Low Electricity Fish Meal Fish Feed Production Line Cat Fish Feed Pellet Machine

One of the largest professional Fish Feed Production Line supplier, our Loya floating fish feed pellet machine design good manufacturing process with great prices and high quality. Low Electricity Fish Meal Fish Feed Production Line Cat Fish Feed Pellet Machine can take rice flour, corn flour, wheat flour, soya flakes meal, rice bran, wheat bran, fish powder, bone powder, fish meal and others as raw materials,to make the Fish Feed Food for sales. The fish feed production line are widely used in various fish, shrimp, crabs, lobsters, etc.

Low Electricity Fish Meal Fish Feed Production Line Cat Fish Feed Pellet Machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Model Number | LY65, LY70, LY 85 |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Automation | Fully Automatic |

| Trial Demonstration | Welcome You To Visit Us At Any Time For Machinery Demonstration |

| Certification | CE BV ISO 9001 |

| Material | Stainless Steel 304 |

| Warranty | 1 YEAR |

| Voltage | 415v/440v/220v/380v/50Hz |

| Main Motor | Sienmens |

| Applicable Industries | Manufacturing Plant, Farms, Food Factory, Other |

Low Electricity Fish Meal Fish Feed Production Line Cat Fish Feed Pellet Machine Detail Introduction :

The Low Electricity Fish Meal Fish Feed Production Line with a Cat Fish Feed Pellet Machine is an innovative setup designed for the production of high-quality fish feed pellets. This line is specially engineered to minimize electricity consumption while maximizing productivity, making it an ideal solution for sustainable and cost-effective feed production.

The fish feed production line adopts twin-screw extruder equipment to meet the needs of floating and sinking fish feed. The advanced aquatic feed pellets produced are widely used in various fish, shrimp, crabs, lobsters, etc. The production process of the food extruder can produce floating and sinking fish feed pellets at the same time. In addition, you can change the degree of extrusion to affect the float time. The machine-made fish balls can float on the water for more than 24 hours.

The automatic stainless steel fish feed production line is composed of feeding system, extrusion system, rotary cutting system, heating system, transmission system and control system. The fish feed machine Adopt advanced twin-screw extrusion technology, use high temperature and high pressure to mature and expand the material, and complete the whole process at one time. The host adopts frequency conversion speed regulation to ensure the stability of the production process. The fish feed have novel shapes, bright colors, various types, natural and lifelike, delicate taste, balanced nutrition, and are widely used in raw materials.

DETAILED DESCRIPTION OF LOW ELECTRICITY FISH MEAL FISH FEED PRODUCTION LINE CAT FISH FEED PELLET MACHINE

The Detail Description Of The Automatic Fish Feed Production Line | |

| Raw materials | Most freshwater fish feed include animal and plant protein. Plant protein adopts corn flour, rice flour, wheat flour, soybean flour, peanut cake powder. Animal protein adopts fish meal, shrimp meal, crab meal, sleeve-fish meal and so on. You can add other ingredient according to the local requirements. |

| Voltage of pet fish food production line | Three phases of food production line: 380V/50Hz, Single phase: 220V/50Hz in china, we can make it according to customers' Local voltage in different countries. |

| Products | Different shapes can be provided according to change the molds. |

| Capacity | 120-150kg/h, 200-250kg/h, 300-500kg/h, 800-1000kg/h,etc. |

| Machine Material | The whole processing line machines are made of stainless steel. |

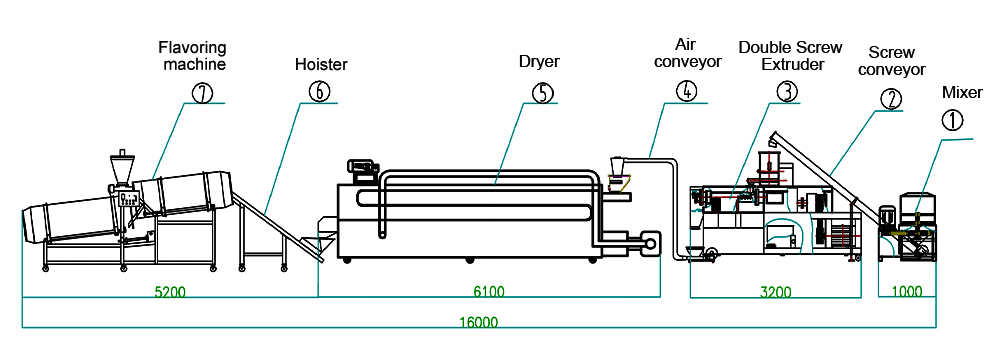

FLOW CHART OF LOW ELECTRICITY FISH MEAL FISH FEED PRODUCTION LINE

Mixer -- Screw Conveyor -- Double Screw Extrude -- Air Conveyor -- Dryer -- Hoister -- Flavoring Machine

TECHNICAL PARAMETERS OF LOW ELECTRICITY FISH MEAL FISH FEED PRODUCTION LINE CAT FISH FEED PELLET MACHINE

DIFFERENT MODEL OF FISH FEED MAKING MACHINE FOR SALE

Technical Parameter Of Full Automatic Fish Feed Production Line | |||

Model | Output | Size (L*W*H) | Price($) |

FFE-65-1 | 120--150kg/h | 22500x1200x2200mm | 16,500-18,900 |

FFE-70-1 | 200-250kg/h | 25000x1500x2200mm | 22,500-26,500 |

FFE-85-1 | 300-600kg/h | 30000x3500x4300mm | 32,500-38,500 |

FFE-90-1 | 1000-1200kg/h | 40000x2400x4000mm | 39,000-42,500 |

FFE-95-2 | 1000-1500kg/h | 40000*3000*4000mm | 44,500-47,000 |

FFE-115-3 | 2T-3Tg/h | 42000x3000x4000mm | 62,000-68,000 |

FFE-130-3 | 4T-5Tkg/h | 46000*3000*4000mm | 75,000-86,000 |

The Fish Feed Making Machine Price Is The Promote Price In 2022. Updated Price PLS Check With Our Pet Food Machine Line Team. | |||

The function of extruder machine is to change the weight of feed, to make floating, slow-sinking and sinking extruded fish feed. The extruder machine manufacturer use fish feed extruder machine produce floating fish feed, sinking fish feed etc. Feed extruder manufacturers to develop technology and recipes for aquaculture. The products can have different shapes, unique flavor, rich Make fish feed for different fish, such as trout, turbot, cod, halibut, yellow tail, sea bass, sea bream, tilapia , aquarium fishes, gold fish, shrimp, prawn etc. fish food extruder machine are designed to produce feed that meets the nutritional requirements of fish and other aquatic animals, with precise size and density control, whilst respecting the highest standards of water quality .

ADVANTAGES OF CAT FISH FEED PELLET MACHINE

The Advantage Of The Industrial Pet Feed Manufacturing Processing Line | |

1 | Improve the palatability of pet food. |

2 | Change or improve the nutritional value of pet food. |

3 | Improve pet food digestion and absorption rate. |

4 | Change the shape and structure of pet food, making it easy for pets to eat. |

5 | Change the content of different nutritional indicators of pet food, then it can reduce moisture of pet food to extend pet food life-time. |

6 | Change the bulk density of food, extrusion granulation, briquette, in order to increase the bulk density of food. |

7 | Kill all kinds of mold, salmonella and other harmful substances, so as to improve the safety of pet food. |

8 | Wide range for cats, dogs, foxes, mink, monkey, pigs, sheep, rabbits, fish, shrimps, poultry, livestock, birds, etc. |

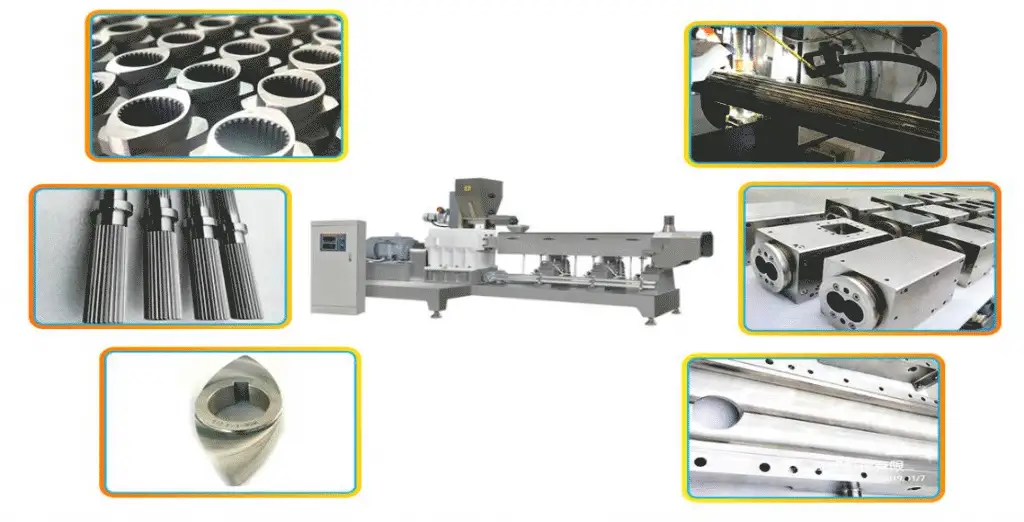

DETAILED MAIN EQUIPMENT PICTURE OF LOW ELECTRICITY FISH MEAL FISH FEED PRODUCTION LINE

This fish feed production line endues pet food with novel shape, unique taste and color. It can meet with other needs of modern market by many superior characteristics, such as scientific nutrition formula and easy assimilation. And this line can also make the pet food cored filling, it will be more popular with modern pets.

APPLICATIONS OF LOW ELECTRICITY FISH MEAL FISH FEED PRODUCTION LINE CAT FISH FEED PELLET MACHINE

The automatic floating fish feed making machine is applied to produce dry and wet type different shapes fish feed (pet fishes, cultured fishes etc.). The puffing degree can be adjusted to produce high quality floating fish feed or sinking feed type. It also can produce dog, cat, bird feed, etc.

According to different output, the fish feed production line also has a variety of configurations. The fish feed machine adjusts the process parameters of temperature, moisture and raw materials to produce food particles with novel shapes, rich taste and balanced nutrition, which are suitable for different pets' tastes. Our fish feed machines are sold to more than 30 countries and regions including South America, Russia, Brazil, Tajikistan, Australia, Ethiopia, Algeria, etc.

What Kind of Of Fish Feed Production Line Has Been Loyal Sold In 2021 ?

Customer Case Of Full Automatic Fish Feed Production Line With The Cheapest Price In 2021 | |

1 | 1T/H Muti-Function Floating Fish Feed Production Line For Sale Senegal Suppliers |

2 | 100kg/h Sinking Fish Food Machine Manufacturing Process Plant For Sale Nigeria |

3 | 100-150Kg/H Pet Dog Fish Food Manufacturing Process Equipment For Sale Burkina Faso Processing |

4 | 250Kg/H Automatic Fish Food Processing Plant Process Machine For Sale Botswana Agent |

5 | 100-150kg/h Floating Fish Food Maker Machine For Sale Philippines Customer Factory Plant |

6 | Ly-75 Industrial Pet Food Machine For Sale Pakistan With Discount Price |

7 | 200kg/h Sinking Fish Food Process Production Line For Sale Mozambique |

High Quality Trader Customer Case Of The Industrial Pet Fish Food Equipment Processing Line Price In 2021 | |

1 | 200kg/h Manufacturing Process Of Fish Dog Food For Sale Bolivia Agent |

2 | 400kg/H Industrial Fish Food Processing Equipment Cost Price For Sale Dominica |

3 | 300kg/h Floating Fish Food Making Manufacturing Processing Line In Senegal Manufacturers |

4 | 100-150Kg/H Pet Fish Extruder Making Machine Process Line Price In Nigeria |

5 | 200-250kg/h Pet Sinking Fish Feed Processing Equipment Factory For Sale Cote d'Ivoire |

6 | Ly-65 Testing Machine For Fish Food Making Machine Cost For Sale Cameroon |

7 | Ly-70 Industrial Pet Food Making Equipment For Sale South Africa Pet Food Suppliers |

Customer Case Of The Commercial Fish Food Manufacturing Equipment With The Farm Setting In 2021 | |

1 | 200-250kg/h Pet Food Manufacturing Equipment For Sale Thailand Agent |

2 | Uzbekistan 100kg/h Fish Food Processing Plant For Sale (Tashkent) |

3 | 500kg/H Extruded Animal Fish Food Processing Machine For Sale Australian Pet Food Machinery Manufacturers |

4 | 100kg/H Pet Fish Feed Making Machine Manufacturing Process For Brazil Suppliers |

Transaction Case Of The Commercial Floating /Sinking Fish Food Making Machine With High Quality Manufacturer In 2021 | |

1 | 200-250kg/h Commercial Fish Feed Manufacturers Food Production Line For Sale Austrian Agent |

2 | Ly65 Capacity Production Lien Process Machine For Sale To Moldova Factory |

3 | 100-150kg/h Fish Feed Processing Equipment For Sale Ukraine |

4 | Ly-65 Small Electric Animal Feed Process Manufacturing Machine For Sale Singapore Factory Plant |

5 | 300kg/h Pet Dog Food Manufacturing Process Extruder For Sale Puerto Rico |

LOYAL’S INTRODUCTION

We are a reliable factory located in the beautiful spring city of Jinan, China.

We have a complete management system ISO9001

We are the largest food processing machinery manufacturer in Jinan, the main products: pet food machinery, snack machinery, fruit and vegetable cleaning and processing machinery, biscuit machinery, instant noodle machinery, pasta machinery, etc. food processing machinery manufacturers!

More than 20 engineers have more than 8 years of work experience and have traveled to more than 50 countries and regions.

Provide 24-hour telephone mail service to provide you with timely and feasible solutions and better after-sales service.

LOYAL’S SERVICE

High-quality after-sales service

1. The distribution map requested by the buyer will be provided.

2. Process operation manual will be provided after delivery.

3. Provide 1 year complete warranty and lifetime maintenance services.

4. Free fragile spare parts will be sent out with the packing box.

5.The first installation can be completed by the equipped engineer.

Engineer services for overseas machinery services

1. Provide free consultation service before, during and after sale.

2. Free project planning and design services.

3. Free debugging of equipment until everything is normal.

4. Free equipment maintenance and personal operation training.

6. Provide free new production process and formula.

Automatic Fish Feed Production Line