How To Choose The Best nutrition bar making machine: 2025 Buyer’s Guide

Understanding Nutrition Bars

Nutrition bars come in various forms, including:

Protein Bars – High in protein, often used by athletes and fitness enthusiasts.

Energy Bars – Designed for quick energy boosts, containing carbohydrates and healthy fats.

Meal Replacement Bars – Balanced with macronutrients to substitute a full meal.

Fiber Bars – Rich in dietary fiber to support digestion.

Organic/Gluten-Free Bars – Catering to health-conscious consumers with dietary restrictions.

Each type requires a slightly different production approach, but the core manufacturing process remains similar.

Introduction for Nutrition Bar Industry

In today's fast-paced world, consumers are increasingly seeking convenient, nutritious, and delicious snack options. Nutrition bar, a high-protein, energy-boosting nutrition bar, has gained immense popularity among health-conscious individuals, athletes, and busy professionals. To meet the growing demand, investing in a state-of-the-art Nutrition bar production line is essential for manufacturers aiming to deliver high-quality, consistent, and scalable snack solutions.

The Composition for Nutrition Bar Making Machines

Sugar Boiled Pot

Function: Used for cooking syrup.

Features: electromagnetic heating, adjustable gear, high efficiency.

Oil Sugar Electromagnetic Insulation Pot

Function: used for storage and delivery of syrup and oil to the sugar pot

Electromagnetic Sugar Cooker

Function: Used for cooking syrup

Features: Electromagnetic heating, adjustable gear, high efficiency, automatic tipping bucket.

Weighing Feeder

Function: Used for quantitative weighing and conveying of granular materials

Features: Accurate quantitative, automatic feeding.

Temperature Control Mixer

Function: Full mixing of materials, can be reversed,

External heating and heat preservation, temperature control, the inner wall of the pot and the stirring claws are sprayed with Teflon, anti-sticking.

Hoist

Function: Used for conveying the mixed material to the hopper of the forming machine.

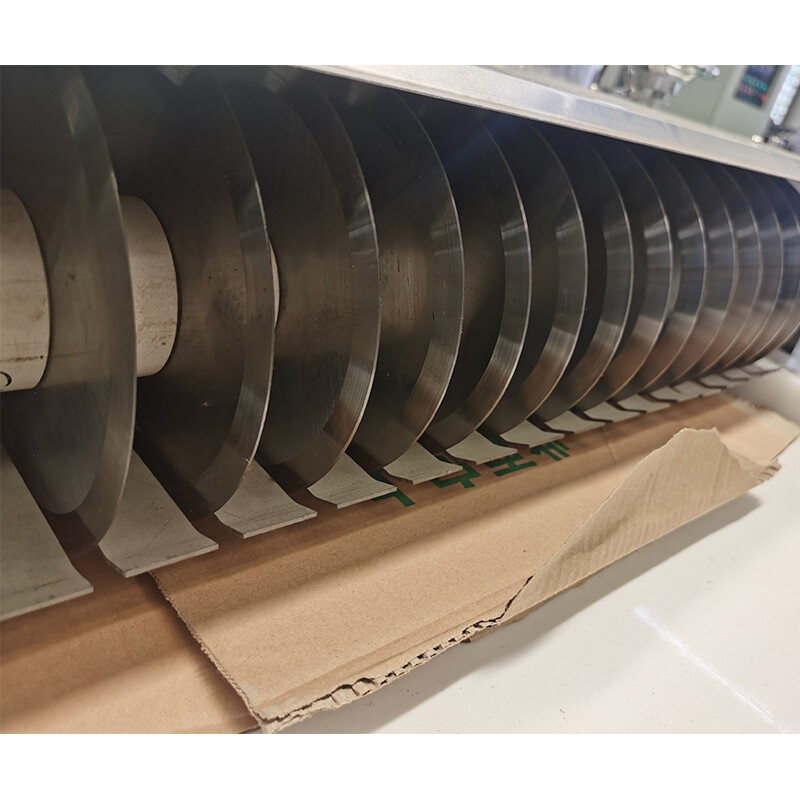

Automatic Cereals Bar Cutting Machine

Function: Used for leveling, cooling, cutting and forming of products.

Features:

1. Microcomputer PLC control, adjustable speed, adjustable height, error can be corrected

2. The horizontal knife is equipped with an air pump auxiliary pressure device, which has good cutting effect and neat knife edge.

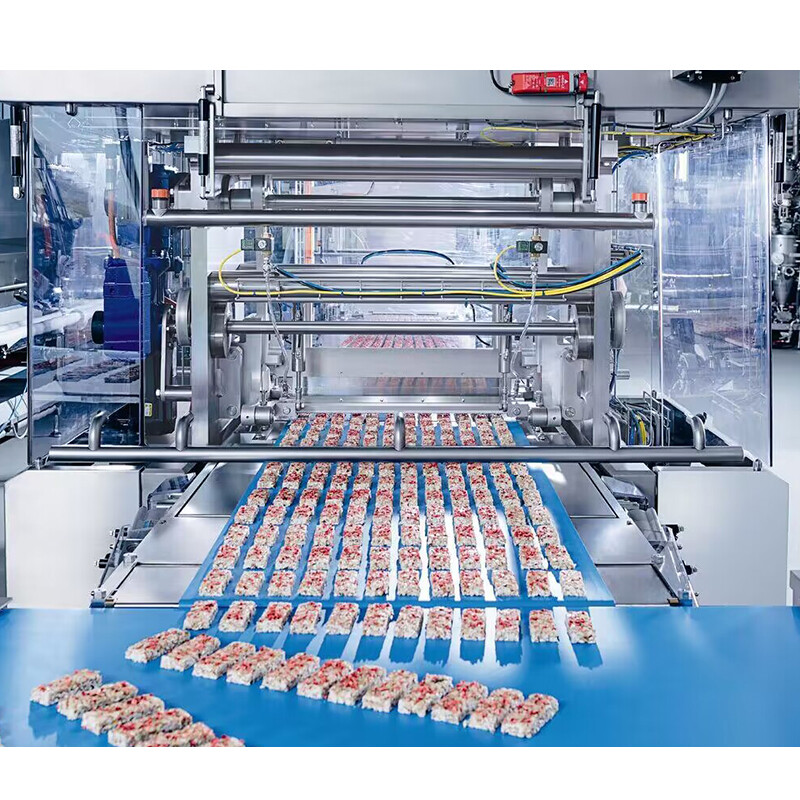

Nutrition Bar Making Machines Processing Overview

Raw Material Handling – Ingredients are stored in hygienic silos and dispensed via automated systems.

Mixing & Cooking – Ingredients are blended and cooked to form a homogenous mass.

Forming & Cutting – The mixture is shaped, cooled, and cut into bars.

Coating (Optional) – Bars are enrobed with flavors or coatings.

Packaging – Finished bars are sealed for freshness and shelf-life extension.

Benefits of an Automated Nutrition Bar Production Line

In the competitive health food industry, efficiency, consistency, and scalability are crucial for manufacturers. A fully automated nutrition bar production line offers numerous advantages over traditional semi-automated or manual processes. Below, we explore the key benefits of automation in nutrition bar manufacturing.

1. Increased Production Efficiency & Higher Output

Faster Processing : Automated systems can mix, extrude, mold, coat, cut, and package bars at a much higher speed than manual labor.

24/7 Operation : With minimal human intervention, automated lines can run continuously, maximizing output.

Reduced Downtime : Advanced sensors and predictive maintenance minimize unexpected stoppages.

Example : A fully automated line can produce 10,000–50,000 bars per hour , whereas manual or semi-automated lines may only achieve 2,000–5,000 bars per hour .

2. Superior Consistency & Product Quality

Precision in Mixing & Forming : Automated blenders and extruders ensure uniform texture and ingredient distribution.

Exact Portion Control : Automated cutting and weighing systems guarantee each bar meets weight specifications (±1% accuracy).

Consistent Coating & Enrobing : Robotic enrobing machines apply coatings evenly, improving appearance and taste.

Impact : Reduces customer complaints due to inconsistent texture, size, or flavor .

3. Enhanced Food Safety & Hygiene

Minimal Human Contact : Reduces contamination risks from handling.

Automated Cleaning Systems (CIP – Clean-in-Place) : Ensures equipment is sanitized without disassembly.

Real-Time Quality Monitoring : X-ray detectors, metal detectors, and vision systems identify foreign objects or defects.

Regulatory Benefit : Easier compliance with FDA, HACCP, and GMP standards.

4. Labor Cost Savings & Reduced Human Error

Lower Workforce Dependency : Fewer operators are needed, reducing long-term labor costs.

Elimination of Manual Errors : No inconsistencies in mixing, shaping, or packaging.

Training Simplification : Operators only need to monitor machines rather than perform complex manual tasks.

Cost Example : A fully automated line may require only 2–5 operators per shift , while a semi-automated line might need 10–15 workers .

5. Flexibility for Customization & Product Variety

Quick Changeover Systems : Automated lines can switch between different recipes (e.g., protein bars, keto bars, vegan bars) with minimal downtime.

Custom Shapes & Sizes : Adjustable molds and cutters allow for unique bar designs.

Multi-Layer & Filled Bars : Advanced extrusion and depositing systems enable layered or center-filled bars.

Market Advantage : Faster adaptation to trends like plant-based, gluten-free, or low-sugar bars .

6. Waste Reduction & Sustainability Benefits

Precision Ingredient Dispensing : Minimizes overuse of costly ingredients (e.g., nuts, chocolate).

Scrap Reuse Systems : Some automated lines can recycle excess mixture back into production.

Eco-Friendly Packaging Integration : Automated flow wrappers can handle biodegradable films.

Cost Savings : Reduces raw material waste by 5–15% compared to manual processes.

7.Data-Driven Optimization & Smart Manufacturing

IoT & AI Integration | Real-time monitoring of temperature, humidity, and machine performance. |

Predictive Analytics | Detects potential equipment failures before they occur. |

Traceability & Batch Tracking | Barcode/RFID systems ensure full supply chain transparency. |

Industry 4.0 Impact | Enables smart factories with self-optimizing production lines. |

Quality Control & Food Safety Standards

To produce safe and high-quality nutrition bars, manufacturers must adhere to:

HACCP (Hazard Analysis Critical Control Points) – Identifies and controls potential hazards.

GMP (Good Manufacturing Practices) – Ensures hygienic production conditions.

FDA/EFSA Compliance – Meets regional food safety regulations.

Allergen Control – Prevents cross-contamination (e.g., nuts, gluten).

Shelf-Life Testing – Ensures bars remain fresh under specified conditions.

Challenges in Nutrition Bar Production

Ingredient Variability

Natural ingredients (e.g., nuts, fruits) can vary in moisture content, affecting texture.

Stickiness & Handling

Some mixtures are too sticky, requiring specialized equipment.

Shelf-Life Management

Moisture migration can cause bars to harden or become soggy over time.

Cost Control

Premium ingredients (e.g., organic, non-GMO) increase production costs.

The future development trends of fully - automatic nutrition bar production lines are as follows:

Higher Automation and Intelligence

Widespread Application of IoT Technology: The production line will be equipped with more sensors to collect real - time data on production metrics such as temperature, humidity, and ingredient levels. This data will be transmitted to a centralized system for analysis through IoT technology, enabling operators to remotely monitor and control the production process and make timely adjustments to ensure stable production.

Deep Integration of AI and Machine Learning: AI algorithms will be used to analyze production data to predict equipment failures and maintenance needs, enabling proactive maintenance to minimize downtime. Meanwhile, machine learning technology will be able to optimize the production process based on historical data, such as adjusting ingredient ratios and processing parameters to improve product quality and production efficiency.

Greater Customization and Flexibility

Product Customization: In response to the increasingly diverse and personalized consumer demands, the production line will be capable of quickly switching between different product formulas, shapes, and packaging designs. For example, through programmable control systems, operators can easily adjust the mixing times, temperatures, and ingredient ratios of the equipment to produce various types of nutrition bars, including high - protein, low - sugar, organic, and allergen - free ones.

Production Flexibility: The production line will be designed to be more modular and scalable, allowing manufacturers to easily expand or adjust production capacity according to market demand. Additionally, it will be able to handle small - batch production tasks efficiently, providing support for the R & D and production of new products.

Enhanced Energy Efficiency and Sustainability

Application of Energy - Saving Technologies: The production line will increasingly adopt energy - saving technologies such as variable frequency drives, which adjust energy usage based on production demands, and heat recovery systems that recycle energy from processes like drying. This will help reduce energy consumption and production costs while also improving the environmental friendliness of production.

Sustainable Packaging: With the growing emphasis on environmental protection, there will be a trend towards using more sustainable packaging materials on the production line, such as biodegradable and recyclable materials. At the same time, the packaging process will be optimized to reduce material waste and improve packaging efficiency.

Stringent Quality Control and Traceability

Advanced Quality Detection Technologies: The production line will be equipped with more advanced quality detection equipment and technologies, such as online sensors for detecting the quality of raw materials and finished products, and vision inspection systems for checking the appearance and packaging of products. These technologies will help detect quality problems in a timely manner and improve product quality and consistency.

Establishment of a Traceability System: A complete traceability system will be established for the entire production process, from raw materials to finished products. Through barcode, RFID, and other technologies, the source, processing, and distribution information of each batch of products can be tracked and traced, enabling quick recall and treatment of problem products and ensuring food safety.

Improved Product Innovation and Development Capabilities

Continuous Introduction of New Ingredients: As consumers' demands for health - promoting ingredients increase, production lines will need to be able to handle a wider variety of new ingredients, such as high - protein inclusions, superfoods, and functional mushrooms. This requires continuous innovation and improvement in the mixing, blending, and processing equipment to ensure the even distribution and full functionality of these ingredients in the product.

R & D of New Product Forms and Flavors: In addition to traditional bar shapes, there will be more innovative product forms, such as bite - sized, filled, or layered nutrition bars, to meet consumers' diverse needs. Meanwhile, new flavors will continue to be developed, such as those that combine sweet and savory tastes or feature unique regional flavors, to enhance the palatability and market competitiveness of the products.

Why Invest in the Nutrition Bar Making Machines?

The global nutrition bar market is projected to exceed $7.5 billion by 2027 , driven by rising health awareness and demand for on-the-go nutrition. By adopting an automated nutrition bar production process, manufacturers can:

✔ Capture a growing market with high-margin, functional snacks.

✔ Differentiate their brand with innovative flavors and premium packaging.

✔ Reduce production costs through automation and waste minimization.

✔ Comply with food safety regulations (ISO, HACCP, FDA standards).

Conclusion

The Nutrition Bar production line represents the future of healthy snack manufacturing, combining speed, precision, and versatility to meet consumer demands. Whether you're an established food producer or a startup entering the nutrition bar market, investing in this advanced production system ensures a competitive advantage, superior product quality, and long-term profitability.

For manufacturers ready to capitalize on the booming health snack market, now is the time to upgrade to an automated nutrition bar production line and deliver nutritious, delicious bars to consumers worldwide.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/