Everything You Need to Know About Long Needle Japanese Bread Crumbs Extrusion Machinery

Introduction to Long Needle Japanese Bread Crumbs Extrusion Machinery

Long needle Japanese bread crumbs, commonly known as panko, are a staple in the culinary world, offering a distinctive light and crispy texture that enhances a wide variety of dishes. The unique shape and consistency of these breadcrumbs are achieved through specialized Long Needle Japanese Bread Crumbs Extrusion Machinery, which is designed to produce consistently high-quality crumbs.

The production of panko involves a meticulous process that starts with baking loaves of bread to a specific moisture content and texture, followed by a unique extrusion process. Long Needle Japanese Bread Crumbs Extrusion Machinery plays a critical role in this process by ensuring that the bread is extruded into long, needle-like shapes before being dried and processed into the final product. This machinery must be precise and efficient to maintain the integrity and quality of the breadcrumbs.

Modern Long Needle Japanese Bread Crumbs Extrusion Machinery is equipped with advanced technology to ensure consistent product quality, energy efficiency, and ease of operation. These machines are designed to handle high production volumes, making them ideal for both large-scale commercial producers and smaller specialty food manufacturers. With features like automated controls and customizable settings, these machines ensure that every batch of panko meets the rigorous standards expected by chefs and consumers alike.

Key Features of Long Needle Bread Crumbs

The Long Needle Japanese Bread Crumbs Extrusion Machinery is designed with several key features to ensure the production of high-quality bread crumbs. Below is a table that highlights these features and their benefits.

Feature | Benefit |

High Precision Extrusion | Ensures uniform size and shape of long needle bread crumbs. |

Advanced Temperature Control | Maintains consistent quality by regulating the heat throughout the extrusion process. |

Durable Construction | Made with high-quality materials to withstand continuous operation and minimize downtime. |

Energy Efficiency | Designed to reduce energy consumption, making the production process more sustainable. |

Automated Operation | Minimizes manual intervention, reducing labor costs and human error. |

Easy Maintenance | Components are designed for easy access and cleaning, ensuring minimal maintenance time. |

Versatility | Capable of producing various types of bread crumbs with adjustable settings. |

User-Friendly Interface | Simplifies operation with an intuitive control panel and real-time monitoring. |

Safety Features | Equipped with safety mechanisms to protect operators and equipment. |

The combination of these features in the Long Needle Japanese Bread Crumbs Extrusion Machinery ensures a highly efficient and reliable production process, capable of meeting the demands of modern food manufacturing.

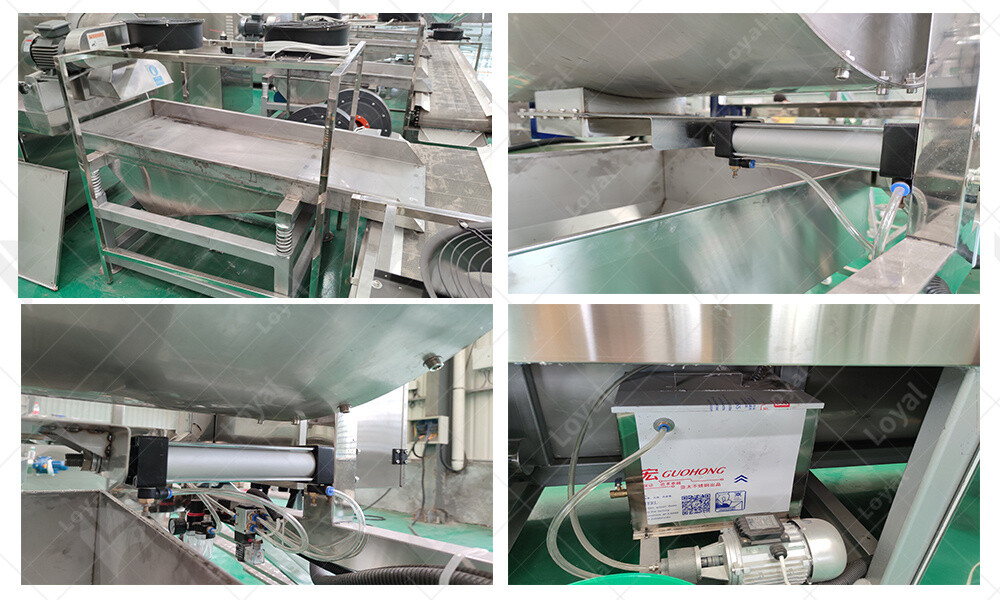

Components of Extrusion Machinery

Extrusion machinery is essential in the production of Long Needle Japanese Bread Crumbs Extrusion Machinery. Below is a detailed table outlining the key components of this sophisticated equipment:

Component | Description |

Hopper | The entry point for raw materials, where ingredients are fed into the extrusion machinery. |

Extruder Barrel | A heated cylindrical chamber where the raw material is processed and pushed through by a screw. |

Screw Conveyor | A rotating screw that moves the raw material through the extruder barrel, ensuring even mixing. |

Die Plate | A metal plate with specific shapes and sizes that the material is forced through, forming the desired product. |

Cutting Mechanism | Located just outside the die, this component cuts the extruded product into uniform pieces. |

Cooling System | A series of cooling fans or a water-cooled jacket to bring the extruded product to the desired temperature. |

Control Panel | An interface for operators to manage and monitor the extrusion process, including temperature and speed adjustments. |

Feeding System | Ensures a consistent and controlled supply of raw material to the hopper. |

Heating Elements | Provides the necessary heat to the extruder barrel for cooking and processing the raw material. |

Output Conveyor | Transports the finished product away from the machine for further processing or packaging. |

How Extrusion Machinery Works

The operation of Long Needle Japanese Bread Crumbs Extrusion Machinery is a sophisticated process that ensures the production of high-quality bread crumbs with specific characteristics.

Raw Material Feeding The process begins with the feeding of raw materials into the hopper. This is where ingredients such as flour, yeast, and other additives are introduced into the system. The feeding system ensures a continuous and consistent flow of materials into the extrusion machinery.

Mixing and Heating Once inside the extruder barrel, the raw materials are subjected to intense mixing and heating. The screw conveyor plays a crucial role here, rotating and pushing the mixture forward. The heating elements surrounding the barrel raise the temperature to the necessary level for cooking the mixture. This step is critical as it transforms the raw materials into a homogeneous and pliable dough.

Shaping and Cutting As the dough reaches the end of the extruder barrel, it is forced through the die plate. The die plate determines the shape and size of the bread crumbs. For Long Needle Japanese Bread Crumbs Extrusion Machinery, the die plate is specifically designed to create long, thin strands. Immediately after extrusion, the cutting mechanism slices these strands into uniform lengths, ensuring consistency in the final product.

Cooling and Packaging The freshly extruded and cut bread crumbs are still hot and pliable. They pass through the cooling system, where they are brought down to the desired temperature. This step is essential to set the texture and firmness of the bread crumbs. Finally, the cooled product is transported via the output conveyor for packaging or further processing. Proper packaging ensures the bread crumbs remain fresh and ready for use.

Maintenance of Extrusion Machinery

Maintaining Long Needle Japanese Bread Crumbs Extrusion Machinery is crucial for ensuring consistent performance and longevity. Regular maintenance involves several key practices:

Routine Cleaning: Ensure the extrusion machinery is cleaned thoroughly after each use. This prevents buildup of residue that can cause blockages and reduce efficiency. Regular cleaning of all parts, especially the extrusion head, is essential.

Lubrication: Regularly lubricate moving parts to reduce friction and wear. Use appropriate food-grade lubricants to avoid contamination. Proper lubrication ensures the machinery runs smoothly and minimizes downtime due to mechanical failures.

Inspection and Replacement: Periodically inspect all components for signs of wear and tear. Pay special attention to the screws, barrels, and dies. Replace any worn-out parts promptly to maintain the integrity of the extrusion process.

Calibration: Regularly calibrate the machinery to ensure it operates within the specified parameters. Accurate calibration ensures the production of consistent, high-quality Long Needle Japanese Bread Crumbs. Calibration should be done by trained personnel using precise instruments.

Benefits of Using Long Needle Bread Crumbs

Using Long Needle Japanese Bread Crumbs Extrusion Machinery offers several benefits, which can be effectively summarized in the table below:

Benefit | Description |

Enhanced Texture | Long needle bread crumbs provide a unique texture that is ideal for various culinary applications, enhancing the final product's mouthfeel. |

Uniformity in Size and Shape | The extrusion process ensures that the bread crumbs are consistently uniform, which is crucial for both aesthetic and functional purposes in food preparation. |

Improved Efficiency | Long Needle Japanese Bread Crumbs Extrusion Machinery is designed for high efficiency, reducing production time and increasing output. |

Cost-Effective Production | By using advanced extrusion technology, manufacturers can produce high-quality bread crumbs at a lower cost, optimizing resources and minimizing waste. |

Versatility | This machinery can be adjusted to produce different sizes and shapes of bread crumbs, catering to various market demands. |

Durability and Reliability | Built with high-quality materials, the machinery ensures long-term durability and consistent performance, reducing the need for frequent repairs. |

These benefits highlight the advantages of investing in Long Needle Japanese Bread Crumbs Extrusion Machinery, making it a valuable asset for food manufacturers aiming to produce superior bread crumb products.

Innovations in Bread Crumbs Extrusion Technology

In recent years, the field of bread crumbs extrusion technology has witnessed significant advancements. The development of Long Needle Japanese Bread Crumbs Extrusion Machinery represents a substantial leap in both efficiency and quality. These innovations include:

Enhanced Precision and Control: Modern Long Needle Japanese Bread Crumbs Extrusion Machinery is equipped with advanced control systems that allow for precise adjustments in temperature, pressure, and screw speed. This results in consistent texture and quality of the bread crumbs.

Energy Efficiency: The latest machinery incorporates energy-saving technologies that reduce power consumption without compromising performance. This not only lowers operational costs but also minimizes environmental impact.

Improved Material Handling: New designs in extrusion machinery have improved the handling of raw materials, ensuring a smoother flow through the extrusion process. This reduces the risk of blockages and ensures a continuous production line.

Versatility in Product Output: The ability to produce various sizes and shapes of bread crumbs with a single machine has become a reality. Long Needle Japanese Bread Crumbs Extrusion Machinery can be easily adjusted to produce fine, coarse, and specialty crumbs to meet diverse market demands.

Troubleshooting Common Extrusion Issues

Effective troubleshooting is essential to maintaining the efficiency and longevity of Long Needle Japanese Bread Crumbs Extrusion Machinery. Below is a detailed table addressing common issues and their solutions:

Issue | Possible Cause | Solution |

Inconsistent crumb size | Incorrect screw speed or pressure settings | Adjust screw speed and pressure to optimal levels |

Excessive wear on extrusion components | Poor quality raw materials or improper usage | Use high-quality raw materials and follow manufacturer guidelines |

Overheating of machinery | Insufficient cooling or ventilation | Check and improve cooling systems and ensure proper ventilation |

Blockages in the extruder | Improper feeding rate or material properties | Adjust feeding rate and ensure materials are within specifications |

Uneven texture of bread crumbs | Variations in temperature or pressure | Calibrate temperature and pressure settings accurately |

Machine vibration | Imbalanced components or loose fittings | Inspect and balance components, tighten any loose fittings |

High energy consumption | Outdated technology or inefficient processes | Upgrade to the latest energy-efficient models and optimize processes |

Frequent breakdowns | Lack of regular maintenance | Implement a rigorous maintenance schedule and use recommended parts |

Cost Considerations for Extrusion Machinery

When evaluating the investment in Long Needle Japanese Bread Crumbs Extrusion Machinery, cost is a critical factor. The initial capital expenditure can be significant, encompassing the purchase of the machinery itself, which ranges from mid to high five-figure sums depending on the model and capacity. This upfront cost must be weighed against the long-term benefits, including increased efficiency and product quality.

Operating costs are another vital consideration. These include energy consumption, maintenance, and labor. Long Needle Japanese Bread Crumbs Extrusion Machinery is designed for energy efficiency, which can lead to substantial savings over time. Maintenance costs, while generally low due to the robust construction of these machines, should not be overlooked. Regular maintenance ensures longevity and optimal performance.

Depreciation and financing are financial aspects that must be accounted for. Understanding the depreciation rate of the machinery can help in planning for future upgrades and replacements. Financing options, whether through loans or leasing, can also impact the overall cost structure, making it essential to explore all available options.

Finally, the potential for increased revenue should be considered. High-quality Long Needle Japanese Bread Crumbs Extrusion Machinery can produce superior products that may command higher prices in the market. This increased revenue potential can offset the initial and ongoing costs, making the investment more attractive.

Case Studies: Successful Implementations

Several companies have successfully integrated Long Needle Japanese Bread Crumbs Extrusion Machinery into their production lines, leading to impressive outcomes. One notable example is a mid-sized bakery that experienced a 30% increase in production capacity after upgrading to this advanced machinery. The consistency and quality of the bread crumbs improved, resulting in better customer satisfaction and repeat business.

Another case involves a large-scale food manufacturer that incorporated Long Needle Japanese Bread Crumbs Extrusion Machinery to streamline its operations. The machinery’s efficiency reduced production time by 25%, allowing the company to meet increasing demand without compromising on quality. This operational efficiency also translated into significant cost savings on labor and energy.

A small artisanal bakery also benefited from this machinery by expanding its product line. With the precise control offered by the extrusion machinery, they were able to produce specialized bread crumbs for gourmet recipes, tapping into a niche market. This diversification helped the bakery increase its market share and profitability.

Lastly, an international food processing company utilized Long Needle Japanese Bread Crumbs Extrusion Machinery to standardize its product quality across multiple locations. The uniformity in production ensured that customers received the same high-quality product regardless of the manufacturing site, enhancing brand reputation and customer loyalty.

Environmental Impact of Bread Crumbs Production

The environmental impact of bread crumbs production is an important consideration, particularly in today’s climate-conscious market. Long Needle Japanese Bread Crumbs Extrusion Machinery has been engineered to minimize environmental footprints. These machines typically use less energy compared to traditional methods, which can significantly reduce carbon emissions.

Moreover, the efficiency of Long Needle Japanese Bread Crumbs Extrusion Machinery results in less waste. By optimizing the production process, these machines ensure that raw materials are used more effectively, reducing the amount of waste generated. This not only benefits the environment but also improves cost efficiency for manufacturers.

Water usage is another critical environmental factor. Many traditional bread crumb production methods require substantial water use, but advanced extrusion machinery can significantly cut down on this necessity. By integrating modern cooling and drying systems, these machines minimize water consumption and mitigate wastewater production.

Finally, the use of recyclable and sustainable materials in the construction of Long Needle Japanese Bread Crumbs Extrusion Machinery further enhances their environmental credentials. Manufacturers are increasingly adopting eco-friendly practices, ensuring that their equipment supports sustainable production processes. This approach not only aids in environmental conservation but also aligns with the growing consumer demand for green products.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com