Fully Automatic Microwave Sterilization Equipment: Revolutionizing the Condiment Industry

Fully Automatic Microwave Sterilization Equipment: Revolutionizing the Condiment Industry

Introduction

Our company leverages cutting-edge technologies from Ispecc and Püschner to develop a state-of-the-art microwave sterilization technique. By drawing inspiration from the advanced methodologies employed by Ispecc and Püschner, we have successfully integrated their innovative approaches into our manufacturing process. This collaborative effort ensures that our microwave sterilization technology meets the highest industry standards, providing an effective and efficient solution for eliminating harmful microorganisms. Through continuous refinement and adaptation of these proven techniques, our company remains at the forefront of technological advancements in the field, delivering products that prioritize both safety and quality.

The Significance of Microwave Sterilization

Microwave sterilization emerges as a key player in enhancing food safety, especially within the condiment sector. The unique qualities of microwave technology, such as rapid heating and uniform distribution, contribute to more effective sterilization processes. This segment explores the pivotal role played by microwave sterilization in elevating food safety standards, emphasizing its specific advantages in the context of condiments.

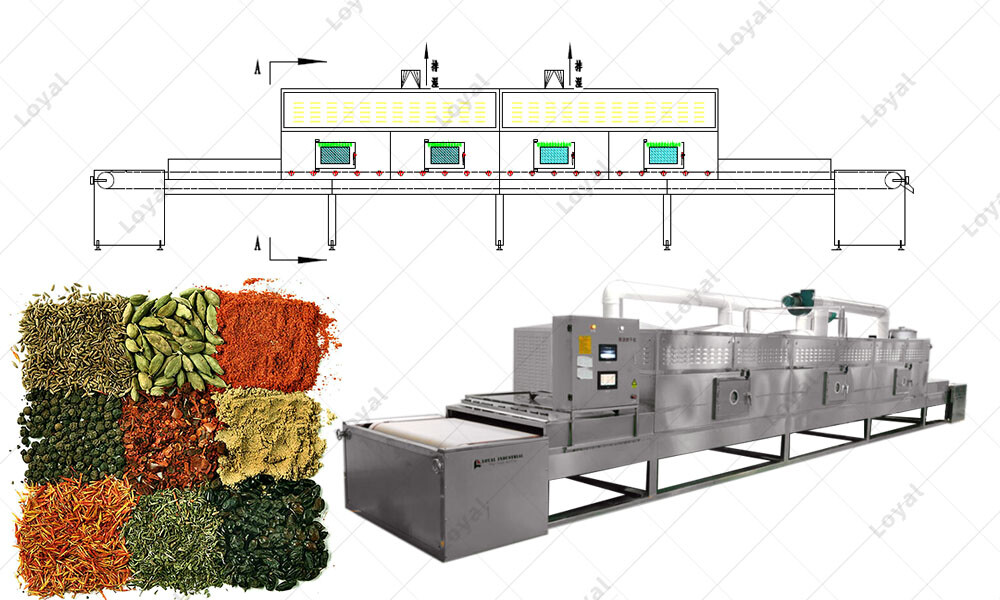

Technological Advancements in Fully Automatic Equipment

A deep dive into the technological advancements of fully automatic microwave sterilization equipment reveals a host of features designed to enhance efficiency and precision in the condiment industry. With a focus on automation, this section highlights how the technology seamlessly integrates into existing production processes, offering a new level of control and quality assurance.

Operational Efficiency and Energy Conservation

Efficiency gains and energy conservation are paramount considerations in the condiment industry. Here, we discuss how fully automatic microwave sterilization equipment not only streamlines operations but also champions energy-saving initiatives. Insights into the environmental impact of this technology underscore its commitment to sustainable and responsible manufacturing practices.

Real-world Applications in the Condiment Industry

To substantiate the theoretical advantages, this section delves into real-world applications and success stories of fully automatic microwave sterilization in condiment production. By examining practical examples, we illustrate the positive outcomes and tangible benefits experienced by businesses that have embraced this transformative technology.

Challenges and Solutions

In the journey of adopting fully automatic microwave sterilization equipment within the condiment industry, businesses may encounter specific challenges. Understanding and proactively addressing these challenges are crucial for a seamless integration process.

Developing thorough training programs that encompass both theoretical knowledge and hands-on experience is essential. Collaboration with equipment manufacturers or industry experts can facilitate tailored training sessions, ensuring the workforce is proficient in utilizing the new technology.

Integrating fully automatic microwave sterilization into existing production lines may require adjustments to established workflows. Ensuring a smooth transition without disrupting overall operations can be a complex task.

Experience with Fully Automatic Microwave Sterilization:

"I've witnessed a paradigm shift in the condiment industry with the integration of fully automatic microwave sterilization. The precise control over the sterilization process ensures that the essence of each ingredient is retained. As a chef, having access to such technology not only enhances the safety of the condiments I use but also opens up possibilities for more nuanced and creative flavor profiles."

Future Trends and Innovations

Exploring the horizon of possibilities, this section looks ahead to potential future trends in microwave sterilization technology for condiments. Anticipating innovations that could further revolutionize the industry, we provide a glimpse into the exciting advancements on the horizon.

Case Studies and Testimonials

As we delve into the real-world applications of fully automatic microwave sterilization equipment in the condiment industry, the experiences of businesses and industry experts offer invaluable insights into the transformative impact of this technology.

Case Study : "Global Flavor Innovations"

Global Flavor Innovations, a multinational condiment producer, sought to elevate their commitment to sustainability and efficiency. Traditional sterilization methods were resource-intensive and posed environmental challenges.

Embracing fully automatic microwave sterilization technology, Global Flavor Innovations redefined their production processes. The precise control and energy-saving features aligned with their sustainability goals.

The technology's energy-saving aspects contributed to a significant reduction in overall energy consumption.Global Flavor Innovations positioned itself as an environmentally conscious brand, resonating with eco-conscious consumers.

Regulatory Compliance and Safety Standards

Compliance with regulatory requirements is crucial in the condiment industry. This segment underscores the importance of adhering to standards and regulations, while also highlighting how fully automatic microwave sterilization ensures compliance and maintains safety standards.

Conclusion

In conclusion, this section summarizes the revolutionary impact of fully automatic microwave sterilization equipment on the condiment industry. Encouraging businesses to embrace this innovative technology for enhanced safety, efficiency, and overall quality, the conclusion emphasizes the transformative nature of this technology in shaping the future of condiment production.

Frequently Asked Questions about The Application of Microwave Sterilization in Condiment Industry

How does microwave sterilization differ from traditional methods in the condiment industry?

Microwave sterilization offers a faster and more uniform heating process compared to traditional methods. It enables efficient pathogen elimination while preserving the quality and flavors of condiments.

Can fully automatic microwave sterilization equipment be integrated into existing production lines?

Absolutely. One of the key features of fully automatic equipment is its seamless integration into existing production processes. This ensures minimal disruption while maximizing efficiency.

What are the energy-saving aspects of fully automatic microwave sterilization?

Fully automatic microwave sterilization equipment is designed for energy efficiency. Its precise control mechanisms and rapid processing contribute to reduced energy consumption, aligning with sustainability goals in the condiment industry.

Are there specific condiments that benefit more from microwave sterilization?

Microwave sterilization is versatile and suitable for a wide range of condiments. From sauces to dressings and beyond, its adaptability allows for effective and uniform sterilization across various products.

How does microwave sterilization contribute to regulatory compliance and safety standards?

Microwave sterilization ensures compliance by meeting stringent safety standards. The automated process is designed to consistently deliver results that align with regulatory requirements in the condiment industry.

Are there notable examples of successful implementation in the condiment industry?

Yes, several condiment manufacturers have experienced success with fully automatic microwave sterilization. Case studies highlight improved safety, enhanced quality, and increased production efficiency.

What challenges might businesses face when adopting this technology, and how can they be addressed?

Challenges could include initial investment and process adjustments. Solutions involve thorough training for personnel, strategic implementation plans, and a focus on the long-term benefits of enhanced condiment production.