200KG/H Wheat Flour Snack Making Machine, Sticks Snack Fried Wheat Dough Snack Machine

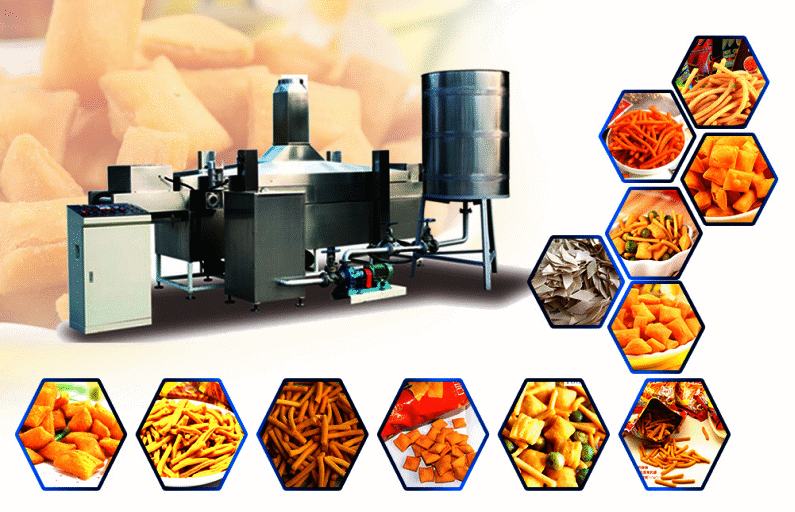

Loyal industrial fried wheat dough snacks machine all types of wheat flour snacks making machine engineering projects with great prices and high quality. We have exported to America, UK, Brazil, Thailand, Vietnam, and other 116 countries and regions. Fried dough snack machine can take wheat flour ,corn flour starch and others as raw materials, to make the fried snack chips for sales. 200KG/H Wheat Flour Snack Making Machine, Sticks Snack Fried Wheat Dough Snack Machine processing dough with wheat flour, and then shaping and cutting the skin into forming products. After being pressed by serious stainless rollers, the dough food snacks can be separately cut into pillow or stick shapes and expanded by frying. Fried wheat flour based snack process line is reasonably designed and conveniently operated, with the fermentation and drying function. No need a dryer, simple process, less investment. Fried wheat flour snacks making machine is the best choice for middle-sized manufacturing Factory. Fried dough snack production line can make different kinds of fried snacks based on changing die molds and recipe, such as stick snacks, bugles chips, Doritos chips, pellet chips and so on.

200KG/H Wheat Flour Snack Making Machine, Sticks Snack Fried Wheat Dough Snack Machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Model Number | LY65, LY70, LY 85 |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Keywords | Wheat Flour Snacks Production Line Fried Dough Food Machine |

| MOQ | 1 set/ Wheat Flour Snacks Production Line |

| Voltage | 380V/50HZ Three Phase, 440v, 415v, etc |

| Certification | CE BV ISO 9001 |

| Material | Stainless Steel 304 |

| Trial Demonstration | Welcome You To Visit Us At Any Time For Machinery Demonstration |

| Automation | Fully Automatic |

| After-sales Service Provided | Engineers available to service machinery overseas |

200KG/H Wheat Flour Snack Making Machine, Sticks Snack Fried Wheat Dough Snack Machine Detail Introduction :

PRODUCT DETAIL OF 200KG/H WHEAT FLOUR SNACK MAKING MACHINE, STICKS SNACK FRIED WHEAT DOUGH SNACK MACHINE

Fried dough snack production line is for processing dough with wheat flour, and then shaping and cutting the skin into forming products. After being pressed by serious stainless rollers, they can be separately cut into pillow or stick shapes and expanded by frying. After that, they can be flavor-mixed and dried till they become appetizing and snack foodstuff. Fried wheat flour based snack process line is reasonably designed and conveniently operated, with the fermentation and drying function.

The shapes of product are changed and they taste crispy and delicious after fried and flavored in the processing of the Fried dough snack production line. No need a dryer, simple process, less investment.It is the best choice for middle-sized companies.

MAIN FEATURES OF LOYAL’S 200KG/H WHEAT FLOUR SNACK MAKING MACHINE, STICKS SNACK FRIED WHEAT DOUGH SNACK MACHINE:

Main features of the Fired Dough Sticks Snacks Extruder Making Machine | |

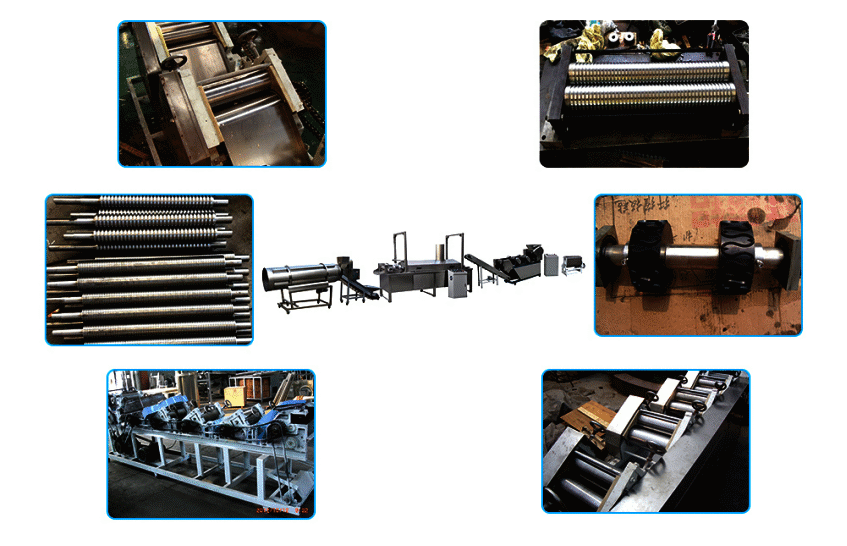

| 1 | Simple Structure In Linear Type, Easy In Installation And Maintain. |

| 2 | Adopting Advanced World Famous Brand Components In Pneumatic Parts, Electric Parts And Operation Parts. |

| 3 | High Pressure Double Crank To Control The Die Opening And Closing. |

| 4 | Running In a High Automation And Intellectualization, No Pollution. |

| 5 | Apply a Linker To Connect With The Air Conveyor, Which Can Directly Inline With Filling Machine. |

HOW TO PROCESSIONING THE DOUGH SNACK CHIPS?

THE FLOW CHART OF FRIED DOUGH SNACK PRODUCTION LINE:

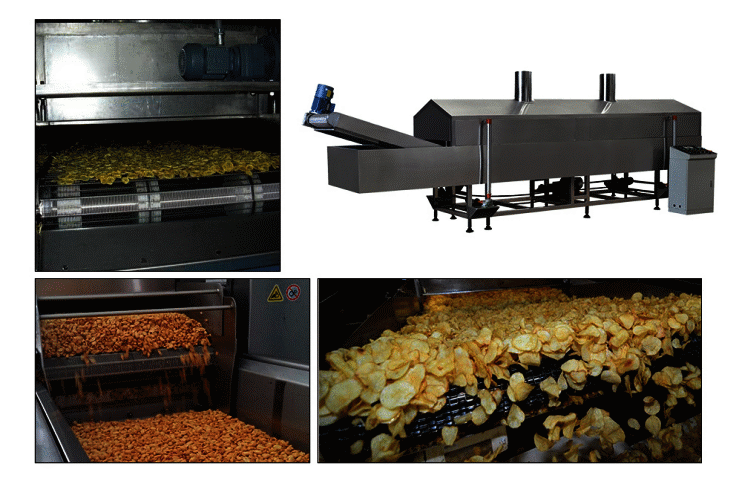

Flour Mixer→Conveyor→Sheeter→Cooling Conveyor→Vibrating Feeder→ Continuous Fryer→De-Oiling & Cooling Conveyor→Flavoring Line

1. Brand new sheet with 6 press rollers, make the sheet with uniform thickness and smooth surface.

2. New multi-layer stable temperature warmer, get a good fermentation status before frying.

3. Newly designed cutting blade with adjustable speed to make the length of the final product can be adjusted.

4. Newly designed conveyor, no leakage and non-sticking.

5. Automatic oil supply and temperature control system for fryer to guarantee the stable temperature variations.

6. The whole line is easy to operate.

PRODUCT PARAMETERS OF 200KG/H WHEAT FLOUR SNACK MAKING MACHINE, STICKS SNACK FRIED WHEAT DOUGH SNACK MACHINE:

Technical Parameter Of Full Automatic Fried Dough Snack Production Line | |||||

Model | Installed capacity | Power | Output capacity | Size (L*W*H) | Price($) For Reference |

LY65 | 88KW | 65KW | 150-200kg/h | 18000x2000x4000mm | 16,500-18,900 |

LY70 | 126KW | 82KW | 200-250kg/h | 22000x2000x4000mm | 22,500-26,500 |

LY70L | 126KW | 82KW | 250-350kg/h | 26000x2000x4000mm | 32,500-38,500 |

ABB Motor Usd In The Fried Dough Food Making Processing Line

ABB Motor Application In the Fried Snacks Chips Processing Line | ||

| 1 | Package Level 1 Units | 0 carton |

| 2 | Product Name | 3-Phase squirrel cage motor |

| 3 | Product Net Weight of Automatic Potato Chips Making Plant | 5.9 kg |

| 4 | Product Type | 3AA2__M3AA_IE2_AA |

| 5 | SCIP of Potato Chips Processing Plant | 27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (FI) |

| 6 | Selling Unit of Measure | piece |

| 7 | Standards of Potato Chips Automatic Plant Cost | IEC 60034-1 |

| 8 | Starting of Motor | Direct Online |

WHAT PRODUCTS CAN LOYAL’S 200KG/H WHEAT FLOUR SNACK MAKING MACHINE?

The full automatic fried dough snack production line line can make different kinds fried snacks using corn flour, rice flour, wheat flour, starch, potato flour and other grain flour etc. as raw materials based on shaping the sheet into different shapes. The finished products are very crispy, delicious and less oil.

THE ADVANTAGES OF 200KG/H WHEAT FLOUR SNACK MAKING MACHINE, STICKS SNACK FRIED WHEAT DOUGH SNACK MACHINE

The Advantages Of The Full Automatic Fried Dough Snack Making Processing Frying Machine System | |

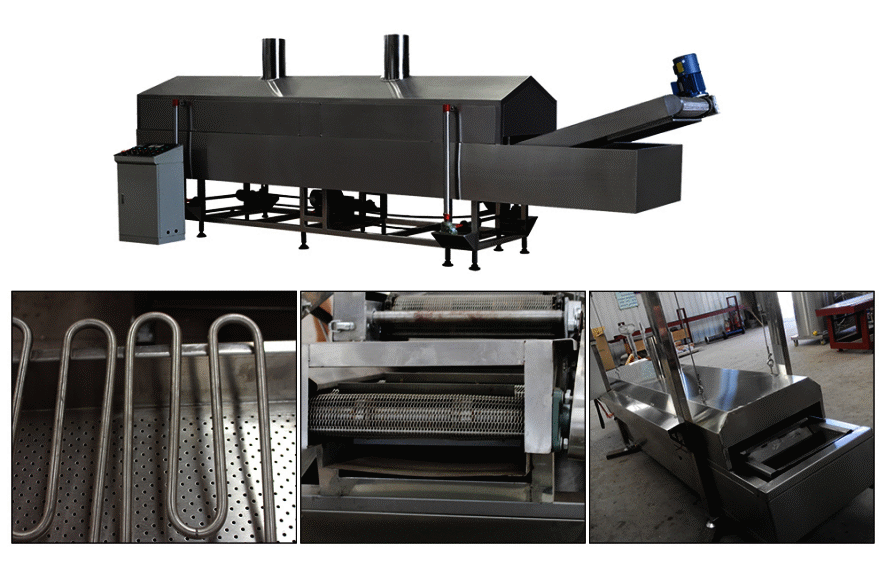

1 | Electric heating fryer is used the most common one of frying machine, uses the electric heating, cleaning, security, health and green environmental protection. |

2 | Oil temperature all achieve full automatic control, the range is from normal temperature to 230ºC, but can not exceed 230ºC. |

3 | The frying machine uses pure oil design, oil less, total time of oil flow improve, saving production costs. |

4 | Frying machine is designed with dynamic diesel filtration systems, when the frying machine works it can be automatically filtered. |

5 | Frying time can be controlled and adjusted the speed willfully according to the process. |

6 | Frying machine with double_layer net belt design, is used for a variety of fried foods. |

7 | Frying machine is designed with move net rack systems, net rack as a whole can be lifted for easy cleaning. |

MORE DETAILS OF STICKS SNACK FRIED WHEAT DOUGH SNACK MACHINE

Which Market Of The Fried Wheat Dough Snack Machine Has Been Loyal Sold In 2021 ?

Customer Case Of Muti-Function Wheat Flour Snack Making Machine With Discount Price In 2021 | |

1 | 100-150/H Fried Dough Snack Production Line For Sale Senegal Suppliers Factory |

2 | 300kg/h Fried Sticks Snack Food Processing Making Machine For Sale Nigeria |

3 | 100-150Kg/H Double Screw Fried Wheat Flour Rice Chip Extruder Machine For Sale Burkina Faso Manufacturing Processing |

4 | 150Kg/H Stainless Steel Corn Flour Dough Production Line For Sale Botswana Agent |

5 | 100-150kg/h Crispy Chip Fried Wheat Flour Snack Food Making Machine For Sale Philippines Customer Factory Plant |

6 | 800kg/h Industrial Full Automatic Fried Wheat Flour Pillow Stick Snack Process Line For Sale Pakistan With Discount Price For Sale |

7 | 200-250 Kg/H Fried Wheat Flour Snack Making Machine For Sale Mozambique |

Transaction Case Of The Commercial Sticks Snack Fried Chips Making Machine With High Quality Manufacturer In 2021 | |

1 | 200-250kg/h Fried Wheat Flour Snacks Food Bugles Chips Machine Food Production Line For Sale Austrian Agent |

2 | Ly65 100-150kg/h Extruded Wheat Flour Pellet 3D Snacks Machine For Sale To Moldova Factory Plant |

3 | 100-150kg/h Bugles Making Extruder Machine Processing Equipment For Sale Ukraine |

4 | Ly-65 Fried Wheat Mimi Strip Snacks Production Line For Sale Singapore Factory Plant |

5 | 400kg/h Fried Flour Snacks Chips Machinery Extruder Production Line For Sale Puerto Rico |

High Quality Trader Customer Case Of The Industrial Fried Wheat Dough Snack Machine Equipment Processing Line Price In 2021 | |

1 | 100kg/h Fried Wheat Flour Snacks Making Machine For Sale Bolivia Agent |

2 | 800kg/H Industrial Fried Wheat Flour Fried Bugles Chips Processing Line Cost Price For Sale Dominica |

3 | 300kg/h Full Automatic Fried Dough Foods Machine Fried Wheat Snack Machinery In Senegal Manufacturers |

4 | 100-150Kg/H Fried Snacks Making Machine Crispy Chips Making Processing Machinery Price In Nigeria |

5 | 200-250kg/h Double Screw Newest Fried Wheat Dough Snack Machine Factory For Sale Cote d'Ivoire |

6 | Ly-65 Fried Dough Twist Hemp Flowers Snacks Making Extrusion Machinery Extruder Cost For Sale Cameroon |

7 | Ly-70 Bugles Chips Making Machines Fried Wheat Flour/Dough Snacks Food Processing Line For Sale South Africa Pet Food Suppliers |

OUR SERVICE

The Services Of Loyal Industrial Company | |

High-quality after-sales service | Engineer services for overseas machinery services |

1. The distribution map requested by the buyer will be provided. | 1. Provide free consultation service before, during and after sale. |

COMPANY INTRODUCTION

Shandong Loyal Industrial Co., Ltd. is located in the beautiful city (Spring City) in Shandong Province China. Our company is a professional food machine manufacture with many years' experience.

Our company offers variety of products which can meet your variety demands. We always try our best to satisfy potential needs of our customers. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with irresistible force.

With the development of our company, our products have been exported to more than eighty countries, such as the United States, Poland, Canada, Mexico, Brazil and so on.

In the unremitting efforts of all staff, we hope that our products and services can help you achieve personal career aim, we would like to use our sincerely and enthusiasm to become your long-term partner and intimate friend since our first touching.

Welcome to visit our factory!

Loyal brand was famous well-known at global and domestic market, and it is sold to more than 50 countries and regions, with ISO system, SGS certificate, 10 CE certificates, and 25 patents on Technology Patent, since then, we keep forward on the quality control, new technology developing and the better customer service.

OUR HONOR