Broasted Crispy Chicken Frymaster Industrial Deep Fryer Machine

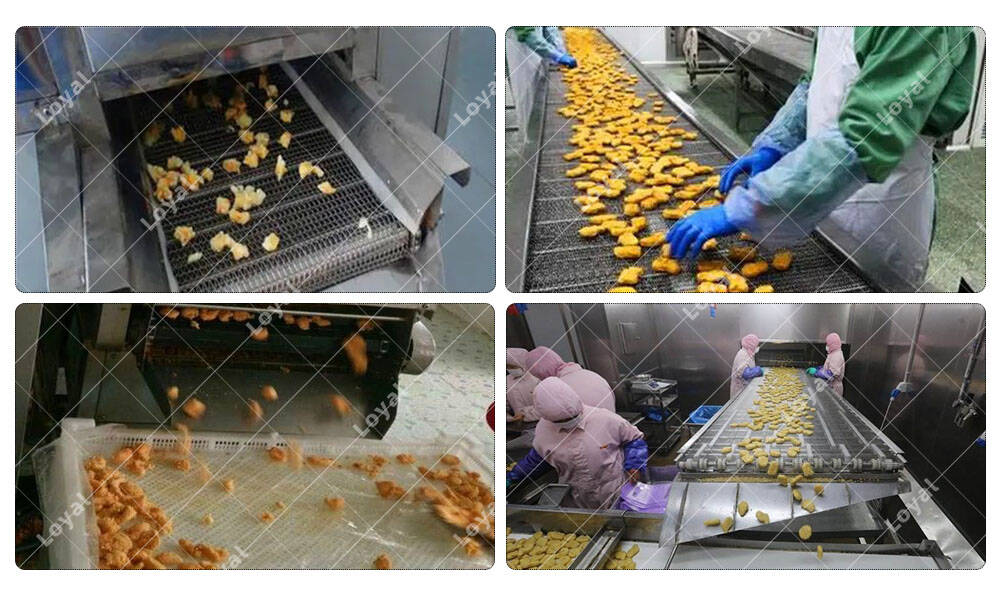

Deep fryer machine can be applied to the preparation of a variety of products, with a rich variety of products, such as rice crackers, cat ears, chicken, fish, potatoes, etc. As industrial continuous fryer manufacturer, the loyal commercial deep frying machine have been exported to more than 116 countries and regions, promoting the development of the local economy. The entire broasted crispy chicken frymaster industrial deep fryer machine of is made of food-grade stainless steel, and the craftsmanship is very high. The fried food is not only delicious, but also safe and harmless. Industrial continuous frying Machine is the first choice for your business development. Because automatic deep fryer machine not only has the above advantages, can be produced on a single machine, so it is very easy to operate for novices. And commercial deep frying machine is also very friendly to customers with low start-up capital, which can reduce the investment of start-up capital.

Broasted Crispy Chicken Frymaster Industrial Deep Fryer Machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 10-25 working days. |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Voltage | 380V/50HZ Three Phase, 440v, 415v, etc |

| MOQ | 1 set/Deep Fryer Machine |

| Keywords | Deep Fryer Machine |

| Heating Source | Gas, Electric, Diesel |

| Certification | CE,ISO9001,SGS,BV |

| Applicable Industries | Food equipment plant, Snacks Food Factory etc. |

| Machine material | Stainless Steel 201 304 |

Broasted Crispy Chicken Frymaster Industrial Deep Fryer Machine Detail Introduction :

Our deep fryer machine can be applied to the preparation of a variety of products, with a rich variety of products, such as rice crackers, cat ears, chicken, fish, potatoes, etc. The entire fried food deep frying machine of our industrial continuous fryers is made of food-grade stainless steel, and the craftsmanship is very high. The fried food is not only delicious, but also safe and harmless. You can make products on a single machine. Industrial continuous frying Machine is the first choice for your business development. Because automatic deep fryer machine not only has the above advantages, can be produced on a single machine, so it is very easy to operate for novices. And commercial deep frying machine is also very friendly to customers with low start-up capital, which can reduce the investment of start-up capital.

Characteristics Of Chicken Fryer Equipment

The Characteristics Of Boasted Crispy Chicken Industrial Deep Fryer Machine | |

1 | Deep fryer machine has a high degree of automation and can work continuously. The body itself has a small footprint and is easy to operate. |

2 | Our industrial fryer is very oil-saving and has a self-filtering system. |

3 | It has a one-year warranty service and perfect after-sales service. |

4 | The applicable product types are rich and diverse, and the finished products are both beautiful and delicious. |

5 | The product is healthy, high-quality, and uses a special process to keep all layers of edible oil pure. |

6 | The mesh belt is made of stainless steel. There are stainless steel conveyor chains on both sides of the fryer. |

7 | Place an aluminum silicate insulation material between the inside and outside of the fryer to reduce heating loss. |

8 | Stainless steel plates are used inside the fryer. And conduct a water pressure test to ensure that there is no leakage in the frying machine body. |

Process Flow of Deep Fryer Machine

Prepare the ingredients-check the fryer and wiring-turn on the fryer-proceed to frying-clean the fryer

Before using the continuous namkeen fryer, prepare the required raw materials, and then put the prepared raw materials into the fryer for frying. Remember to clean the fryer in time after the frying is completed.

The continuous fryer machine can be heated by electricity, oil, gas and coal. In order to prevent excessive oxidation of the oil, our fryer heats the central part of the oil layer and controls the temperature of the upper and lower oil layers. The continuous fryer has a double-layer belt, which can evenly fry the product. The product is fried between the two layers of steel wire belts so that it cannot run freely. The stainless steel ribbon can convey products at an adjustable speed. In order to extend the life of the oil, our continuous fryer can automatically filter the oil and control the temperature of the oil during the continuous food fryer.

Parameter of Continuous Fryer Machine

Technical Parameter Of The Full Automatic Deep Fryer Machine | ||||

Heating Method: Electric/Gas lFrying Temperature Range: 80-300 Degree C lTemperature Precision ±1℃ lFrying Time control Range :30seconds-150seconds Frequency Adjustable. lOil Volume 260 Liter lBelt type: Staircase Mesh Belt | ||||

Frying Equipment Mode | Heating Power | Heating Temperature | Output | Size (L*W*H) |

LY-L(electric fryer) | 97kw/h | ~250℃ | 300kg/h | 3000x1200x2100mm |

LY-G (Gas/Diesel) | 6-20.5m³/h(Gas) 7-15kg/h(Diesel) | ~250℃ | 300kg/h | 3000x1200x2100mm |

LY-L-2 (electric fryer) | 122kw/h | ~250℃ | 400-500kg/h | 4000x1300x2200mm |

LY-G-2 (Gas/Diesel) | 35m³/h(Gas), 8-41kg/h (Diesel) | ~250℃ | 400-500kg/h | 4000x1300x2200mm

|

ABB Motor Used In The Processing Of Continuous Commercial Mesh Belt Deep Fryer Machine

Abb Motor Of Automatic Deep Orchid Beans Frying Machine | |

Package Level /1 Units | 0 Carton |

Product Name | 3-Phase Squirrel Cage Motor |

Product Net Weight | 5.9 Kg |

Product Type | 3Aa2__M3Aa_Ie2_Aa |

Scip | 27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (Fi) |

Selling Unit Of Measure | Piece |

Standards | Iec 60034-1 |

Starting Of Motor | Direct Online |

Advantages of Automatic Deep Fryer Machine With Temperature Control

The Advantages of the Boasted Crispy Chicken Industrial Deep Fryer Machine | ||

The frying machine uses the principle of different proportions of oil, water, and animal oil to sink all the residues produced during the working process into the water, and the animal fat sinks into the lower layer of vegetable oil. It fundamentally solves the problem of residues, animal fats, and repeated frying in the traditional frying machine that acidify and carbonize the frying oil and deteriorate and produce carcinogens. | ||

1 | Improve quality and ensure health | The special process keeps residues and animal fats out of the working layer. The heating in the middle can effectively control the convection of the upper and lower oil layers to ensure the purity of various oil layers. |

2 | Save frying oil, which is conducive to environmental protection | The oil-water mixing technology continuously produces a small amount of steam from the water under the oil layer. The central heating process can be adjusted at will according to the needs, and the electric control device can control the upper and lower temperature, which can effectively alleviate the oxidation degree of the fried oil, thereby prolonging the life of the fried oil. |

3 | The oil does not smell, one machine is multi-purpose | The process uses limit control, zone temperature control, and scientific use of the proportion of vegetable oil and animal oil. The animal oil leached from the fried food naturally sinks into the lower layer of the vegetable oil, so that the middle and upper working oil is always pure.

|

What Kind Of The Automatic Doritos Production Line Doritos Tortilla Chips Making Machine Has Been Loyal Sold In 2021 ?

Customer Case Of The Fried Snacks Automatic Continuous Frying Machine In 2021 | |

1 | 200kg/h Industrial Chicken Nuggets Continuous Peanut Deep Fryer Machine For Sale Thailand Agent |

2 | Small Capacity Automatic Conveyor Belt Continuousfryer 2D Snack Pellet Frying Machine For Sale Sudan |

3 | 500kg/h Conveyor Continuous Deep Fryer Machine Potato Chips Fryer Machine For Sale Burkina Faso Factory Plant |

4 | 800kg/h Continuous Fryer Fried Dough Snacks Frying Machine For Sale Australian Supplier |

Repurchase Case Customer With Continuous Mesh Belt Frying Machine Technology In 2021 | |

1 | 100kg/h Continuous Fryer Frying Machine Tortilla Chips Deep Fries Machines For Sale America |

2 | 300kg/h Automatic Banana Chips Continuous Fryer Frying Cooking Machine Sale To Bolivia Technical Engineering Processing |

3 | 500kg/h Plc Control Industrial Continuous Belt Fried Snacks Deep Frying Equipment Conveyor Fryer Machine For Sale Dominica |

4 | Large Capacity Continuous Fryer Frying Machine Cassava Chips Deep Fries Machines For Sale In Senegal |

5 | 250kg/h Snacks 3D Pellet Chips Continuous Belt Deep Frying Equipment Price In Nigeria Manufacturer |

Transaction Case Customer Of Continuous Deep Frying Machine Machine In 2021 | |

1 | 450-500kg/h Pellet Chips Continuous Automatic Gas Chin Chin Belt Frying Oil Fryer Machine For Sale Thailand |

2 | Uzbekistan Automatic Continuous Chips Pellet Snack Deep Fryer Machine For Sale Uzbekistan (Tashkent) |

3 | 300kg/H Chicken Chop Tempura Shrimp Squid Rings Continuous Fryer Frying Machine For Sale Myanmar |

4 | Continuous Automatic Nuts Belt Frying Oil Fryer Machine For Sale With New Technology To Vietnam Agent |

5 | Automatic Snacks Food Potato Chips Fryer Continuous Frying Machine Peanut Frying Machine For Sale Zimbabwe Supplier |

6 | 600kg/h Continuous Automatic Gas Pig Skin Belt Fryer Machine For Sale Turkmenistan |

Customer Case Of Fried Chips Industrial Continuous Frying Machine At Discount Prices In 2021 | |

1 | 500kg/h Electric Fried Chips Deep Air Continuous Fryer Machine For Sale Mozambique |

2 | 1000 Kg/h Pellet Snacks Machine Continuous Deep Fryer Machine For Sale Austria |

3 | Automatic Fish Continuous Deep Fryer Machines For Sale Moldova Manufacturing Process |

4 | 250kg/h Full Automatic Nuggets Burger Continuous Deep Fryer Machines For Sale Ukraine |

5 | Auto Crispy Onion Fryer And Frying Machine With Continuous Filtration System For Sale Singapore Agent |