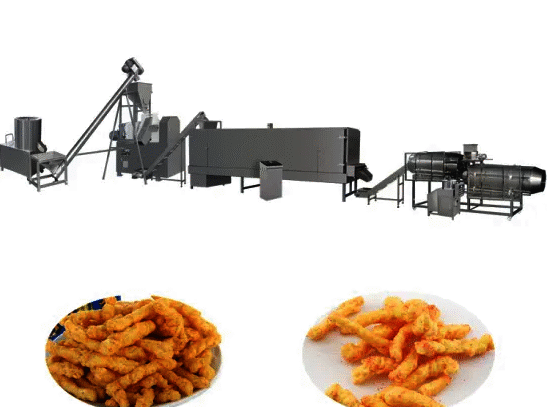

Kurkure processing technology and characteristics of the production line

Kurkure is an extruded snack with a crunchy taste and good texture. It is loved by consumers due to its delicious taste, rich nutrition, and good taste for both young and old, and its variety of flavors meets the different needs of consumers. Its market is very broad and has great potential for development.

As Kurkure is very popular, the Kurkure snack machine is also developing more and more. As the equipment for producing Kurkure, it has undergone many modifications and continuous improvement, and is commonly used in the food processing industry, and can process many types of snacks, and is now very popular in the market.

Kurkure Production Line mainly consists of a mixer, screw conveyor, single screw extruder, cutting machine, baking oven, cooling conveyor, and packing machine. The whole line is highly automated and easy to operate, and its process flow is as follows.

The line adopts twin and single screw extrusion technology to replace the traditional cooking process, including mixing, cooking, extruding, forming, flavoring and packaging, without a boiler, simple process, high efficiency, and low pollution.

(1) Mixing machine

The corn grits are mixed with water to prepare the flour for making Kurkure.

(2) Rotary die extruder

The corn flour is steamed, and the Kurkure is extruded from the mold. Compression and friction will generate a lot of heat. The rotating mold twists and curls the meal before extrusion to provide a product with a uniform texture.

(3) Automatic Fryer

Frying Kurkure in hot cooking oil, uniform frying makes the food taste crunchy and delicious.

(4) Cooling conveyor

Cools the fried Kurkure and reduces the temperature before packaging.

(5) Automatic seasoning system

Adding the desired seasoning to the fried and cooled Kurkure to give it different flavors.

(6) Automatic packaging machine

Pack Kurkure into beautifully printed bags with automatic gas flushing.

The line is mainly made of corn grits, which are fed into the rotary die head extruder by adding water to the flour mixer. In the extruder, the meal is heated, and the moisture content is reduced due to the superheat and pressure of the screw. The meal passes through the die and is cut to the desired length by the cutting knife. The kurkure is fried in cooking oil, then cooled and seasoned, the seasoning is sprayed on the kurkure to improve its flavor, and finally packaged.

Kurkure Production Line is developed and produced on the basis of the previous equipment, which is superior to the previous production process and better able to meet the needs of food processing plants, saving costs while bringing higher economic benefits, the main advantages of which are as follows.

Advantages of Kurkure Production Line:

1、The whole line is highly automated, easy to operate, and saves manpower.

2、Visualized automatic temperature control system makes temperature control more intuitive and parameters more accurate.

3、The line covers a small area, is flexible configuration, easy to operate, and highly adaptable.

4、All machines are made of food-grade stainless steel, reasonable design, and reliable quality.

5、Adopt imported frequency conversion or electromagnetic control system, smooth operation, superior performance, and long service life.

The above is the introduction of Kurkure Production Line's processing process and its characteristics. Through the above content, I believe you have a specific understanding of the production of Kurkure snacks. The Kurkure snack machine is flexible in configuration, easy to operate, and highly adaptable. It has many advantages and is well received by the industry.