Everything you Need to Know About Microwave Sterilizing Machine

Introduction to Microwave Sterilizing Machine

Microwave Sterilizing Machine, a vital component in the food industry, ensures the safety and longevity of perishable goods. Employing advanced technology, it utilizes microwave radiation to eliminate harmful bacteria, fungi, and pathogens from food products.

Microwave Sterilizing Machines are integral to modern food processing, offering rapid and efficient sterilization without compromising nutritional quality. These machines play a crucial role in preserving food while meeting stringent hygiene standards.

How Microwave Sterilizing Machines Work

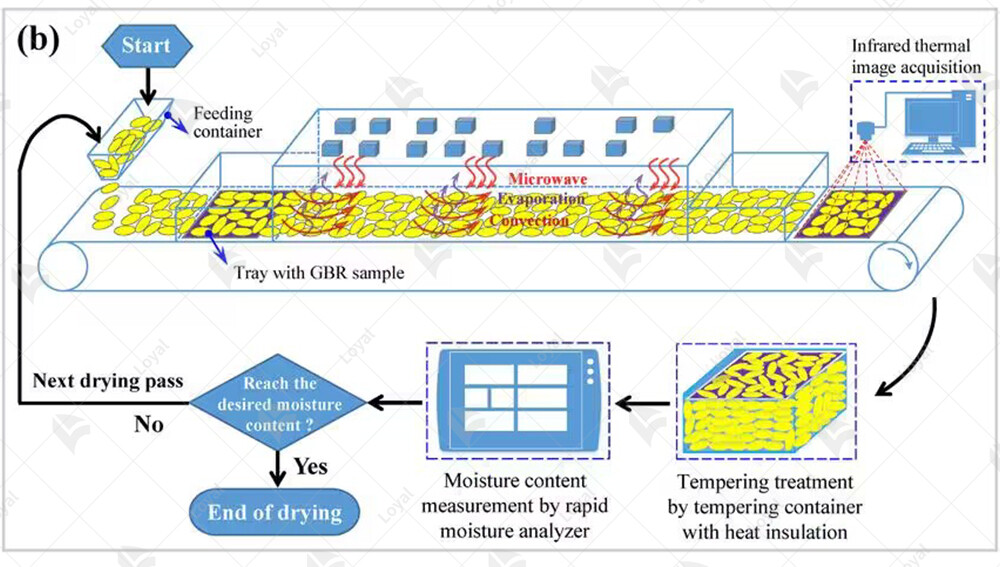

Microwave Sterilizing Machines operate by emitting electromagnetic waves, specifically microwaves, which penetrate food items and disrupt the DNA and cellular structure of microorganisms. This process effectively neutralizes harmful pathogens, ensuring the safety of the food product.

The microwaves generated by the machine cause the water molecules within the food to vibrate rapidly, producing heat. This heat is uniformly distributed throughout the food item, ensuring thorough sterilization without the need for excessive heating or cooking.

Moreover, Microwave Sterilizing Machines offer precise control over sterilization parameters such as temperature and exposure time, allowing for customization according to specific food types and processing requirements.

Overall, Microwave Sterilizing Machines provide a reliable and efficient method for food sterilization, safeguarding consumer health and meeting industry standards for hygiene and safety.

Advantages of Microwave Sterilizing Machines

1. Efficiency: Microwave sterilizing machines offer unparalleled efficiency in the food industry. Their rapid heating capabilities allow for quick sterilization of food products, significantly reducing processing times compared to traditional methods.

2. Uniform Heating: One of the key advantages of microwave sterilizing machines is their ability to ensure uniform heating throughout the food product. Unlike conventional methods that may result in uneven heating, microwaves penetrate the entire product, ensuring thorough sterilization.

3. Preservation of Nutrients: Microwave sterilizing machines preserve the nutritional value of food products. Unlike other sterilization methods that may lead to nutrient loss due to prolonged exposure to heat, microwaves heat food quickly, minimizing nutrient degradation.

4.Energy Efficiency: Microwave sterilizing machines are known for their energy efficiency. They utilize electromagnetic waves to heat the food directly, reducing energy wastage compared to traditional sterilization methods that heat the surrounding environment.

Applications of Microwave Sterilizing Machines

1. Packaged Food: Microwave sterilizing machines are widely used in the sterilization of packaged food products. From canned goods to pre-packaged meals, these machines ensure that the food remains safe for consumption without compromising its quality or taste.

2. Beverages: The beverage industry also benefits from the use of microwave sterilizing machines. These machines can efficiently sterilize liquid products such as juices, dairy products, and beverages in various packaging formats, ensuring a longer shelf life and maintaining product integrity.

3. Pharmaceuticals: In the pharmaceutical industry, microwave sterilizing machines play a crucial role in ensuring the safety and efficacy of medications and medical devices. These machines provide a reliable method for sterilizing pharmaceutical products and packaging materials, meeting stringent regulatory standards.

4.Cosmetics and Personal Care Products: Microwave sterilizing machines are also utilized in the sterilization of cosmetics and personal care products. From creams and lotions to powders and gels, these machines ensure that the products remain free from harmful microorganisms, prolonging their shelf life and ensuring consumer safety.

Factors to Consider When Choosing a Microwave Sterilizing Machine

When selecting a microwave sterilizing machine for your operation, several key factors should be considered to ensure optimal performance and efficiency:

1. Capacity and Throughput Requirements:

Assess the volume of production and the throughput requirements of your operation. Choose a microwave sterilizing machine that can accommodate your production volume while maintaining consistent quality and speed. Consider factors such as batch size, processing time, and production schedule to select the appropriate capacity for your needs.

2. Power and Energy Consumption:

Evaluate the power and energy consumption of the machine to minimize operational costs. Look for models that offer a balance between power efficiency and performance. Opt for energy-saving features such as variable power settings, insulation, and efficient heating mechanisms to reduce energy consumption without compromising sterilization effectiveness.

3. Sterilization Effectiveness and Uniformity:

Ensure that the microwave sterilizing machine provides thorough and consistent sterilization of your products. Look for features such as adjustable power levels, multiple heating zones, and precise temperature control to achieve optimal sterilization effectiveness and uniformity across all batches. Conduct thorough testing and validation to verify the machine's performance before integrating it into your production line.

4. Ease of Operation and Maintenance:

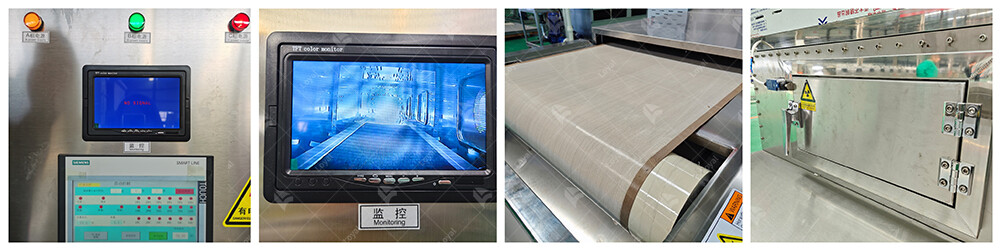

Choose a microwave sterilizing machine with user-friendly controls and intuitive interfaces to simplify operation and reduce the risk of operator errors. Consider features such as automated process controls, programmable settings, and remote monitoring capabilities for enhanced convenience and efficiency. Additionally, prioritize machines with easy access for cleaning and maintenance to minimize downtime and ensure long-term reliability. Regular maintenance and servicing are essential to prolonging the lifespan of the machine and maximizing its performance.

Maintenance and Cleaning Tips for Microwave Sterilizing Machines

Regularly inspecting and cleaning the internal components of the microwave sterilizing machine is essential for maintaining its efficiency and prolonging its lifespan. Follow these additional maintenance and cleaning tips to ensure optimal performance:

1. Cleaning the Interior Cavity: Regularly wipe down the interior surfaces of the sterilization chamber with a mild detergent solution to remove any residue or buildup. Pay special attention to the walls, ceiling, and floor of the cavity, as well as any removable trays or shelves. Rinse thoroughly with clean water and allow the cavity to dry completely before use.

2. Deodorizing the Cavity: To eliminate any lingering odors or bacteria, use a mixture of water and baking soda to wipe down the interior surfaces of the sterilization chamber. Alternatively, you can place a bowl of water with lemon slices or vinegar inside the cavity and run a short sterilization cycle to deodorize and sanitize the interior.

3. Inspecting the Door Seal: Check the integrity of the door seal regularly to ensure a tight and secure fit. A damaged or worn-out door seal can compromise the effectiveness of the sterilization process and lead to leaks or contamination. Replace the seal if any signs of wear or damage are detected.

4. Cleaning the Exterior Surfaces: Wipe down the exterior surfaces of the microwave sterilizing machine with a damp cloth to remove any dust, dirt, or spills. Avoid using abrasive cleaners or harsh chemicals that may damage the finish or control panel. Pay attention to ventilation openings and ensure they are clear of debris to maintain proper airflow.

5. Checking for Leakage: Perform a leakage test periodically to ensure that the microwave sterilizing machine is effectively contained and does not emit harmful radiation. Use a commercial microwave leakage detector or follow manufacturer guidelines to conduct the test accurately. Address any leaks promptly to prevent exposure to radiation hazards.

6. Calibrating Sensors and Controls: Verify the accuracy of temperature and pressure sensors, as well as control settings, by calibrating them regularly according to manufacturer specifications. Calibration ensures consistent and reliable performance during sterilization cycles, minimizing the risk of under or over-processing food products.

7. Scheduled Maintenance Tasks: Create a comprehensive maintenance schedule that includes routine tasks such as lubricating moving parts, checking alignment, and replacing consumable components like filters or bulbs. Adhere to the schedule diligently to prevent unexpected breakdowns and maintain peak operational efficiency.

By incorporating these additional maintenance and cleaning practices into your routine, you can optimize the performance and longevity of your microwave sterilizing machine while ensuring the safety and quality of your sterilized products.

Safety Precautions When Using Microwave Sterilizing Machines

Safety is paramount when operating microwave sterilizing machines in industrial settings. These machines utilize high-powered microwave radiation to effectively sterilize food products. However, improper use can pose serious risks to operators and compromise the quality of the sterilized products.

Operators should undergo comprehensive training on the safe operation of microwave sterilizing machines. Certification programs ensure that operators understand the potential hazards associated with microwave radiation and are equipped with the necessary skills to operate the equipment safely.

Wearing appropriate PPE is essential when working with microwave sterilizing machines. This includes protective clothing, gloves, and safety goggles to minimize exposure to radiation and prevent injuries. Regular inspections of PPE ensure its effectiveness in providing adequate protection.

Regular maintenance and inspection of microwave sterilizing machines are crucial for ensuring their safe operation. This includes checking for any signs of wear or damage, as well as verifying that safety interlocks and shielding mechanisms are functioning properly. Routine inspections help identify potential hazards and prevent accidents before they occur.

Innovations in Microwave Sterilizing Machine Technology

Recent advancements in microwave sterilizing machine technology have led to the development of advanced control systems that optimize sterilization processes. These systems utilize real-time data monitoring and feedback mechanisms to ensure precise control over key parameters such as temperature, pressure, and radiation intensity.

The integration of Internet of Things (IoT) and artificial intelligence (AI) technologies has revolutionized the capabilities of microwave sterilizing machines. IoT-enabled sensors allow for remote monitoring and control of sterilization processes, while AI algorithms analyze data to optimize performance and efficiency.

Newer microwave sterilizing machines are equipped with enhanced safety features to minimize risks to operators and ensure compliance with regulatory standards. These features include improved shielding materials, automated safety interlocks, and emergency shutdown mechanisms to prevent accidents and protect personnel.

Advancements in microwave technology have led to the development of more energy-efficient sterilizing machines. Innovative design features, such as multi-mode heating systems and optimized cavity geometries, minimize energy consumption while maintaining high levels of sterilization efficacy. These energy-efficient solutions help reduce operating costs and environmental impact.

Future Trends in Microwave Sterilizing Machine Development

The future of microwave sterilizing machine development lies in seamless integration with Industry 4.0 principles. This includes interconnected systems that leverage data analytics, machine learning, and automation to optimize sterilization processes, enhance product quality, and streamline operations.

Future microwave sterilizing machines will offer greater customization and flexibility to meet the diverse needs of different industries and applications. Modular designs and adjustable parameters will enable operators to tailor sterilization processes according to specific product requirements, leading to improved efficiency and performance.

There is a growing emphasis on developing sustainable solutions in microwave sterilizing machine technology. This includes reducing energy consumption, minimizing waste generation, and utilizing eco-friendly materials in construction. Innovative approaches such as renewable energy sources and closed-loop systems will drive sustainability in the future of sterilization technology.

Future trends in microwave sterilizing machine development will focus on enhancing food safety and quality through innovative technologies. This includes the integration of sensors for real-time monitoring of product characteristics, as well as advanced algorithms for predictive modeling and quality control. These advancements will ensure that sterilized products meet the highest standards of safety and freshness.

Common Issues and Troubleshooting for Microwave Sterilizing Machines

1. Uneven Heating

Issue: One common issue with microwave sterilizing machines is uneven heating, which can result in inconsistent sterilization of food products.

Troubleshooting: Ensure that the microwave cavity is clean and free of any obstructions that may interfere with the distribution of microwave energy. Check for damaged or faulty heating elements and replace them if necessary. Adjust the positioning of the food products within the cavity to promote more uniform heating.

2. Overheating

Issue: Overheating can occur if the microwave sterilizing machine is operated at excessively high power levels or for extended periods without adequate ventilation.

Troubleshooting: Reduce the power level or shorten the sterilization time to prevent overheating. Ensure that the ventilation system is functioning properly and that air circulation around the machine is not restricted. Monitor the temperature inside the cavity closely and implement temperature control mechanisms if available.

3. Equipment Malfunction

Issue: Equipment malfunction, such as failure of electronic components or mechanical parts, can disrupt the operation of microwave sterilizing machines.

Troubleshooting: Conduct a thorough inspection of the machine to identify any faulty components or worn-out parts. Replace malfunctioning parts promptly to minimize downtime. Regular maintenance and servicing can help prevent equipment malfunction and prolong the lifespan of the machine.

4. Inadequate Sterilization

Issue: Inadequate sterilization may occur if the microwave sterilizing machine is not calibrated correctly or if the sterilization parameters are not optimized for the specific type of food product.

Troubleshooting: Verify that the machine is calibrated according to manufacturer specifications and recalibrate if necessary. Adjust the sterilization parameters, such as temperature, time, and power level, to ensure effective sterilization of the intended food products. Conduct regular microbiological testing to validate the efficacy of the sterilization process.

5. Safety Concerns

Issue: Safety concerns may arise if operators are not properly trained in the safe operation of microwave sterilizing machines or if safety protocols are not followed.

Troubleshooting: Provide comprehensive training to operators on the safe use of microwave sterilizing machines, including proper handling of equipment and adherence to safety protocols. Implement clear safety guidelines and procedures, and enforce compliance through regular inspections and audits. Address any safety issues promptly to mitigate risks to personnel and prevent accidents.

References

1.Tetra Pak : https://www.tetrapak.com

2.Jinan Kelid Machinery Co., Ltd.: http://www.kldfoodmachine.com

3. GEA : https://www.gea.com

4. MAX Industrial Microwave: https://www.maxindustrialmicrowave.com

5. Marel: https://marel.com