Everything you need to know about industrial biscuit making machine in 2024

Introduction

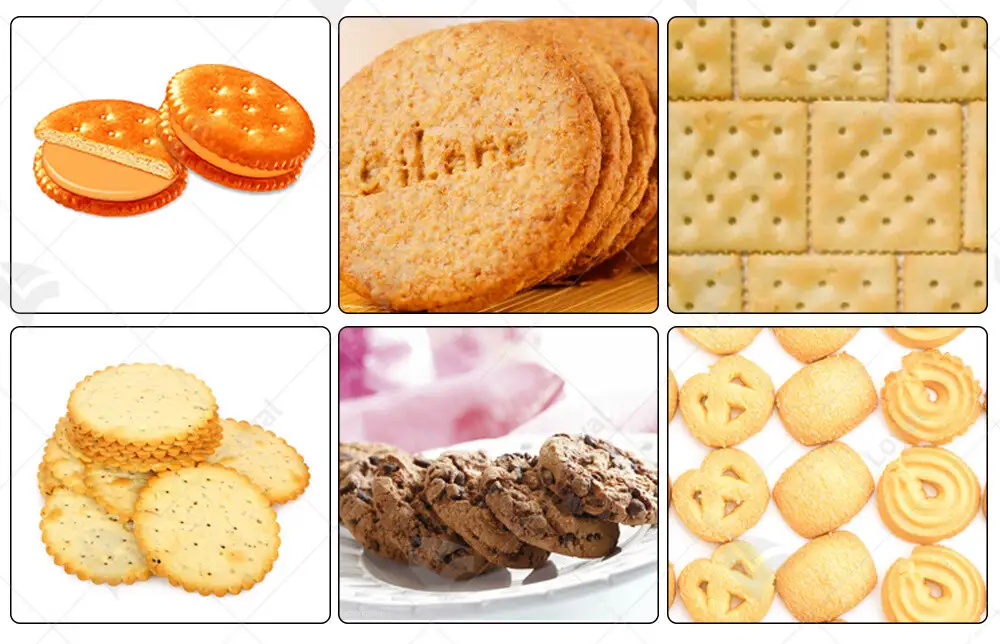

Welcome to the comprehensive guide on industrial biscuit making machines in 2024. In this article, we will delve into the intricate world of industrial biscuit production and the pivotal role played by advanced machinery in this process. Industrial biscuit making machines are the backbone of large-scale biscuit manufacturing, enabling efficient and consistent production of a wide variety of biscuit types. Let's explore the key components, functionalities, and advancements in industrial biscuit making machines that make them indispensable in the modern food industry landscape. Whether you're a seasoned professional or a newcomer to the field, this guide aims to provide valuable insights into the world of industrial biscuit making machines. Let's embark on this enlightening journey together.

Types and Features of Industrial Biscuit Making Machines

| Type of Biscuit Machine | Features |

| Rotary Moulder | - Ideal for producing molded biscuits with intricate designs. |

| - Consists of rotating molds to shape the dough into desired forms. | |

| Wire-Cut Cookie Depositor | - Suitable for producing uniform-sized drop cookies. |

| - Utilizes a wire-cut mechanism to portion and deposit dough onto baking trays. | |

| Dough Sheeter | - Used for rolling and flattening dough to a consistent thickness. |

| - Ensures uniformity in dough thickness for even baking. | |

| Biscuit Oven | - Essential for baking biscuits to perfection. |

| - Available in various configurations, including tunnel ovens for high-volume production. | |

| Cooling Conveyor | - Facilitates the cooling of freshly baked biscuits. |

| - Helps prevent breakage and ensures product quality. | |

| Packaging Machine | - Automates the packaging process for efficient handling. |

| - Offers options for wrapping, sealing, and labeling biscuit products. |

These industrial biscuit making machines are designed to streamline the production process, enhance efficiency, and maintain product consistency. Depending on the specific requirements of a biscuit manufacturing facility, businesses can choose the most suitable type of machine to meet their production goals and quality standards.

Advancements in Technology and Automation

In 2024, the landscape of industrial biscuit making machines is witnessing remarkable advancements in technology and automation. Let's explore the innovations shaping the industry:

1. Automated Ingredient Handling

Modern industrial biscuit making machines are equipped with advanced systems for automated ingredient handling. From flour and sugar to flavorings and additives, these machines precisely measure and dispense ingredients, minimizing human intervention and ensuring consistency in product quality. Automated ingredient handling not only enhances efficiency but also reduces the risk of contamination and human errors.

2. Integrated Control Systems

Integration of sophisticated control systems is a hallmark of technological advancements in industrial biscuit making machines. These systems utilize state-of-the-art sensors, actuators, and programmable logic controllers (PLCs) to monitor and regulate various aspects of the production process. From temperature and humidity control to speed and pressure adjustments, integrated control systems optimize performance and facilitate real-time adjustments for optimal biscuit production.

3. Precision Dough Mixing

Dough mixing is a critical step in biscuit production, and advancements in technology have revolutionized this process. Industrial biscuit making machines now feature precision dough mixing systems that ensure thorough blending of ingredients while minimizing overmixing, which can affect the texture and quality of the final product. High-speed mixing capabilities, coupled with precise ingredient distribution, result in consistent dough quality and improved overall efficiency.

4. Enhanced Product Customization

The demand for customized biscuit products continues to grow, driving manufacturers to innovate in product customization capabilities. Industrial biscuit making machines now offer enhanced flexibility and versatility to accommodate a wide range of biscuit types, shapes, sizes, and textures. Modular designs and adjustable settings allow producers to quickly switch between product configurations, catering to evolving consumer preferences and market trends.

5. Remote Monitoring and Maintenance

Remote monitoring and maintenance capabilities have become integral features of modern industrial biscuit making machines. Cloud-based systems enable manufacturers to remotely monitor machine performance, troubleshoot issues, and implement software updates in real-time. Predictive maintenance algorithms analyze machine data to detect potential issues before they escalate, minimizing downtime and optimizing production efficiency.

Customization and Flexibility Options

When it comes to industrial biscuit making machines in 2024, customization and flexibility options play a crucial role in meeting the diverse needs of manufacturers. Let's explore the various aspects of customization and flexibility available in these machines:

1. Dough Consistency and Texture

Industrial biscuit making machines offer customization options for adjusting dough consistency and texture. This feature allows manufacturers to produce biscuits with varying textures, from crispy to soft, to cater to different consumer preferences. Advanced control systems enable precise adjustments, ensuring consistent quality across batches.

2. Cookie Shapes and Sizes

One of the key advantages of industrial biscuit making machines is their ability to produce biscuits in a wide range of shapes and sizes. Manufacturers can choose from a variety of molds and dies to create biscuits with intricate designs and precise dimensions. Whether it's traditional round biscuits or novelty shapes, these machines offer unparalleled flexibility in cookie production.

3. Production Speed and Capacity

Flexibility in production speed and capacity is essential for meeting fluctuating demand and optimizing production efficiency. Industrial biscuit making machines are equipped with adjustable settings for speed and output, allowing manufacturers to ramp up or slow down production as needed. This flexibility ensures that production remains efficient and responsive to market demands.

4. Ingredient Variation and Recipe Adaptation

Manufacturers often require the flexibility to use different ingredients and adapt recipes to meet consumer preferences or regulatory requirements. Industrial biscuit making machines are designed to accommodate a wide range of ingredients, from various types of flour to flavorings and additives. Additionally, these machines offer programmable settings for recipe adaptation, allowing manufacturers to experiment with new formulations while maintaining consistent quality.

5. Modular Design and Add-On Features

Modular design and add-on features enhance the customization options available in industrial biscuit making machines. Manufacturers can customize their machines with additional modules and accessories to expand functionality or adapt to specific production requirements. Whether it's adding a chocolate coating unit or incorporating a sandwiching mechanism, modular design enables endless possibilities for customization.

In conclusion, customization and flexibility options in industrial biscuit making machines empower manufacturers to innovate, adapt, and meet the evolving demands of the market in 2024. By leveraging these features, manufacturers can achieve greater efficiency, consistency, and versatility in biscuit production, ultimately driving success in the competitive food industry landscape.

Maintenance and Servicing Considerations

Maintaining an industrial biscuit making machine is paramount to ensure optimal performance and longevity. Here are the key considerations for maintenance and servicing:

1. Regular Cleaning

Proper cleaning is essential to prevent contamination and maintain hygiene standards. Components such as hoppers, conveyors, and nozzles should be cleaned thoroughly after each production run. Use food-grade cleaning agents and follow manufacturer guidelines for effective sanitation.

2. Lubrication

Regular lubrication of moving parts is crucial to reduce friction and prevent premature wear and tear. Follow the manufacturer's recommendations for the type and frequency of lubrication. Over-lubrication can attract dust and debris, leading to equipment malfunctions, so ensure proper application.

3. Inspection of Wear Parts

Periodically inspect wear parts such as belts, gears, and seals for signs of damage or deterioration. Replace worn or damaged parts promptly to prevent unexpected breakdowns during production. Keep spare parts on hand to minimize downtime.

4. Calibration and Adjustment

Calibrate and adjust the machine settings regularly to maintain accuracy and consistency in production. This includes checking dough consistency, cookie thickness, and baking temperature. Calibration ensures uniform product quality and minimizes wastage.

5. Preventive Maintenance Schedule

Implement a preventive maintenance schedule to address potential issues before they escalate. This may include routine inspections, component replacements, and performance testing. A proactive approach to maintenance helps identify and rectify problems early, reducing the risk of costly repairs and downtime.

6. Training for Operators

Provide comprehensive training for machine operators on proper operation and maintenance procedures. Ensure operators understand the importance of regular maintenance tasks and encourage them to report any abnormalities or malfunctions promptly. Well-trained staff contribute to smoother operations and extended equipment lifespan.

7. Manufacturer Support and Service Contracts

Consider investing in manufacturer service contracts or support packages for additional peace of mind. These contracts often include scheduled maintenance visits, priority support, and discounted spare parts. Manufacturer technicians are familiar with the equipment and can provide expert troubleshooting and repair services.

8. Documentation and Record-Keeping

Maintain detailed records of maintenance activities, including cleaning schedules, lubrication logs, and equipment inspections. Documentation helps track maintenance history, identify recurring issues, and comply with regulatory requirements. It also facilitates equipment audits and warranty claims.

9. Continuous Improvement

Regularly review and assess the effectiveness of maintenance procedures to identify areas for improvement. Solicit feedback from operators and maintenance personnel to identify pain points and implement corrective actions. Continuous improvement ensures that maintenance practices evolve with changing production requirements and technology advancements.

Cost Analysis and Return on Investment (ROI)

Investing in an industrial biscuit making machine entails careful consideration of costs and the expected return on investment (ROI). Let's delve into the key factors to analyze when assessing the cost-effectiveness of industrial biscuit making machines in 2024.

1. Initial Investment Cost

The initial purchase price of an industrial biscuit making machine is a significant component of the overall investment. Prices can vary widely depending on factors such as brand, capacity, features, and technological advancements. It's essential to compare prices from different manufacturers and assess the value proposition offered by each machine.

2. Operational Costs

Operational costs associated with running an industrial biscuit making machine include expenses such as raw materials, energy consumption, labor, maintenance, and overheads. Analyzing these ongoing costs is crucial for estimating the total cost of ownership over the machine's lifespan. Energy-efficient machines may have higher upfront costs but lower operational expenses, resulting in long-term savings.

3. Production Efficiency and Output

The production efficiency and output capacity of an industrial biscuit making machine directly impact its cost-effectiveness. Machines that can produce a higher volume of biscuits in a shorter time frame may command a higher price but offer greater productivity and revenue generation potential. Evaluating the machine's throughput and efficiency is essential for assessing its ROI.

4. Maintenance and Servicing

Regular maintenance and servicing are essential for ensuring the smooth operation and longevity of an industrial biscuit making machine. Budgeting for maintenance costs, including spare parts and technician fees, is necessary to prevent unexpected downtime and costly repairs. Machines with robust design and reliable performance may incur lower maintenance expenses over time.

5. Return on Investment (ROI)

Calculating the ROI of an industrial biscuit making machine involves estimating the financial benefits derived from its use compared to the initial investment and ongoing costs. Factors to consider include increased production capacity, labor savings, improved product quality, market expansion opportunities, and potential revenue growth. A positive ROI indicates that the investment in the machine is financially viable and yields satisfactory returns over time.

Market Trends and Future Outlook

In the ever-evolving landscape of industrial biscuit making machines, staying abreast of market trends and anticipating future developments is essential for businesses to maintain competitiveness and meet consumer demands. Let's explore the current market trends and future outlook for industrial biscuit making machines in 2024.

1. Technological Advancements

As technology continues to progress, industrial biscuit making machines are expected to undergo significant advancements in 2024. Manufacturers are increasingly integrating cutting-edge technologies such as artificial intelligence (AI), machine learning, and Internet of Things (IoT) into their machines. These technological innovations enhance automation, improve efficiency, and enable real-time monitoring and control of production processes.

2. Customization and Flexibility

Consumer preferences are becoming more diverse and dynamic, driving the demand for customized biscuit products. In response, industrial biscuit making machines are being designed with greater flexibility and customization capabilities. Manufacturers are offering machines that can produce a wide variety of biscuit shapes, sizes, and flavors, allowing producers to cater to niche markets and consumer preferences effectively.

3. Sustainability Initiatives

Sustainability has become a pressing concern across industries, including food production. In 2024, there is a growing emphasis on sustainability initiatives within the biscuit manufacturing sector. Industrial biscuit making machines are being developed with eco-friendly features and materials to minimize environmental impact. Additionally, manufacturers are implementing energy-efficient technologies and waste reduction measures to promote sustainable production practices.

4. Market Expansion and Globalization

The global market for biscuits and baked goods continues to expand, driven by factors such as population growth, urbanization, and changing dietary habits. As a result, industrial biscuit making machine manufacturers are increasingly focusing on global market penetration and expansion. This includes establishing strategic partnerships, expanding distribution networks, and adapting machines to meet the specific needs and preferences of diverse international markets.

5. Demand for Healthier Options

With growing awareness of health and wellness, consumers are seeking healthier biscuit options made with natural ingredients and fewer additives. In response to this trend, industrial biscuit making machine manufacturers are developing machines capable of producing healthier biscuit variants, such as whole grain, gluten-free, and low-sugar options. These machines are equipped with features to ensure precise ingredient measurement and consistent product quality, meeting the demand for healthier biscuits without compromising taste or texture.

6. Integration of Digitalization

Digitalization is revolutionizing the manufacturing industry, and the biscuit making sector is no exception. In 2024, industrial biscuit making machines are increasingly integrated with digital technologies to streamline production processes, enhance operational efficiency, and enable data-driven decision-making. Machine connectivity, data analytics, and predictive maintenance are becoming standard features, allowing manufacturers to optimize production performance and minimize downtime.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/