Fully Automatic Pet Dog Biscuit Manufacturing Machine: High-Efficiency Energy Saving

Introduction to Pet Dog Biscuit Manufacturing Machines

The pet food production industry has witnessed significant growth over the past decade, driven by an increasing awareness of pet nutrition and the humanization of pet care. Pet owners now prioritize high-quality, nutritious, and safe food options for their furry companions, and the pet food market has responded with a diverse range of products, including premium pet biscuits specifically designed for dogs.

In response to these trends, the Pet Dog Biscuit Manufacturing Machine has become an essential piece of equipment for companies aiming to meet rising demands for quality pet treats. This advanced machinery enables manufacturers to produce dog biscuits efficiently and consistently, ensuring the right balance of nutrition and taste. According to Dr. Lisa Freeman, a renowned expert in animal nutrition, "The demand for specialized pet food equipment underscores the commitment to food safety and nutritional standards, both essential in today's pet care industry."

Importance of High-efficiency, Energy-saving Equipment

The Pet Dog Biscuit Manufacturing Machine is engineered to cater to the growing need for high-quality and efficient pet food production. In today's competitive pet food market, manufacturers are increasingly prioritizing machinery that combines high-efficiency and energy-saving features, both to meet operational demands and to contribute to environmental sustainability. High-efficiency machinery reduces production costs, minimizes waste, and optimizes energy usage, which are crucial factors for large-scale pet biscuit production.

Overview of the Pet Dog Biscuit Manufacturing Machine

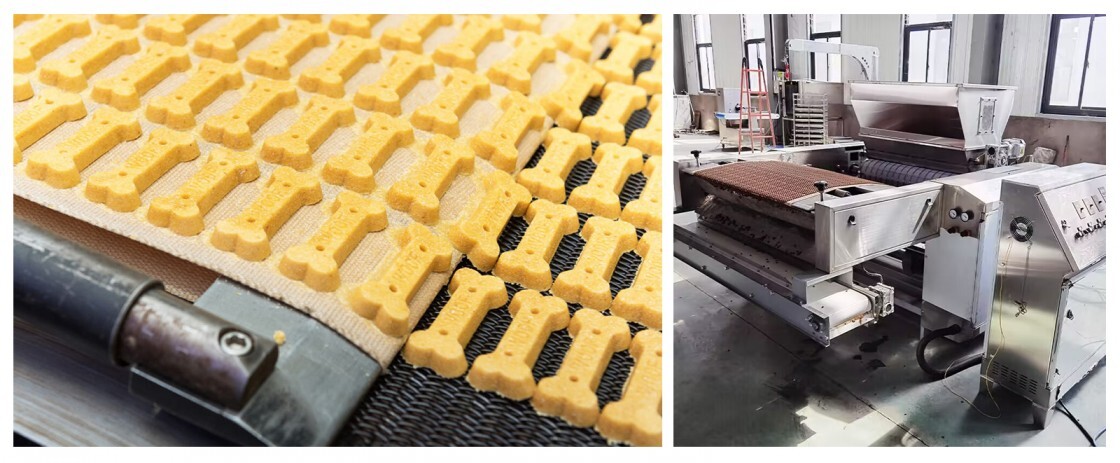

This fully automated equipment is designed to handle each stage of the biscuit-making process, from mixing ingredients to forming, baking, and cooling, all while maintaining precise quality control. The Pet Dog Biscuit Manufacturing Machine is built with a durable stainless-steel structure that ensures hygiene, durability, and easy maintenance. Its stainless-steel components also comply with food-grade standards, preventing contamination and extending the lifespan of the machine.

Machine Description and Production Capabilities

Detailed breakdown of each machine function

The Pet Dog Biscuit Manufacturing Machine is meticulously designed to support each phase of the production process with advanced technology, allowing for high-quality output at large volumes. Its multifunctional design integrates several key processes, including ingredient mixing, dough forming, biscuit shaping, baking, and cooling — all in one streamlined system. This automation significantly reduces manual labor and enhances production speed without compromising product consistency or quality.

Customizable settings for biscuit shape, size, and texture

One of the standout features of this machine is its customizable settings. Manufacturers can adjust parameters for biscuit shape, size, and texture to meet specific market demands and create unique product offerings. The machine supports various biscuit shapes — from traditional round or bone-shaped treats to more creative, novelty designs. By simply adjusting the settings, manufacturers can quickly produce a wide range of biscuit varieties, providing flexibility and innovation in product development.

High-capacity output for large-scale production

With its high-capacity output, the Pet Dog Biscuit Manufacturing Machine is ideal for large-scale production, enabling companies to fulfill bulk orders while maintaining efficiency. Capable of handling substantial batches in a short period, this machine supports high-volume production demands, making it a valuable asset for large pet food manufacturers aiming to expand their distribution capabilities.

Benefits of Fully Automatic Pet Dog Biscuit Manufacturing Machines

1.Labor and cost savings with automation

2.Consistent product quality and minimal waste

3.Improved energy efficiency in production processes

4.Meeting diverse pet dietary needs and preferences

Maintenance and Operational Guidelines

Routine maintenance procedures for prolonged machine life

Proper maintenance of the Pet Dog Biscuit Manufacturing Machine is essential for ensuring optimal performance and prolonging its operational lifespan. Routine maintenance procedures, such as regular cleaning, lubrication, and inspection of moving parts, can prevent wear and tear and keep the machine running efficiently. It's recommended that operators establish a maintenance schedule, including weekly checks and periodic part replacements, to minimize downtime and ensure consistent production quality.

Troubleshooting common issues for uninterrupted production

For uninterrupted production, operators should be trained in troubleshooting common issues. Potential problems, such as dough blockages, temperature inconsistencies, or conveyor malfunctions, can be addressed with quick solutions provided in the machine’s operational manual. Following these guidelines allows for more seamless production, reduced repair costs, and enhanced overall productivity.

Conclusion and Future Outlook

Summary of the Pet Dog Biscuit Manufacturing Machine advantages

The Pet Dog Biscuit Manufacturing Machine offers a multitude of benefits for pet food manufacturers, from high-efficiency production and energy-saving capabilities to versatile settings and a high-capacity output. These features make it an invaluable tool for companies aiming to produce quality dog biscuits at scale, meeting the increasing market demands for nutritious, appealing pet treats.

Future trends in pet food production technology

Looking ahead, the pet food production industry is expected to continue embracing advanced technology to further improve product quality, safety, and efficiency. Innovations in automation and sustainable machinery, such as the high-efficiency, energy-saving features found in this machine, align with global trends toward greener manufacturing. As manufacturers adopt more eco-friendly practices, these machines will help drive sustainable growth by reducing resource consumption and minimizing environmental impact.

In an industry that values both nutrition and environmental responsibility, machines like the Pet Dog Biscuit Manufacturing Machine are essential. By providing a reliable, efficient production solution, they support manufacturers in meeting today’s standards and preparing for future demands, positioning them at the forefront of the evolving pet food market.

FAQs: Common Questions about the Pet Dog Biscuit Manufacturing Machine

Q1: What types of biscuits can the Pet Dog Biscuit Manufacturing Machine produce?A: The Pet Dog Biscuit Manufacturing Machine is highly versatile, allowing users to produce a wide variety of dog biscuits in different shapes, sizes, and textures. It can be customized to create traditional bone-shaped biscuits, circular treats, or even unique designs tailored to brand requirements.

Q2: How energy-efficient is this machine?A: This machine is specifically designed with energy-saving features, optimizing power consumption at each stage of production. With high-efficiency heating and automated controls, it minimizes energy waste, helping manufacturers reduce costs while supporting sustainable operations.

Q3: Is the machine easy to operate and maintain?A: Yes, the Pet Dog Biscuit Manufacturing Machine is equipped with a user-friendly interface and automated control panel, making it easy for operators of all experience levels to manage. Routine maintenance, like cleaning and lubrication, is simple and helps keep the machine in top condition, ensuring longevity and minimal downtime.

Q4: What is the production capacity of the machine?A: This machine supports high-capacity output, making it ideal for large-scale manufacturing. Production volume can be adjusted based on specific requirements, allowing flexibility for both small and large batch production.

Q5: Are there safety features integrated into the machine?A: Absolutely. Safety is a priority in the Pet Dog Biscuit Manufacturing Machine, which includes emergency stop functions, automatic shutdowns in case of malfunctions, and protective shields. These features ensure safe operations for all staff members involved in the production process.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website: https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website: https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/