Everything you need to know about microwave drying oven In 2024

Introduction

In 2024, the landscape of microwave technology continues to evolve, with microwave drying ovens standing at the forefront of innovation. These specialized ovens utilize microwave energy to efficiently and rapidly dry a variety of materials, ranging from food products to industrial components. As we delve into the realm of microwave drying ovens, it becomes evident that their applications and benefits extend far beyond conventional drying methods. Let's explore everything you need to know about microwave drying ovens in 2024.

Working principle

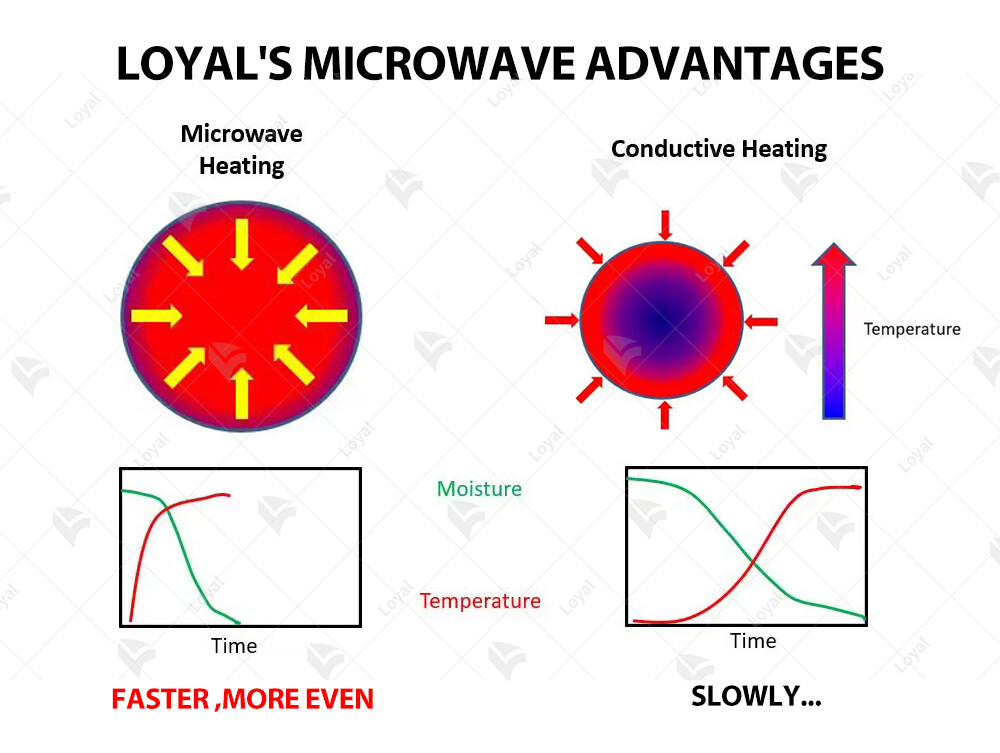

The microwave drying oven, a cornerstone of modern food processing, operates on a simple yet effective principle. It harnesses the power of microwaves, a form of electromagnetic radiation, to generate heat within the food itself. Unlike conventional ovens that rely on external heat sources, such as gas or electric elements, microwave drying ovens penetrate the food with microwaves, causing water molecules within the food to oscillate rapidly. This agitation creates friction, which in turn generates heat, thereby evaporating moisture from the food. As a result, microwave drying not only speeds up the drying process but also preserves the food's flavor, nutrients, and texture more effectively than traditional methods.

Key components of microwave drying oven

Component Name | Description |

Magnetron | The magnetron is the heart of the microwave drying oven, responsible for generating microwaves. It converts electrical energy into electromagnetic radiation at microwave frequencies. |

Waveguide | The waveguide is a hollow metal tube that carries microwaves from the magnetron to the oven cavity. It ensures that the microwaves are directed into the oven in a controlled manner, preventing leakage. |

Turntable | The turntable is a rotating glass plate located at the bottom of the oven cavity. Its purpose is to rotate the food being heated, ensuring even exposure to the microwaves for uniform drying. |

Control Panel | The control panel consists of buttons or a touchscreen interface that allows users to set the desired drying time, temperature, and power level. It also includes indicators for monitoring the oven's status. |

Ventilation System | The ventilation system helps to dissipate heat and steam generated during the drying process. It prevents the buildup of moisture inside the oven cavity, ensuring efficient and safe operation. |

Temperature Sensor | The temperature sensor monitors the temperature inside the oven cavity and regulates the power output of the magnetron accordingly. This ensures precise control over the drying process and prevents overheating. |

Safety Interlock | The safety interlock is a mechanism that prevents the microwave oven from operating when the door is open. It ensures user safety by cutting off power to the magnetron whenever the door is not securely closed. |

Cavity | The cavity is the interior space of the microwave drying oven where the food is placed for drying. It is typically made of metal and designed to reflect and contain the microwaves, maximizing their effect on the food. |

Insulation | Insulation materials are used to minimize heat loss from the oven cavity, improving energy efficiency and reducing the risk of external surfaces becoming too hot to touch. They also help to maintain a consistent drying temperature. |

Stirrer Fan | The stirrer fan is a component that helps to distribute microwaves evenly throughout the oven cavity. It reduces hot spots and ensures uniform drying by circulating air and microwave energy. |

Comparison and advantages of microwave technology and traditional drying methods

Aspect | Microwave Drying Oven | Traditional Drying Methods |

Heating Mechanism | Utilizes electromagnetic waves to directly heat materials | Relies on convection, conduction, or radiation for heating |

Heating Uniformity | Provides more uniform heating throughout the material | Often leads to uneven heating, resulting in quality issues |

Energy Efficiency | Offers higher energy efficiency due to direct heating | Often requires more energy due to indirect heating methods |

Drying Time | Significantly reduces drying time for most materials | Drying time may be prolonged, depending on the method used |

Product Quality | Preserves product quality by minimizing heat exposure | May result in quality degradation due to prolonged heating |

Space and Footprint | Compact designs, suitable for small spaces | May require larger equipment and more space for operation |

Environmental Impact | Reduces carbon footprint with efficient energy usage | May contribute to environmental degradation with higher energy consumption |

Cost-effectiveness | Initial investment might be higher, but long-term savings | Initial costs may be lower, but operational costs may be higher |

Types of microwave drying oven

1. Batch Microwave Drying Oven:

One of the most common types, batch microwave drying ovens are ideal for small to medium-scale operations. They function by exposing materials to microwave radiation within a closed chamber. This controlled environment ensures uniform drying without compromising the integrity of the material.

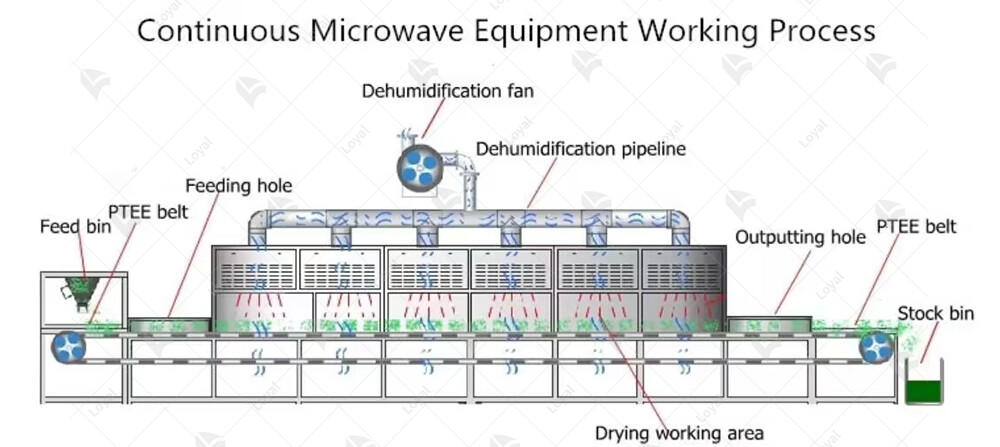

2. Continuous Microwave Drying Oven:

For larger-scale operations requiring uninterrupted drying processes, continuous microwave drying ovens are the go-to choice. These ovens feature a conveyor belt system that allows for a continuous flow of materials through the microwave chamber. This not only enhances productivity but also maintains consistent drying parameters throughout the process.

3. Vacuum Microwave Drying Oven:

Vacuum microwave drying ovens are designed to cater to materials sensitive to oxygen or prone to oxidation. By removing air from the drying chamber, these ovens create a vacuum environment, preventing unwanted reactions while facilitating efficient drying. This type of oven is particularly favored in industries such as pharmaceuticals and electronics, where precise control over drying conditions is paramount.

4. Hybrid Microwave Drying Oven:

Combining the advantages of conventional and microwave drying technologies, hybrid microwave drying ovens offer enhanced flexibility and performance. These ovens utilize both microwave radiation and conventional heating methods, allowing for faster drying rates and improved energy efficiency. They are often utilized in research and development settings where experimentation and optimization are key.

5. Industrial Microwave Drying Oven:

Engineered for heavy-duty applications, industrial microwave drying ovens are rugged, reliable, and capable of handling large volumes of materials. These ovens feature robust construction and advanced control systems to meet the demanding requirements of industrial settings. From food processing to chemical manufacturing, they find widespread use across diverse industries.

Technical parameters

| Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size LWH(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm825mm1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm825mm1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm1160mm1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm1160mm1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm1160mm1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm1450mm1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm1500mm1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm1650mm1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm1650mm1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm1850mm1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm1850mm1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm1850mm1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

| Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

| Microwave Output Frequency | 2450±50Mhz | ||||

| Microwave Input Apparent Power | ≤168Kva | ||||

| Microwave Output Power | ≥120Kw | ||||

| Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

| Ambient Temperature | -5-40°C | ||||

| Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

| Transmission Speed | 0-10m/Min(Adjustable) | ||||

Application of Microwave Drying Oven

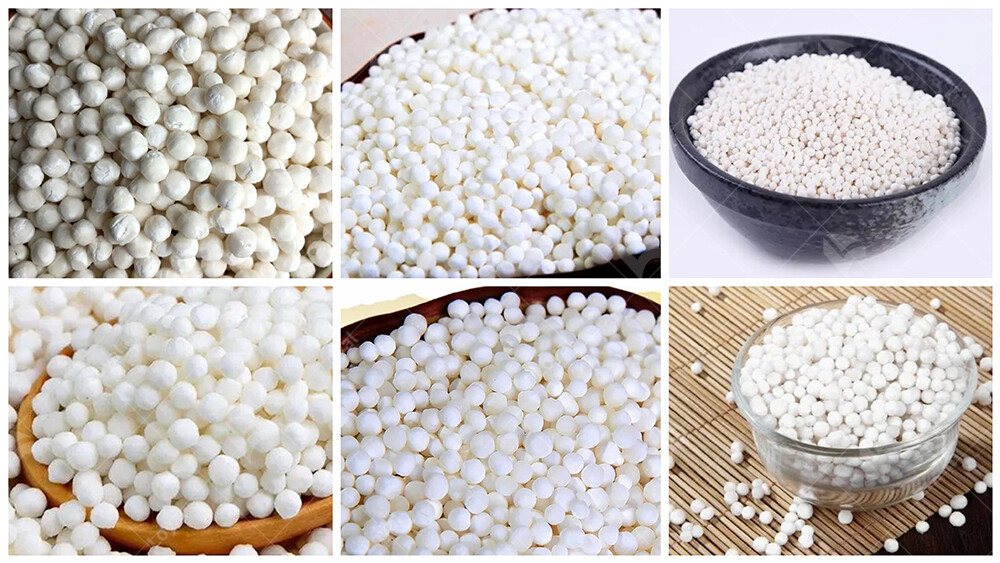

In 2024, the application of microwave drying ovens has reached unprecedented levels of efficiency and versatility. These innovative appliances have revolutionized various industries, offering a rapid and uniform drying process that preserves the quality of materials while enhancing productivity.

Food Industry:

Microwave drying ovens have become indispensable tools in the food industry. From fruits and vegetables to meat products and grains, these ovens efficiently remove moisture while retaining flavor, color, and nutrients. This technology ensures quicker processing times and extends the shelf life of perishable goods, meeting the demands of modern consumers for convenience and quality.

Pharmaceutical Sector:

In pharmaceutical manufacturing, precision and consistency are paramount. Microwave drying ovens provide a sterile and controlled environment for drying medicinal herbs, active ingredients, and pharmaceutical formulations. By eliminating moisture content effectively, these ovens maintain the potency and efficacy of drugs, contributing to the production of high-quality pharmaceuticals.

Chemical Processing:

The chemical industry benefits immensely from the use of microwave drying ovens. These ovens facilitate the drying of various chemical compounds, catalysts, and intermediates without compromising their chemical integrity. The rapid drying process reduces production time and energy consumption, optimizing efficiency and cost-effectiveness in chemical processing operations.

Materials Science:

Microwave drying ovens play a crucial role in materials science research and development. They enable the drying of diverse materials such as ceramics, polymers, and composites with precision and control. This technology accelerates the drying process, allowing researchers to study material properties and characteristics more efficiently, leading to advancements in materials engineering and manufacturing.

Environmental Applications:

In environmental science and engineering, microwave drying ovens offer sustainable solutions for wastewater treatment and sludge management. These ovens efficiently remove moisture from organic waste materials, reducing volume and mitigating environmental pollution. By incorporating microwave technology into waste drying processes, industries can achieve environmental compliance while minimizing operational costs.

Precautions for the selection and implementation of microwave drying oven

1. Understanding the Technology

Microwave drying ovens utilize electromagnetic radiation in the microwave frequency range to heat and dry materials quickly and uniformly. Unlike conventional drying methods, such as hot air convection or infrared heating, microwave drying offers advantages such as faster drying times, reduced energy consumption, and better preservation of product quality.

2. Considerations for Selection

When selecting a microwave drying oven, it is essential to consider factors such as power output, frequency, cavity size, and control features. Higher power output and appropriate frequency are crucial for achieving desired drying rates, while cavity size should accommodate the volume of material to be dried. Advanced control features, such as temperature and moisture sensors, enhance precision and control over the drying process.

3. Safety Precautions

Microwave drying involves exposure to electromagnetic radiation, necessitating precautions to ensure operator safety. Proper shielding and interlocking mechanisms prevent leakage of microwave energy, while clear warning signs and safety protocols minimize the risk of accidental exposure. Additionally, regular maintenance and calibration of equipment are essential to uphold safety standards and prevent malfunction.

4. Implementation Considerations

Successful implementation of a microwave drying oven requires thorough planning and integration into existing processes. Proper installation, calibration, and training of personnel are essential to maximize efficiency and minimize downtime. Moreover, conducting trials and optimization studies can help fine-tune drying parameters and ensure consistent results.

5. Regulatory Compliance

Incorporating a microwave drying oven into industrial processes necessitates compliance with regulatory standards and guidelines. Manufacturers should ensure that their equipment meets relevant safety and performance standards set forth by regulatory authorities. Adherence to these standards not only ensures legal compliance but also reflects a commitment to quality and safety.

6. Future Trends

As technology advances, the landscape of microwave drying ovens continues to evolve. Innovations such as intelligent control systems, real-time monitoring, and automation are poised to revolutionize the drying industry, offering greater efficiency, reliability, and customization options. Keeping abreast of these developments and embracing emerging technologies will be critical for staying competitive in the evolving market landscape.

Challenges and Limitations of Microwave Drying Oven

1. Uneven Heating:

One of the primary challenges faced with microwave drying ovens is the issue of uneven heating. Due to the nature of microwave energy, certain areas within the oven may absorb more energy than others, leading to inconsistent drying results. This can result in product quality variations and may necessitate additional monitoring and adjustment during the drying process.

2. Material Compatibility:

Another limitation of microwave drying ovens lies in their compatibility with certain materials. While microwave drying is highly effective for certain substances such as ceramics, polymers, and some food products, it may not be suitable for materials that are sensitive to electromagnetic radiation or prone to overheating. Manufacturers must carefully evaluate the compatibility of their materials with microwave drying technology to avoid damage or subpar results.

3. Energy Consumption:

Although microwave drying is generally more energy-efficient compared to traditional drying methods, the initial investment in microwave drying equipment can be substantial. Additionally, operating a microwave drying oven at optimal efficiency requires proper calibration and maintenance, which may incur additional costs. Despite the long-term cost savings, some businesses may find the upfront expenses prohibitive.

4. Process Control and Monitoring:

Maintaining precise control over the drying process is essential for achieving consistent results and ensuring product quality. However, monitoring and controlling microwave drying parameters such as temperature, moisture content, and airflow can be challenging. Advanced sensors and automation systems can help address these concerns, but they add complexity and cost to the overall system.

5. Safety Considerations:

Microwave drying involves the use of electromagnetic radiation, which poses potential safety risks if not managed properly. Operators must adhere to strict safety protocols to minimize the risk of exposure to microwave radiation and prevent accidents such as burns or fires. Additionally, proper ventilation and shielding are essential to protect workers and maintain a safe working environment.

Post-maintenance of Microwave Drying Oven

After investing in a microwave drying oven, ensuring its longevity and optimal performance requires diligent post-maintenance. Here, we delve into the essential steps to maintain your microwave drying oven effectively in 2024.

Regular Cleaning and Inspection

Proper maintenance begins with regular cleaning and inspection of the microwave drying oven. Start by unplugging the appliance and allowing it to cool down completely. Remove any food residues or spills from the interior using a mild detergent and water solution. Pay close attention to the door seals and hinges, ensuring they are free from debris or buildup that could affect the oven's sealing ability.

Check for Wear and Tear

Periodically inspect the interior cavity and components of the microwave drying oven for signs of wear and tear. Look out for any cracks, chipped paint, or rust, as these issues can compromise the efficiency and safety of the appliance. Replace any damaged parts promptly to prevent further damage and ensure optimal performance.

Calibration and Adjustment

Calibration plays a crucial role in maintaining the accuracy of temperature and power settings in a microwave drying oven. Verify the oven's performance against a calibrated thermometer and adjust the settings if necessary. This step helps ensure consistent results and prevents overheating or undercooking of food products.

Ventilation System Maintenance

The ventilation system is vital for dissipating heat and preventing the buildup of steam and condensation inside the microwave drying oven. Inspect the vents and filters regularly, removing any obstructions or debris that may impede airflow. Clean or replace the filters as recommended by the manufacturer to maintain optimal ventilation and prevent overheating.

Safety Precautions

Prioritize safety by following all recommended guidelines and precautions outlined in the user manual. Avoid using metal utensils or containers that are not microwave-safe, as they can cause arcing and damage to the oven. Additionally, never operate the microwave drying oven when empty, as this can lead to overheating and damage to the internal components.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]