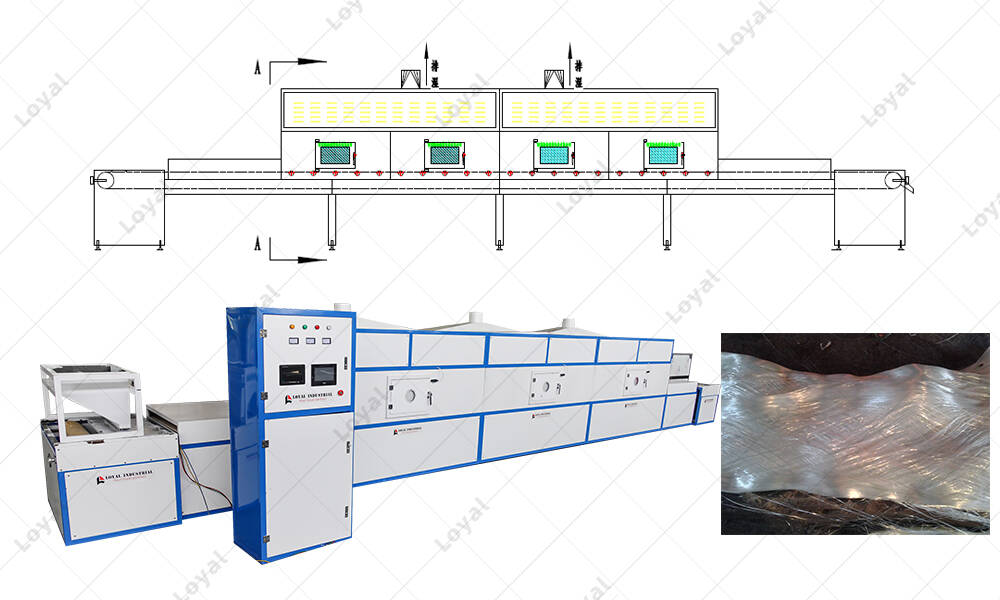

High Efficient Industrial Microwave Glass Fiber Drying Machine Microwave Glass Fiber Drying Oven

As a manufacturer of glass fiber drying machine, our continuous tunnel glass fiber drying machine is developed by a number of glass fiber drying machine technical engineers who have more than ten years of experience. Loyal has a number of glass fiber drying machine project technology patents, which can save dryer costs while improving good development in the glass fiber drying machine manufacturing industry.

High Efficient Industrial Microwave Glass Fiber Drying Machine Microwave Glass Fiber Drying Oven Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Industrial Microwave Glass Fiber Drying Machine Microwave Glass Fiber Drying Oven |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

| Delivery Detail | 20days/Microwave equipment assembly completed |

| Packaging Details | Export-compliance microwave equipment packaging |

| Team | Professional microwave technology team |

| Sale Team | Microwave Drying Sterilizing Machine Technical Team |

| Honor | A number of national microwave equipment patents |

| Technology | 8 years of microwave technology |

| Process | Ten years of microwave equipment manufacturing process |

High Efficient Industrial Microwave Glass Fiber Drying Machine Microwave Glass Fiber Drying Oven Detail Introduction :

As a manufacturer of glass fiber drying machine, our continuous tunnel glass fiber drying machine is developed by a number of glass fiber drying machine technical engineers who have more than ten years of experience. Loyal has a number of glass fiber drying machine project technology patents, which can save dryer costs while improving good development in the glass fiber drying machine manufacturing industry.

How Do You Dry Out Glass Fiber?

Glass fiber microwave drying machine can be designed according to the size and shape of yarn group, felt, cloth, blanket, etc., as well as different requirements and characteristics of drying temperature, film forming time, hardness and moisture content. There are three types of glass fiber drying equipment: crawler type continuous transmission, intermittent or intermittent traveling type, and microwave hot air mixing type. Compared with traditional drying equipment, it can save energy by about 30%, and can greatly improve fiber quality. The glass fiber drying equipment is divided into heating area, water extraction area and film forming area to meet the drying requirements of fibers. The glass fiber drying equipment adopts PLC to automatically control the drying temperature, humidity and drying time, and the human-machine interface adopts the touch screen type, which can flexibly set the drying process. The microwave power is designed according to the user's output and dehydration requirements. It is a fireproof board drying equipment with a high degree of automation.

What Is The Technical Parameters Of Glass Fiber Continuous Microwave Oven?

Technical Parameters Of Glass Fiber Continuous Microwave Oven | |||||

| No | Modle | Dehydration Capacity(Kg/h) | Power | Size L*W*H(mm) | Sterilization Capacity(Kg/h) |

| 1 | LY-12KW | 12kg/h | 12KW | 7010mm*840mm*1750mm | 120-150kg/h |

| 2 | LY-20KW | 20kg/h | 20KW | 9350mm*840mm*1750mm | 200-240kg/h |

| 3 | LY-40KW | 40kg/h | 40KW | 10520mm*1060mm*1750mm | 400-500kg/h |

| 4 | LY-80KW | 80kg/h | 80KW | 12860mm*1200mm*1750mm | 800-1000kg/h |

| 5 | LY-100KW | 100kg/h | 100KW | 15200mm*1200mm*1750mm | 1000-1250kg/h |

What’s The Parameter Of 40 Kw Microwave Glass Fiber Continuous Drying Oven?

40 Kw Microwave Glass Fiber Continuous Drying Oven | ||

| 1 | Equipment material | the whole machine is made of stainless steel |

| 2 | Electrical material: | national standard electrical device manufacturing |

| 3 | Equipment working power: | three-phase five-wire 380V±10% |

| 4 | Microwave power: | 40KW (adjustable) |

| 5 | Drying temperature | 60-100 degrees (adjustable and controllable) |

| 6 | Drying time | 3-10 minutes (adjustable) |

| 7 | Width of conveyor belt | 750mm |

| 8 | Transmission speed | 0 ~ 5 m/min (frequency conversion speed regulation) |

| 9 | Dimensions (length×width×height) | about 12890×1360×1750mm. |

Why Use Glass Fiber Microwave Dryer Machine To Dry Glass Fiber?

Functions And Features Of Glass Fiber Microwave Dryer Machine | |

| NO. | Functions And Features Of Glass Fiber Microwave Dryer Machine |

| 1 | The glass fiber has bright color and no yellowing phenomenon; |

| 2 | Good film formation and fast penetration; |

| 3 | The raw silk plied yarn has good tape formation; |

| 4 | The moisture content can reach below 1‰, suitable for drying packaged yarn, glass fiber cloth, chopped fiber, silk cake, ply yarn, aluminum silicate fiber mat, ceramic fiber, glass fiber post-treatment drying, glass fiber reinforced plastic curing Wait. |

Extensive Use Of Glass Fiber Industrial Microwave Dryer

Products Category That Can Be Dried In Glass Fiber Industrial Microwave Dryer | |

| 1 | Packaged Yarn Drying |

| 2 | Glass Fiber Cloth Drying |

| 3 | Chopped Fiber Drying |

| 4 | Plied Yarn Drying |

| 5 | Silk Cake Drying |

| 6 | Aluminum Silicate Fiber Mat Drying |

| 7 | Ceramic Fiber Drying |

| 8 | Glass Fiber Post-Treatment |

| 9 | Glass Fiber Reinforced Plastic Curing |

Application Of Glass Fiber Industrial Microwave Dryer Machine

Application Of Glass Fiber Industrial Microwave Dryer Machine | |

NO. | Application Of Glass Fiber Industrial Microwave Dryer Machine |

1 | Chemical Material,Medicine Tablet Or Pill,Such As Watered Pills,Water-Honey Bolus,Honeyed Bolus,Condensed Pill And Tibetan Pill,Etc. |

2 | Chemical Material,Medicine Tablet Or Pill,Such As Watered Pills,Water-Honey Bolus,Honeyed Bolus,Condensed Pill And Tibetan Pill,Etc. |

3 | Various Dried Meat, Like Beef, Pork, Chicken,Duck, Fish Etc. |

4 | Powder For Various Material,Such As Spices, Other Food Additives. |

5 | Agricultural Products,Such As China Date,Nuts,Grains,Peanut,Etc |

6 | Snack Food, Fruit Seeds, Grains, Peanuts, Chips,Etc. |

Glass Fiber Industrial Microwave Dryer Machine can be used for many material, for example, frozen meat, fresh shrimp, fish, grain, beans, piper, flower, wood and other material. It has function for drying and sterilizing. We can make solution for your detailed demand. | |

2021 Customer Order Glass Fiber Microwave Drying And Sterilizing Machihne Form:

| Customers Who Understand The Glass Fiber Drying Machine Processing Technology | |

| 1 | Glass Fiber Hot Air Dryer Drying Equipment For Glass Fiber For Sale In Afghanistan |

| 2 | China Fully Glass Fiber Dryer Vacuum Microwave Machine Dryer Machine Industrial Microwave Oven For Sale In Argentina |

| 3 | High Quality Most Popular Industrial Continuous Microwave Glass Fiber Drying Machine Tunnel Microwave Dryer For Sale In Comoros |

| 4 | Mini Industrial Glass Fiber Making Machine Spray Dryer Drying Machine For Sale In Afghanistan |

| 5 | Chemicals Drying Equipment Glass Fiber Dryer Industrial Pesticide Farm Chemicals Drying Equipment For Sale In Argentina |

Dealed Customers Who Purchase Big Output Glass Fiber Dryer Production Line In 2021 | |

| 1 | Customized Microwave Vacuum Drying Sterilization Glass Fiber Equipment For Chemical Industry For Sale In Congo |

| 2 | 50Kw Chemical Glass Fiber Microwave Drying Machine Equipment For Glass Fiber For Sale In Denmark |

| 3 | Tunnel Industrial Microwave Glass Fiber Drying Sterilization Machine Equipment For Sale In Congo |

| 4 | Customized High Efficiency Glass Fiber Drying Equipment Glass Fiber For Sale In India |

| 5 | Glass Fiber Microwave Sterilization Drying Equipment For Sale In Denmark |

Dealed Customer Have Plant Of Glass Fiber Drying Equipment In 2021 | |

| 1 | Tunnel Industrial Chemical Glass Fiber Microwave Drying Equipment For Sale In Fiji |

| 2 | High Efficiency Tunnel Microwave Vacuum Dryer Machine For Glass Fiber Vacuum Drying Oven Equipment For Sale In Fiji |

| 3 | High Efficient Microwave Industrial Glass Fiber Drying Machine Industrial Microwave Dryer For Sale In Germany |

| 4 | Belt Tunnel Drying Machine Glass Fiber Microwave Dryer Machine For Sale In Germany |

| 5 | Industrial Microwave Dryer Industrial Glass Fiber Drying Machine For Sale In Fiji |

Dealed Customer Whose Intruduction Of Old Customer Of Glass Fiber Drying Production Line In 2021 | |

| 1 | Stainless Steel Glass Fiber Spray Dryer Price Stainless Steel Spray Dryer For Sale In Laos |

| 2 | Microwave Drying Glass Fiber Class Sterilization Machine Equipment For Sale In Lebanon |

| 3 | Vacuum Drying Equipment For Vacuum Microwave Glass Fiber Drying Machine For Sale In Lesotho |

| 4 | Chemical Products Glass Fiber Microwave Conveyor Belt Dryer Machine For Sale In Mali |

| 5 | Glass Fiber Drying Box Braised Meat Tray Dryer Machine Drying Equipment For Sale In Nauru |