Automatic Frozen French Fries Machine

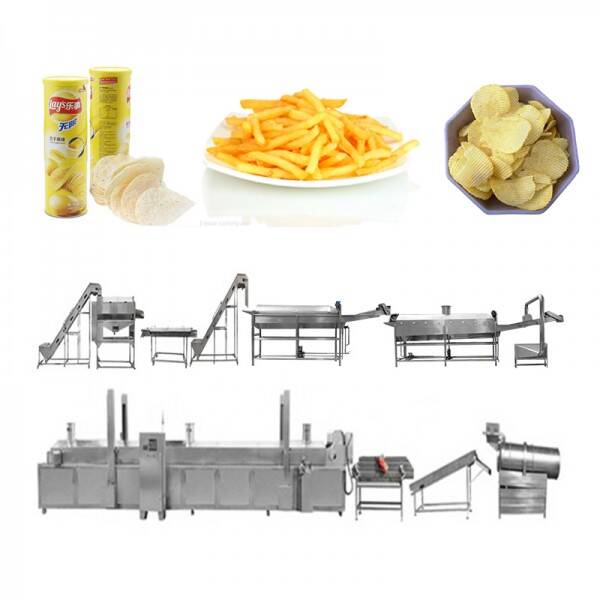

Automatic Frozen French Fries Machine project using fresh potatoes as raw materials, the whole process of washing, peeling, slicing, washing, de-watering, frying, seasoning and other steps to make delicious potato chips and Frozen french fries for sale. French fries not only retains the unique delicious flavor of potatoes, but also has the characteristics of rich nutrition, delicious taste and convenience, and is favored by consumers. The potato chips processing line has the advantages of low energy consumption, multiple functions, small size, high profit , and convenient use and maintenance. The potato chips line is easy to be operated, powerful and investment saving. As One of the largest fried potato French Fries potato chips making machine manufacturer, the loyal fully automatic potato chips line have been exported to more than 116 countries and regions, promoting the development of the local economy.

Automatic Frozen French Fries Machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Payment Terms | T/T,L/C,D/P |

| Delivery Detail | 3days--7days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Voltage | 380V/50HZ Three Phase, 440v, 415v, etc |

| MOQ | 1 set/Automatic Frozen French Fries Machine |

| Keywords | Full Automatic Frozen French Fries Machine |

| Application fields | Vegetable processing plant, Snack food factory |

| Capacity | 100-1000kg/h |

| Certification | CE,ISO9001,BV |

| Warranty | 1 Year |

| After-sales Service Provided | Field maintenance and repair service |

Automatic Frozen French Fries Machine Detail Introduction :

How Are Mcdonald's French Fries Processed?

French fries are fresh potatoes that are washed, peeled, sliced, fried, seasoned and frozen. French fries not only retains the unique delicious flavor of potatoes, but also has the characteristics of rich nutrition, delicious taste and convenience, and is favored by consumers. Chas the characteristics of high automation, simple operation and energy saving. Frozen fries last longer than potato chips, which is why some snack bars and restaurants (such as cafeterias, McDonald's, and KFC) cook fries for sale. French fries maker processes high-quality frozen fries that meet hygienic standards.

How Are French Fries Made In a Factory?

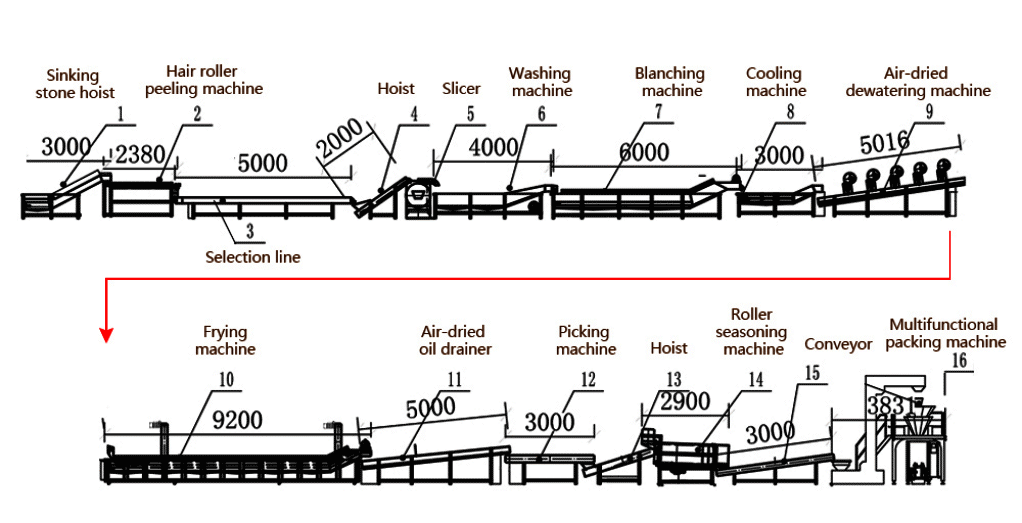

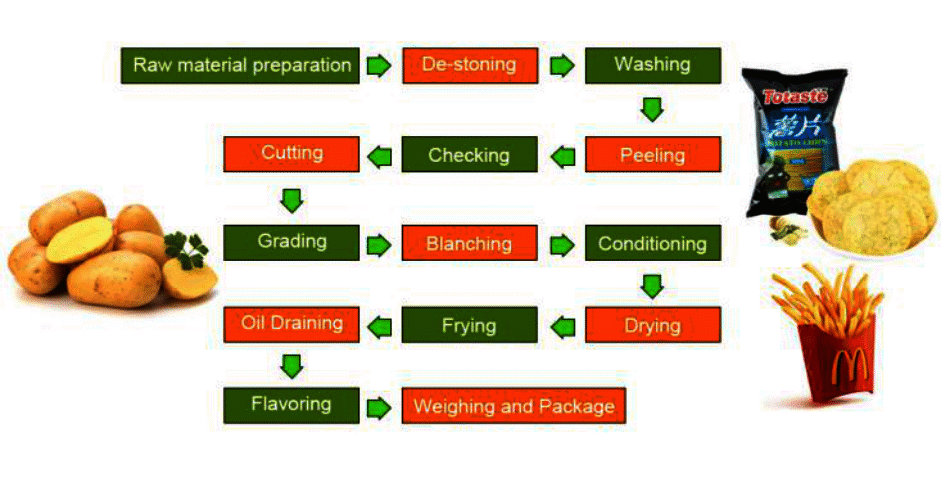

Peeling -- Cutting -- Rinsing -- Blanching -- Shaken And Drained -- Frying -- Deoiling-- Seasoning -- Freezing -- Weighing and Packing.Flow Chart of Automatic Frozen Fren

What Is The Process Of Making French Fries?

Equipment List Of Full Automatic French Fries Making Machine | ||

| No. | Name | Functions Of French Fries Making Machine |

| 1 | Washing And Peeling Machine | Washing and peeling machine is used to peeling potatoes with hard brush and emery brush; Uneven and corrugated brush can peel the potatoes completely. |

| 2 | French Fries Cutting Machine | French fries cutting machine is used to cut potato into sticks, french fries quality depends on fries length and shape, so cutting machine is very important. |

| 3 | Rinsing Machine | Rinsing machine is used to washing potato starch and protect potato from oxidation, keep its original color. |

| 4 | Blanching Machine | Blanching machine is used to deactivate the activity of the oxidase, take off the starch, separate out the reducing sugar, also after blanching,it will get inner soft taste of french fries. |

| 5 | Vibrating Machine | Vibrating machine is used to remove water.Also have many holes at the end of machine to leak out small part and waste part potato. |

| 6 | Continuous Frying Machine | Continuous frying machine is used to unified fry sticks in short time. |

| 7 | Vibrating De-Oil Machine | Vibrating de-oil machine is used to de-oil with the vibrating. |

| 8 | Freezing Machine | Freezing machine is used to quick freezing the french fries in short time, fries center temperature at -18 ºC, Can the maximum keep the original flavor and product quality. |

| 9 | Automatic Weighing And Packing Machine | Automatic weighing and packing machine is used to pack the french fries automatically, including bucket Elevator. |

How Much Fries Maker Machine Cost?

Technical Parameters Of Commercial Fried French Fries Maker Machine | ||||

| Model | Output | Size (L*W*H) | Main Power | French Fries Machine Price |

| LY-100 | 120-150kg/h | 25000*1500*2100mm | 22KW | USD 25,000.00-38,000.00 |

| LY--200 | 200-250kg/h | 28000x1600x2200mm | 35KW | USD 38,000.00-45,000.00 |

| LY-300 | 400-500kg/h | 28000x1600x2200mm | 47KW | USD 47,000.00-60,000.00 |

| The French Fries Potato Chips Production Line Price Is The Promote Price In 2022. Updated Price Pls Check With Our Fried Snacks Food Machine Line Team. | ||||

Is French Fries a Good Business?

Features Of Automatic Potato Fries Making Machine Manufacturing Process | |

| 1 | Fully automatic to produce frozen French fries from fresh potatoes. |

| 2 | All machines are made of stainless steel 304. |

| 3 | Electricity power requirement is 380V/50Hz/three-phase. |

| 4 | Various production, 300kg/h, 500kg/h and 1000 kg/h for customers. |

| 5 | High efficiency and energy saving, with good quality. |

| 6 | Comparative price and high rate of profitable return. |

Specifications Of French Fries Machine For Business Motor

Specifications Of Industrial Fried French Fries Machine For Business Motor | |

| Attribute | Value |

| Power Rating | 0.18 KW |

| Efficiency Class | IE2 |

| AC Motor Type | Induction |

| Supply Voltage | 415 V ac |

| Phase | 3 |

| Output Speed | 1380 rpm @ 380 V |

| Number of Poles | 4 |

| Mounting Type | Foot |

| Rotation | Reversible |

| Maximum Output Torque | 1.25 Nm |

Introduction Of Fries Cutter Machine

Fries Cutter Machine can cut the vegetables and fruit to oblong and square. Potato cutting machine for french fries adopt combination cutting tool, one time forming, with regular shape, tangent plane smooth. Potato cutting machine for french fries uses a rotating dial to feed the material on the feed chute, then inclined distribution knife, curved sharp edge for cutting. With good quality, high efficiency, easy operation and low energy consumption.

2021 Customer Order Automatic French Fries Chips Making Machine Form

Customer Case Of Muti-Function Fried French Fries Making Machine With Discount Price In 2021 | |

1 | 100-150/H Automatic French Fries Maker Potato Chips Processing Making Machine For Sale Senegal Factory |

2 | 150kg Potato French Fries Making Machine Weave Potato Chips Production Line For Sale Nigeria |

3 | 500Kg/H Electric Automatic French Fries Processing Line For Sale Burkina Faso Manufacturing Processing |

4 | 150Kg/H Gas Automatic Potato Chips Sticks Processing Making Machine For Sale Botswana Agent |

5 | 100-150kg/h Industrial Potato Finger Snack Food Making Machine For Sale Philippines Customer Factory Plant |

6 | 800kg/h Potato Chips French Fries Making Production Line Machine For Sale Pakistan With Discount Price For Sale |

7 | 1000 Kg/H Automatic Fried French Fries Production Line For Sale Mozambique |

Customer Case Of The Potato Chips French Fries Production Line With The Farm Setting In 2021 | |

1 | 200-250kg/h Fresh French Fries Flakes Stick Fully Automatic Sweet Potato Chips Machine For Sale Thailand Agent |

2 | 100kg/h Semi-Automatic Potato Chips Production Line Frozen French Fries Making Machine For Sale (Tashkent) Agent |

3 | 500kg/H Fully Automatic Large Potato Chips Machine For Sale America Manufacturers |

4 | 1000kg/H Automatic Potato Chips French Fries Production Line For Brazil Suppliers |

Transaction Case Of The Commercial Potato Chips Processing Line With High Quality Manufacturer In 2021 | |

1 | 200-250kg/h Commercial Potato Chips Fryer Making Frying Snack Food Machine Manufacturers Food Production Line For Sale Austrian Agent |

2 | 100-150kg/h Capacity Potato Chips Crisps Snacks Chips Food Machine For Sale To Moldova Factory Plant |

3 | 100-150kg/h Frozen French Fries Frying Making Machine Processing Equipment For Sale Ukraine |

4 | 500kg/h Frying Snacks Processing Machine Crispy Potato Chips Processing Machine For Sale Singapore Factory Plant |

5 | 400kg/h Automatic Frozen French Fries Making Machine Potato Chips Production Line For Sale Puerto Rico |

High Quality Trader Customer Case Of The Industrial Potato French Fries Machine Price In 2021 | |

1 | 100kg/h Industrial Potato Chips French Fries Food Maker Machine Production Line For Sale Bolivia Agent |

2 | 800kg/H Industrial Fried Potato Snacks Chips Food Processing Equipment Cost Price For Sale Dominica |

3 | 300kg/h Potato Sticks Food Maker Machine Production Line In Senegal Manufacturers |

4 | 100-150Kg/H Industrial Potato Chip Making Machine Price In Nigeria |

5 | 200-250kg/h French Fries Production Line Factory For Sale Cote d'Ivoire |

6 | 500kg/h Snack Frozen French Fries Production Line Fresh Potato Chips Fryer Making Frying Food Processing Machine Cost For Sale Cameroon |

7 | Professional Manufacturer Potato Chips Making Equipment French Fries Machine For Sale South Africa Food Suppliers |

Automatic Frozen French Fries Machine