Industrial Microwave Silica Drying Technology

Introduction Of Microwave Silica Drying Machine:

Microwave silica drying machine is a specialized equipment designed to dry silica gel using microwave radiation. Silica gel is a widely used adsorbent that is capable of absorbing moisture and other impurities from the air, making it a popular choice for various industrial and commercial applications.The machine works by utilizing microwaves to generate high-frequency electromagnetic waves that rapidly heat and evaporate water molecules in the material. This allows for faster drying times and a more uniform drying process, which helps to maintain the integrity and quality of the silica gel.

Parameter Of Microwave Silica Drying Machine:

| Equipment Model | LY-100 Industrial Microwave Drying Machine For Silica |

| Rated Input Apparent Power | Customization |

| Height Of Conveyor | 600-1000mm |

| Inlet And Outlet Height | 40-100mm |

| Width Of Conveyor Belt | 750±100mm(Custom-Made) |

| Microwave Leakage Standard | ISO≤5mw/Cm² |

| Operating Frequency | 2450±50Hmz |

| Transmission Speed | 0~10m/Min(Adjustable Frequency) |

Feature Of Microwave Silica Drying Machine:

1. Uniform Drying: The machine ensures uniform drying of silica gel since microwaves penetrate the gel thoroughly, thus drying every part.

2.Automated Operation: The machine is automated and can be easily operated by setting the time and temperature for drying, and the machine does the rest.

3.Consistent Performance: Microwave silica drying machines provide consistent results since the drying process is controlled using a timer and temperature regulator.

4. Cost-Effective: Compared to traditional drying techniques, microwave silica drying machines offer a cost-effective option since they consume less energy and require minimal labor, leading to lower operational costs.

5. Compact Design: The machines are designed to save on space and can be easily integrated into existing production lines without causing significant disruptions.

6.Stainless Steel construction: The machine is built with stainless steel construction, making it durable, easy to clean, and resistant to rust and corrosion.

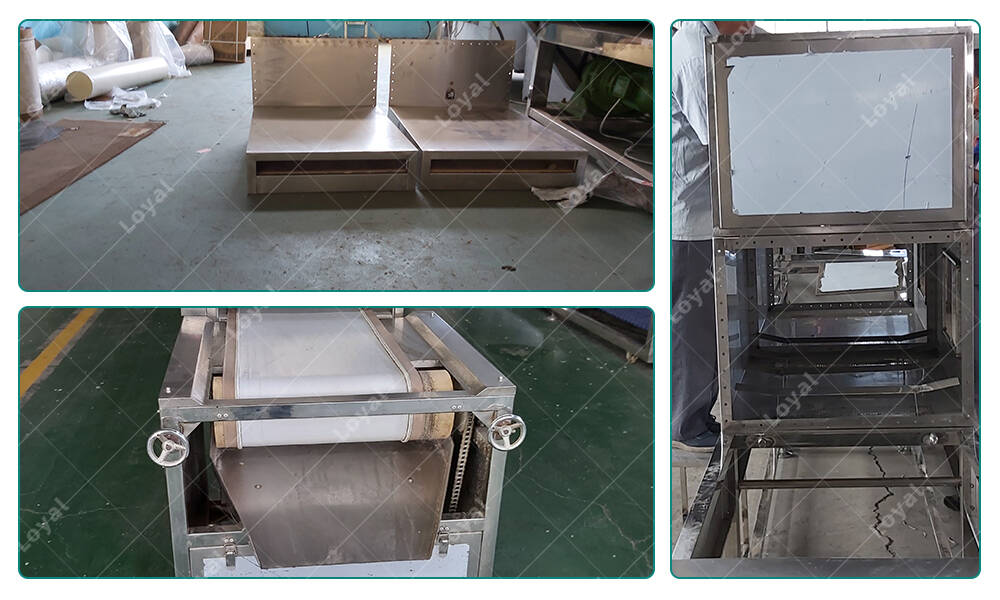

Details Display Of Microwave Silica Drying Machine:

Applications Of Microwave Silica Drying Machine:

1 | Pharmaceutical Industry | In the pharmaceutical industry, silica gel is extensively used as an adsorbent for purification purposes. The microwave silica drying machine is used to dry silica gel in a rapid and efficient manner. |

2 | Chemical Industry | The chemical industry uses silica gel for chromatography, drying solvents, and other applications. The microwave silica drying machine is used to dry silica gel efficiently. |

3 | Food Industry | Silica gel is widely used in the food industry as a desiccant to prevent food spoilage due to moisture. The microwave silica drying machine can dry silica gel quickly and efficiently. |

4 | Cosmetics Industry | Silica gel is used in the cosmetics industry to help regulate moisture content in products such as powders, creams, and lotions. The microwave silica drying machine can dry silica gel efficiently and maintain its adsorbing properties. |

Advantages Of Loyal Microwave Drying And Sterilization Equipment:

1.Adopt Food Grade Stainless Steel, Nice Appearance, Easy To Clean.

2.Microwave Can Penetrate Through The Materials So That The Inside And Outside Are Heated At The Same Time, Short Processing Time,Evenly Drying And Thorough Terilization. No Extra Heat Loss, High Heat Efficiency, Saving Energy.

3.Thermal Effect And Non-Thermal Effect Work Together, Achieving Ideal Sterilization Effect At Low Temperature And Short Time, The Vegetable Can Keep Their Nutrition Components To The Maximum.

4.Adopt Non-Contact Infrared Temperature Measurement Technology, High Precision, Automatic Control.