Everythingyou Need to Know About Cat Food Machine

Introduction to Cat Food Machine Technology

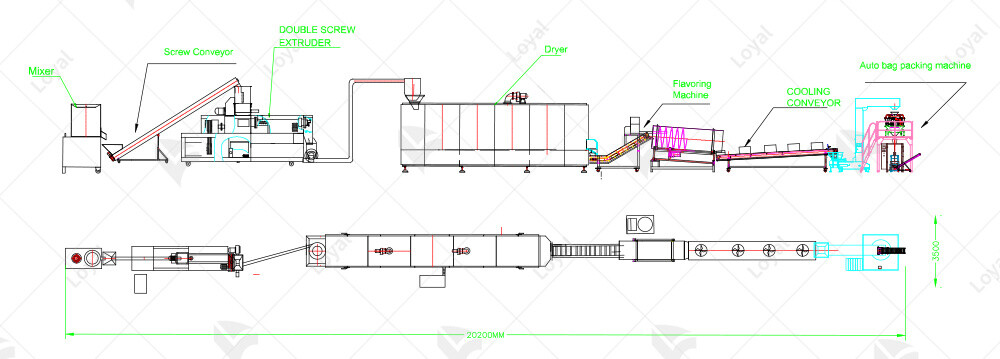

Cat food machine technology encompasses a diverse range of machinery designed specifically for the production of cat food. These machines are integral to the pet food industry, facilitating the efficient processing of ingredients into high-quality cat food products. From mixing and grinding to extrusion and packaging, cat food machines play a crucial role in ensuring the nutritional integrity and palatability of feline diets.

In recent years, advancements in cat food machine technology have led to the development of highly specialized equipment tailored to the unique requirements of cat food production. Manufacturers have invested in research and development to improve the efficiency, reliability, and versatility of these machines, allowing pet food companies to meet the growing demand for premium cat food products.

Types of Cat Food Processing Equipment

1. Mixing and Blending Equipment: Mixing and blending machines are essential for achieving uniform distribution of ingredients in cat food formulations. These machines ensure that all components, including proteins, carbohydrates, vitamins, and minerals, are evenly incorporated to meet feline nutritional requirements.

2. Grinding and Pulverizing Machinery: Grinding and pulverizing equipment is used to process raw ingredients such as meat, grains, and vegetables into fine particles suitable for further processing. This step helps enhance the texture and digestibility of cat food products.

3. Extrusion Systems: Extrusion systems are a key component of cat food production, particularly for manufacturing dry cat food kibble. These machines utilize high temperature and pressure to cook and shape the ingredients into bite-sized pieces with the desired texture and density.

4. Packaging Machinery: Packaging machinery plays a critical role in preserving the freshness and shelf life of cat food products. Automated packaging systems can efficiently fill, seal, and label bags or containers, ensuring product integrity from production to consumption.

5. Quality Control Equipment: Quality control equipment, such as X-ray inspection systems and metal detectors, is essential for ensuring the safety and quality of cat food products. These machines detect foreign objects or contaminants that may compromise product safety.

6. Automation and Robotics: Automation and robotics have revolutionized cat food production by increasing efficiency, reducing labor costs, and improving product consistency. Automated systems can handle tasks such as ingredient weighing, mixing, extrusion, and packaging with precision and speed.

Key Components and Features of Cat Food Machines

Cat food machines are sophisticated pieces of equipment designed specifically for the production of high-quality cat food products. These machines typically consist of several key components and incorporate various features to ensure efficient and precise processing.

One of the primary components of a cat food machine is the mixing chamber, where ingredients such as meat, grains, vitamins, and minerals are combined to form a homogenous mixture. The mixing chamber is equipped with blades or paddles that thoroughly blend the ingredients to achieve uniformity in the final product.

Another essential component is the extruder, which plays a central role in the production process. The extruder uses high pressure and temperature to cook the raw ingredients and shape them into the desired form, such as kibble or pellets. Modern cat food extruders are equipped with advanced controls that allow for precise adjustment of parameters such as temperature, pressure, and screw speed to optimize product quality and consistency.

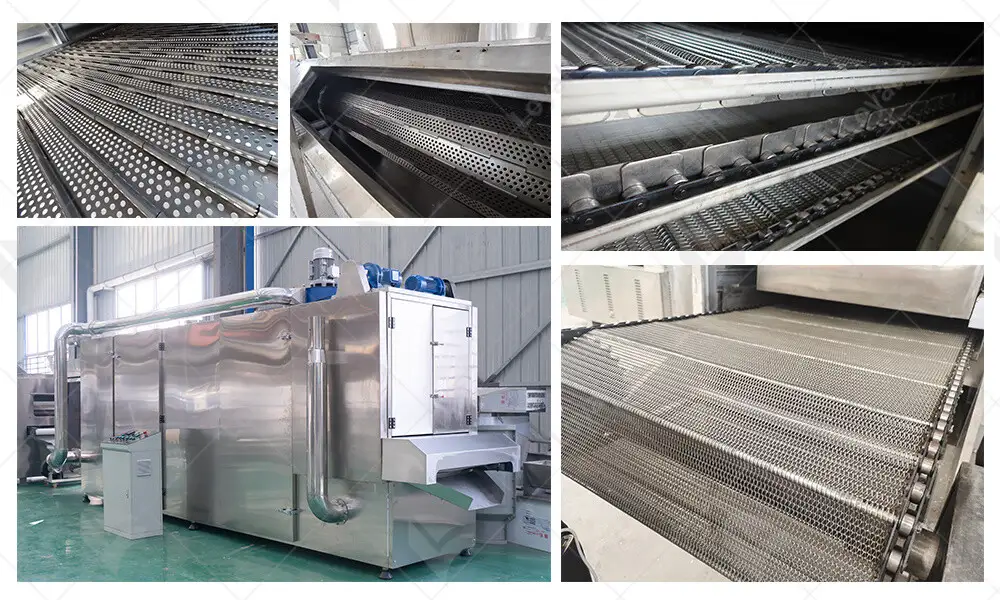

Additionally, cat food machines often feature drying and cooling systems to remove moisture from the extruded product and enhance its shelf stability. These systems may utilize techniques such as hot air drying or vacuum cooling to achieve the desired moisture content and texture.

Cat food machines may include packaging equipment to facilitate the packaging of finished products into bags, cans, or pouches. Packaging features such as gas flushing, vacuum sealing, and portion control ensure product freshness and convenience for consumers.

The Role of Extrusion in Cat Food Production

Extrusion technology plays a pivotal role in the production of cat food, offering numerous advantages in terms of product quality, nutritional value, and production efficiency. Extrusion involves the mechanical processing of ingredients under high temperature and pressure to produce a wide range of cat food products, including dry kibble, semi-moist treats, and dental chews.

One of the primary benefits of extrusion is its ability to achieve precise control over the cooking process, resulting in enhanced digestibility and nutrient retention in the final product. The high temperature and pressure conditions during extrusion effectively cook the ingredients, eliminating harmful bacteria and pathogens while preserving the nutritional integrity of essential nutrients such as proteins, vitamins, and minerals.

Furthermore, extrusion allows for the incorporation of functional additives and supplements, such as probiotics, antioxidants, and omega-3 fatty acids, to enhance the health benefits of cat food. These additives can be easily mixed into the extruded dough, ensuring uniform distribution throughout the final product.

Extrusion enables the production of customized cat food formulations tailored to meet specific dietary requirements and preferences. Manufacturers can vary the ingredients, particle size, shape, and texture of the extruded product to create a diverse range of cat food options that cater to different age groups, breeds, and health conditions.

Factors to Consider When Choosing Cat Food Machinery

When selecting cat food machinery, several factors must be taken into account to ensure optimal performance and product quality. Two prominent manufacturers in the field, LOYAL and Axor, offer different solutions, each with its advantages and considerations.

Aspect | LOYAL Cat Food Machine | Axor Cat Food Machine |

Capacity | Higher capacity models | Lower capacity, but specialized |

Versatility | Offers a range of options for different processing needs | Specializes in specific processes |

Hygienic Design | Designed with hygiene standards in mind, easy to clean | Emphasizes cleanliness and sanitation |

Durability | Known for robust construction, suitable for heavy-duty use | Reliable performance with moderate usage |

Energy Efficiency | Offers energy-efficient models, reducing operational costs | Focuses on energy efficiency to a lesser extent |

Quality Control Measures in Cat Food Machinery

Maintaining quality control in cat food machinery operations is essential to ensure the safety and consistency of the final product. Both LOYAL and Axor implement stringent quality control measures to uphold industry standards.

Regular maintenance schedules are crucial for keeping cat food machinery in optimal condition. This includes routine inspections, cleaning, and lubrication of components to prevent breakdowns and ensure smooth operation.

Both manufacturers conduct rigorous quality assurance checks throughout the production process. This involves testing raw materials, monitoring processing parameters, and inspecting finished products for consistency, texture, and nutritional content.

LOYAL and Axor cat food machinery adhere to strict regulatory standards set by governing bodies to ensure compliance with food safety regulations. This includes meeting requirements for sanitation, hygiene, and traceability throughout the production chain.

Proper training of personnel operating cat food machinery is paramount to maintaining quality control. Both manufacturers invest in comprehensive training programs to ensure operators are knowledgeable about equipment operation, safety protocols, and quality control procedures.

By implementing these quality control measures, cat food manufacturers can uphold the highest standards of product quality, safety, and consistency, ultimately ensuring customer satisfaction and brand reputation.

Safety Standards and Regulations for Cat Food Machines

Cat food machines are subject to stringent safety standards and regulations to ensure the production of safe and high-quality pet food products. These standards encompass various aspects of machine design, operation, and maintenance to mitigate risks and hazards associated with cat food processing equipment.

Manufacturers of cat food machines must adhere to industry-specific regulations set forth by government agencies such as the Food and Drug Administration (FDA) or equivalent regulatory bodies in different countries. These regulations often dictate requirements related to materials used in machine construction, sanitation protocols, and product labeling to guarantee compliance with food safety standards.

In addition to government regulations, cat food machine manufacturers may also adhere to voluntary industry standards established by organizations like the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO). These standards provide guidelines for equipment design, performance, and safety features to uphold the highest standards of quality and reliability in cat food processing machinery.

Furthermore, cat food manufacturers themselves may implement internal safety protocols and quality assurance measures to ensure the safe operation of cat food machines. This may include regular equipment inspections, employee training on proper machine usage and maintenance, and documentation of operational procedures to maintain consistency and compliance with safety standards.

Overall, adherence to safety standards and regulations is paramount in the cat food industry to safeguard both the health of pets and the trust of consumers. By prioritizing safety in the design, operation, and maintenance of cat food machines, manufacturers can uphold the integrity of their products and contribute to the overall well-being of pets worldwide.

Future Trends in Cat Food Processing Technology

The cat food processing industry is witnessing exciting advancements and innovations driven by evolving consumer preferences, technological breakthroughs, and sustainability initiatives. Several key trends are shaping the future of cat food processing technology, revolutionizing the way pet food is manufactured and consumed.

One prominent trend is the growing demand for customized and specialized cat food formulations tailored to meet the unique dietary needs and preferences of individual pets. This trend has led to the development of advanced processing technologies that enable manufacturers to produce personalized cat food products using innovative ingredients and manufacturing techniques.

Another emerging trend is the integration of digitalization and data analytics in cat food processing operations. By harnessing the power of artificial intelligence (AI), machine learning, and Internet of Things (IoT) devices, manufacturers can optimize production processes, enhance product quality, and minimize waste through real-time monitoring and predictive maintenance.

Moreover, sustainability is becoming an increasingly important consideration in cat food processing technology. Manufacturers are exploring eco-friendly packaging solutions, reducing energy consumption through more efficient processing methods, and sourcing sustainable ingredients to minimize the environmental impact of cat food production.

In summary, the future of cat food processing technology is characterized by innovation, customization, and sustainability. By embracing these trends and leveraging cutting-edge technologies, manufacturers can meet the evolving demands of pet owners while ensuring the health and well-being of their feline companions.

Automation and Robotics in Cat Food Manufacturing

Automation and robotics are revolutionizing cat food manufacturing processes, offering numerous benefits in terms of efficiency, precision, and product consistency. These advanced technologies are increasingly being integrated into various stages of cat food production, from ingredient handling and processing to packaging and quality control.

One of the primary advantages of automation and robotics in cat food manufacturing is improved efficiency and productivity. Automated systems can perform repetitive tasks with greater speed and accuracy than manual labor, leading to increased throughput and reduced production costs. This allows manufacturers to meet growing demand for cat food products while maintaining competitive pricing in the market.

Additionally, automation and robotics enhance product consistency and quality by minimizing human error and variability in manufacturing processes. Robotic systems can precisely measure and dispense ingredients, control cooking and extrusion parameters, and ensure uniformity in product size, shape, and texture. This results in more consistent and standardized cat food products that meet stringent quality standards and consumer expectations.

Furthermore, automation and robotics contribute to improved workplace safety by reducing the need for manual labor in potentially hazardous environments. By automating tasks such as heavy lifting, handling of hot or sharp objects, and repetitive motions, manufacturers can mitigate the risk of workplace injuries and create safer working conditions for employees.

Overall, automation and robotics offer significant opportunities for innovation and efficiency gains in cat food manufacturing. As technology continues to advance, we can expect to see further integration of these technologies into the production processes, driving continuous improvement and innovation in the cat food industry.

FAQs: Frequently asked questions about cat food machine

1. What is a cat food machine?

A cat food machine is a specialized piece of equipment used in the manufacturing process of cat food products.

2. How does a cat food machine work?

A cat food machine processes raw ingredients through various stages such as mixing, extrusion, shaping, and drying to produce finished cat food products.

3. What types of cat food machines are available?

Cat food machines include mixers, extruders, dryers, and packaging equipment tailored for the specific needs of the pet food industry.

4. Are cat food machines safe for use?

Yes, cat food machines are designed and manufactured to meet stringent safety standards and regulations to ensure the production of safe and high-quality pet food products.

5. How do I choose the right cat food machine for my production needs?

When selecting a cat food machine, consider factors such as production capacity, processing capabilities, energy efficiency, and compliance with industry regulations.

References

1. Food and Agriculture Organization of the United Nations (FAO): https://www.fao.org/home/en/

2. American Society of Agricultural and Biological Engineers (ASABE): https://www.asabe.org/

3. The Aquaculture Engineering Society (AES): https://www.aesweb.org/

4. European Aquaculture Society (EAS): https://www.aquaeas.eu/

5. International Aquafeed Magazine:https://www.international-aquafeed.com/