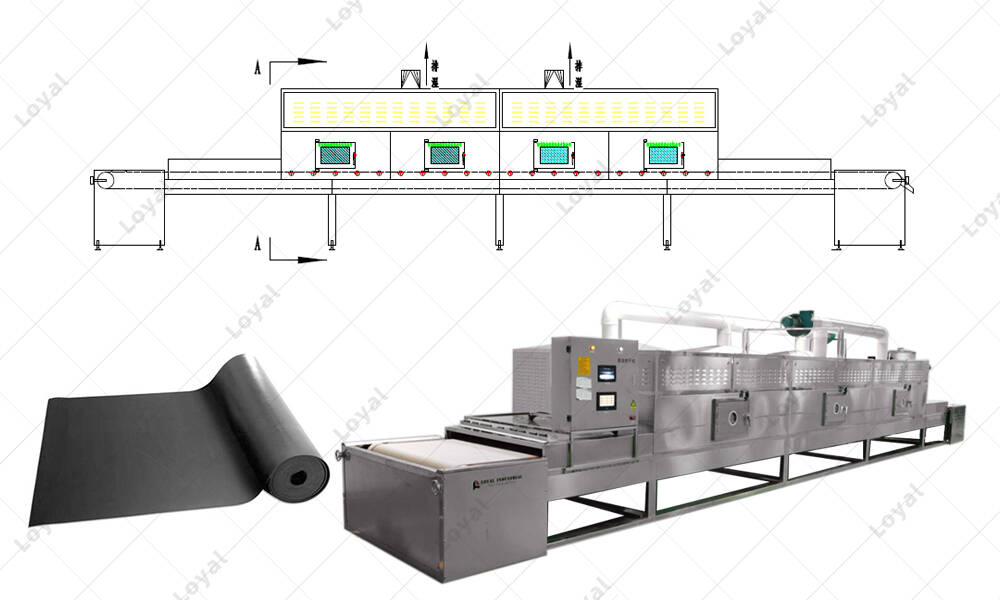

High Quality Continuous Microwave Rubber Mattress Drying Machine

As a latex High Quality Continuous Microwave Rubber Mattress Drying Machine manufacturer, our high quality industrial continuous microwave rubber mattress drying machine has penetrating performance inside and outside the media heating at the same time. Industrial rubber drying and dehydration machine can saving drying time and avoid the raw material becoming metamorphism,and the drying effect is good for rubber insects,meat, tea,mushroom and so on. Microwave rubber heating equipment is used in fast food,chemical rubber,mineral,pebbles and other products that require rapid heating.

The microwave rubber mattress heating equipment uses electric energy as an energy source,and uses a magetron to convert electrical energy into microwave,and directly performs non-contract heating on the materials.The rubber latex tunnel dryer adopts microwave drying process to dry. It is a new type of drying technology equipment.The rubber microwave drying disadvantages is fast drying speed and good quality. It has become the preferred latex drying equipment for many latex customers. All in all, only the perfect combination of formula-process-equipment can produce high-quality products.

High Quality Continuous Microwave Rubber Mattress Drying Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Continuous Microwave Rubber Mattress Drying Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

| Packaging Details | High Quality Continuous Microwave Rubber Mattress Drying Machine |

High Quality Continuous Microwave Rubber Mattress Drying Machine Detail Introduction :

High Quality Continuous Microwave Rubber Mattress Drying Machine

As a latex drying machine manufacturer, our high quality industrial continuous microwave rubber mattress drying machine has penetrating performance inside and outside the media heating at the same time. Industrial rubber drying and dehydration machine can saving drying time and avoid the raw material becoming metamorphism,and the drying effect is good for rubber insects,meat, tea,mushroom and so on. Microwave rubber heating equipment is used in fast food,chemical rubber,mineral,pebbles and other products that require rapid heating.

Introduction Of Continuous Microwave Rubber Mattress Drying Machine

The microwave rubber mattress heating equipment uses electric energy as an energy source,and uses a magetron to convert electrical energy into microwave,and directly performs non-contract heating on the materials.The rubber latex tunnel dryer adopts microwave drying process to dry. It is a new type of drying technology equipment.The rubber microwave drying disadvantages is fast drying speed and good quality. It has become the preferred latex drying equipment for many latex customers. All in all, only the perfect combination of formula-process-equipment can produce high-quality products.

What Is Technical Parameter Of Industrial Microwave Rubber Mattress For Sale?

Technical Parameter Of Industrial Microwave Rubber Mattress Dehydration Machine | ||||||

Model | Working | Input Power | Microwave Output | Size | Dehydrated | Sterilization |

LY-12 | 2450MHz | 18kw | 12kw | 7200x650x1800mm | 12kg/hr | 100-150kg/hr |

LY-15 | 2450MHz | 20kw | 15kw | 8300x720x1800mm | 15kg/hr | 120-180 kg/hr |

LY-20 | 2450MHz | 26kw | 20kw | 8500x750x1800mm | 20kg/hr | 180-250 kg/hr |

LY-30 | 2450MHz | 36kw | 30kw | 10500x950x2000mm | 30kg/hr | 280-350 kg/hr |

LY-40 | 2450MHz | 46kw | 40kw | 10500x1050x2000mm | 40kg/hr | 380-450 kg/hr |

LY-50 | 2450MHz | 58kw | 50kw | 12200x1200x2000mm | 50kg/hr | 480-550 kg/hr |

How About the Application Of Industrial Microwave Silica Gel Rubber Dehydration Machine?

The core of rubber microwave drying equipment is a microwave generator. At present, the frequency of latex microwave drying is mainly 2450 MHz. Continuous rubber microwave oven is mostly used in the drying of chemical, food, agricultural and sideline products, wood, building materials, paper products and other industries. It can also be used for food, agricultural and sideline products, etc. sterilization.

Application Of Industrial Rubber Latex drying equipment | |

1 | Insects such as locusts, locusts, earthworms, black soldier fly larvae, centipedes, scorpions. |

2 | All kinds of teas,herbs, flowers, green leaves,etc. |

3 | Gel-like materials, such as silicone, rubber and latex, etc. |

4 | Various dried meat, like beef, pork, chicken,duck, fish etc. |

5 | Powder for various material,such as spices, other food additives. |

6 | Agricultural products,such as china date,nuts,grains,peanut,etc. |

7 | Chemical material,medicine tablet or pill,such as watered pills,water-honey bolus,honeyed bolus,condensed pill and Tibetan pill,etc. |

How Is Advantages Of Industrial Microwave Silica Gel Tunnel Dryer?

Advantages Of Industrial Microwave Silica Gel Tunnel Dryer | |

1 | The industrial rubber microwave locust dehydrator greatly shortens the processing time, is easy to control and simple to operate. |

2 | The microwave silica drying and dehydrating machine has high processing efficiency, low energy consumption, small footprint and low cost. |

3 | The temperature of the dried rubber mattress is uniform and the expansion is good. The industrial rubber mattress microwave machine has a high degree of automation and can run continuously for 24 hours. |

4 | The latex industrial microwave oven adopt 304 stainless steel, compact structure, no energy dissipation, save energy. |

What Is Our Industrial Silica Gel Microwave Services?

Industrial Microwave Rubber Latex Services | |

1 | One year complete warranty. |

2 | Free consultation service before, during, and after sales. |

3 | Overseas installation and training of equipment maintenance and operating personally. |

4 | Free Project planning and design services upon clients' special demands. |

5 | Provide basic production techniques and formulas. |

6 | Debugging and inspecting of equipment until everything is functional before leaving the factory. |

Which Market Did The Loyal Industrial Microwave Rubber Latex Dehydration Machine?

Customer Case Of Large Scale Continuous Silica Gel Tunnel Dryer At 2021 | |

1 | 1000kg/h Thai industrial rubber belt dryer for Thailand customer |

2 | 1000kg/h large scale industrial latex drying equipment for sale in Uzbekistan |

3 | 1500kg/h automatic silica gel drying equipment for sale in Nigeria |

4 | 1000kg/h microwave rubber drying equipment for factory in Canada |

5 | 1000kg/h industrial microwave rubber drying equipment for sale in Japan |

6 | English 1000kg/h fully automatic latex microwave drying equipment |

7 | Bangladesh 2000kg/h fully automatic latex microwave drying equipment |

Customer Case Of Continuous Industrial Latex Belt Dryer At 2021 | |

1 | Continuous industrial rubber drying equipment fully automatic 500kg/h in Algerian |

2 | 800kg/h industrial automatic industrial rubber belt dryer for sale in Senegal |

3 | 1000kg/h industrial drying latex equipment in pharmaceutical industry sold in Russia |

4 | 1000kg/h cost of latex microwave drying equipment sold in Japan |

5 | 2000kg/h industrial silica gel microwave price for factory for sale in Egypt |

6 | 1000kg/h industrial microwave rubber price for sale in Bolivia |

7 | Senegal 1000kg/h industrial fully automatic silica gel industrial sized microwave |

Customer Have Factory Case Of Industrial Rubber drying equipment At 2021 | |

1 | 1500kg/h industrial rubber drying equipment and systems for sale in Bolivia |

2 | Mozambique 1500kg/h industrial latex drying equipment |

3 | 1300kg/h industrial continuous latex belt dryer for sale in Brazil |

4 | 1500kg/h Thai microwave silica gel drying equipment for factory |

5 | Egypt 1000kg/h fully automatic industrial rubber microwave price |

6 | USA 1200kg/h microwave silica gel drying equipment |

7 | 800kg/h industrial microwave silica gel drying equipment for sale in Japan |