How To Produce Biscuits With Loyal's Equipment

1.Description Of Biscuit Process Line

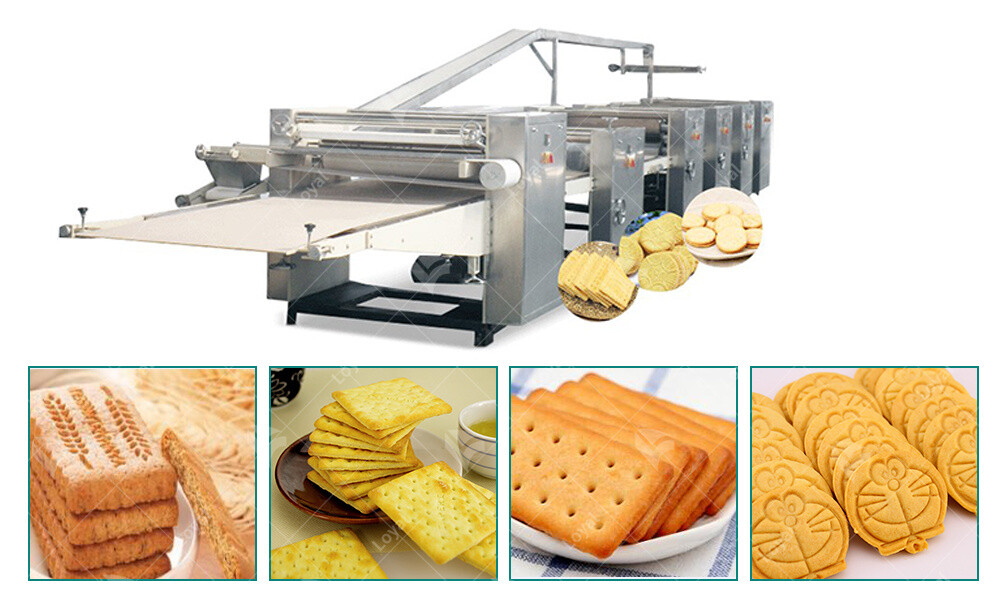

This automatic forming machine is applied for biscuit/ crispy cake production. This machine is easy operation with the adjustable cutting knife. It can roll the dough into different shapes and weights. The pressing roller is specially designed to allow the knife evenly cut and easy for replacement. Besides, this machine can be equipped with tunnel oven or hot air rotary oven for mass production.

Trough toughening,crisp type forming machine ,can produce hard biscuit,cake buscuit,walnut cake biscuits,thickness can be adjusted ,and mechanical operation,frequency control of motor speed,adjust freely according to different products,and has advanced functions such as leakage power and alarm automatically.Automatic temperature adjustment freely according to different products,baking,automatic transmission,automatic fuel injection,automatic cooling,etc.

Trough toughening,crisp type forming machine ,can produce hard biscuit,cake buscuit,walnut cake biscuits,thickness can be adjusted ,and mechanical operation,frequency control of motor speed,adjust freely according to different products,and has advanced functions such as leakage power and alarm automatically.Automatic temperature adjustment freely according to different products,baking,automatic transmission,automatic fuel injection,automatic cooling,etc.

2.Flow Chart Of Biscuit Process Line

Flour Mixing---Soft Biscuit Forming---Biscuit Baking---Oil Spraying---Biscuit Stacking ---Cooling and Sterilization ---Biscuit Packing

3.Details Of Biscuit Process Line

| Model | LY-65 | LY-70 | LY-85 | LY-90 |

| Power(Kw) | 10 | 15 | 22 | 26 |

| Dimension (mm) | 7000*1000*1500 | 8000*1200*1500 | 10000*1600*1500 | 11000*1800*1500 |

| machine weight (kg) | 3000 | 4000 | 7000 | 9000 |

| Capacity(kg/h) | 100-200kg/h | 300-500kg/h | 500-800kg/h | 600-900 |

4.Advantages Of Biscuit Process Line

| 1. Easy to operate |

| 2. Save energy and labor |

| 3. No noise, no pollution |

| 4. Fully automatic and improving production efficiency. |

| 5. Continuous production, no material loss and save cost. |

5.Service Of Biscuit Process Line

| Pre-Sale Service | After Sale Service: |

| 1.Related machines's technical parameter will be supplied to customer. | 1.Allocation chart as the buyer's request will be supplied. |

| 2.According to customer's factory size, factory layout can be provided in advance. | 2.Operation manual will be supplied after shipment. |

| 3. According to customer's material cost, general formulation can be prepared well. | 3.One year warrantee, life time maintenance with cost price. |

| 4.Special machine can be supplied as customer's request. | 4.Free easy broken spare parts will be sent with container . |

| 5.Professional Advice about Market, machines, processing , materials, packing can be supplied | 5.First installation can be done by engineer |

| 6. Suggesting professional ship agent or helping book ship as customer request. | 6.Training workers in customer's factory. |

6.Application Of Biscuit Process Line

Cookie Making Machine is novel in design, compact in structure, and highly automated. From feeding to calendering, molding, waste recycling, drying, oil injection, and cooling, it is fully automatic and one-time carry out. Our company provides customers with hundreds of molds and dozens of process formulas. By changing the molds and process formulas, it can produce various high-end biscuits popular in the market, such as butter biscuits, sandwich biscuits, ultra-thin biscuits, milk biscuits, soda biscuits, Animal biscuits, multi-dimensional biscuits, vegetable biscuits, etc.