin can also protect gastric mucosa from rough food stimulation, promote ulcer healing, and is suitable for patients with gastric diseases. The ingredients contained in pumpkin can promote bile secretion, strengthen gastrointestinal motility, and help food digestion. |

| 4.Eliminate Carcinogens: | Pumpkin can eliminate the mutation effect of carcinogen nitrosamines, has anti-cancer effect, and can help the recovery of liver and kidney functions, and enhance the regeneration ability of liver and kidney cells. |

| 5.Promote Growth And Development: | Pumpkin is rich in zinc, which participates in the synthesis of nucleic acid and protein in the human body, is an inherent component of adrenal cortex hormones, and is an important substance for human growth and development. Raw pumpkin seeds can relieve symptoms of prostatitis. Chronic prostatitis is a relatively stubborn male disease. But not without a cure. Pumpkin seeds are cheap, effective and safe to take, and are worthy of trial for patients with chronic prostatitis (or hyperplasia), but their long-term efficacy needs to be further verified. |

| 6. | Pumpkin seeds have a good effect on killing internal parasites (such as pinworms, hookworms, etc.). Also has a good killing effect on schistosomiasis |

PUMPKIN SEEDS BELT DRYER TECHNICAL PARAMETERS

Pumpkin Seeds Belt Dryer Technical Parameters | ||||||||

| Type | LY-1.2-8 | LY-1.2-10 | LY-1.6-8 | LY-1.6-10 | LY-2-8 | LY-2-10 | LY-2-20 | |

| Quantity Of Unit | 4 | 5 | 4 | 5 | 4 | 5 | 10 | |

| Belt Width(m) | 1.2 | 1.6 | 2 | |||||

| Length Of Drying Section(m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 | |

| Thickness Of Raw Material(Mm) | ≤60 | |||||||

| Operation Temperature(°C) | 50-140 | |||||||

| Steam Pressure(Mpa) | 0.2-0.8 | |||||||

| Steam Consume(Kg/h) | 120-300 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | 450-1200 | |

| Drying Time(h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.5-3 | |

| Drying Strength(Kg/h) | 60-160 | 80-220 | 75-220 | 95-250 | 100-260 | 120-300 | 240-600 | |

| Power Equipped(Kw) | 11.4 | 13.6 | 11.4 | 13.6 | 14.7 | 15.8 | 36.8 | |

| Overall Dimensions | L(m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| W(m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 | |

| H(m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 | |

| Weight(Kg) | 4500 | 5600 | 5300 | 6400 | 620 | |||

Remark:

1. Parameters above in the table are regular model for reference;

2. We could make special model / size according to the customer's actual situation or requirement, please contact KODI sales team to konw more details about Pumpkin Seeds belt dryer.

WHICH MARKET DID THE LOYALSMALL SCALEINDUSTRIAL MICROWAVE DRYER FOR BAKING PUMPKIN SEEDS SOLD?

LOYAL's share of pumpkin seeds continuous microwave oven exported to international markets has steadily increased. According to the export goods trade data in 2021, Loyal's export market share in the international market is 86.5%, of which the Industrial microwave pumpkin seeds tunnel dryer export market share is 20.8%, the export market share in the Americas is 30.2%, and the export market share in Asia is 35.5%. If you are interested in a meat dryer, please contact us today, we offer you the most cost-effective turnkey solution.

Customer Have Formula Request Of Pumpkin Seeds Continuous Microwave Oven | |

1 | China 300t/Year Industrial Microwave Pumpkin Seeds Tunnel Dryer |

2 | 1T/H Pumpkin Seed Microwave Dryer For Sale In Puerto Rico |

3 | 1T/H Pumpkin Seed Microwave Dryer For Sale In Bolivia |

4 | 800Kg/H Automatic Microwave Pumpkin Seed Dryer For Sale In Argentina |

5 | 2T/H Automatic Microwave Pumpkin Seed Dryer For Sale In Benin |

6 | 2T/H PLC Control Pumpkin Seed Automatic Microwave Drying Machine For Sale In British Indian Ocean Territory |

7 | 2T/H PLC Control Pumpkin Seed Automatic Microwave Drying Machine For Sale In Chile |

Cooperated Customer For Laboratory Machine Of Automatic Microwave Pumpkin Seed Dryer | |

1 | Senegal 200Kg/H Industrial PLC Control Pumpkin Seed Automatic Microwave Drying Machine |

2 | 100-200Kg/H PLC Control Pumpkin Seed Automatic Microwave Drying Machine For Sale In Côte d'Ivoire |

3 | 300-400Kg/H Automatic Microwave Pumpkin Seed Dryer For Sale In Sold In Russia |

4 | 500Kg/H Automatic Microwave Pumpkin Seed Dryer For Sale In Sold In Denmark |

5 | 600Kg/H Automatic Microwave Pumpkin Seed Dryer For Sale In Dominica |

6 | 100-200Kg/H PLC Control Pumpkin Seed Automatic Microwave Drying Machine For Sale In Egypt |

7 | 300-400Kg/H Automatic Microwave Pumpkin Seed Dryer For Sale In Sold In Ethiopia |

Cooperated Customer Request Engineer Installation At 2021 | |

1 | 1T/H Factory Direct Sale Industrial Tunnel Microwave Pumpkin Seed Drying Machine For Sale In Uzbekistan |

2 | 1000kg/h Industrial Automatic Microwave Pumpkin Seed Dryer For Sale In Senegal |

3 | Mozambique 1T/H Automatic Microwave Pumpkin Seed Dryer Machine |

4 | 1T/H Thai Automatic Microwave Pumpkin Seed Drying Machine |

5 | Uzbekistan 1T/H Automatic Microwave Pumpkin Seed Drying Machine |

6 | 2T/H Factory Direct Sale Industrial Tunnel Microwave Pumpkin Seed Drying Machine For Sale In Germany |

7 | 2T/H Factory Direct Sale Industrial Tunnel Microwave Pumpkin Seed Drying Machine For Sale In Guinea |

Cooperated Customer With Microwave Dryer Machine For Pumpkin Seed Technology At 2021 | |

1 | Nigeria 500Kg/H Microwave Dryer Machine For Pumpkin Seed |

2 | Austria Sells Microwave Dryer Machine For Pumpkin Seed 1000kg/h |

3 | Microwave Dryer Machine For Waste Water Pumpkin Seed For Sale In Pakistan 1000kg/h |

4 | 1T/H Microwave Dryer Machine For Pumpkin Seed For Sale In India |

5 | 2T/H Microwave Dryer Machine For Pumpkin Seed For Sale In Israel |

6 | 2T/H Microwave Dryer Machine For Pumpkin Seed For Sale In Jamaica |

7 | 2T/H Microwave Dryer Machine For Pumpkin Seed For Sale In Morocco |