Everything you Need to Know About High Production Crispy Panko Breadcrumb Production

Overview of Panko Breadcrumb Production

Panko breadcrumbs, known for their light, airy texture and crispy bite, are a staple in various culinary applications. High production crispy panko breadcrumb production involves several critical stages, starting from dough preparation to baking and grinding. This meticulous process ensures that the final product meets the desired standards of crispiness and texture.

The production begins with the preparation of a specialized dough. Unlike traditional breadcrumbs, panko dough is yeast-leavened, which contributes to its unique texture. The dough is carefully mixed to achieve the perfect consistency before it is spread thinly and baked. This baking step is crucial in high production crispy panko breadcrumb production, as it sets the structure of the crumbs.

After baking, the product is allowed to cool before it is ground into the characteristic large flakes. The grinding process in high production crispy panko breadcrumb production must be controlled precisely to ensure uniformity in size and shape. This uniformity is vital for achieving consistent results in culinary applications, making panko breadcrumbs a preferred choice among chefs and food manufacturers.

Key Equipment for Panko Breadcrumb Manufacturing

The backbone of high production crispy panko breadcrumb production lies in the specialized equipment used throughout the process. Each piece of machinery plays a crucial role in maintaining the quality and efficiency of production.

Firstly, the dough mixer is a pivotal component. It ensures that the yeast-leavened dough is mixed to perfection, with the right balance of ingredients. In high production crispy panko breadcrumb production, the mixer must be capable of handling large volumes while maintaining consistency, which is essential for the quality of the final product.

The baking oven is another critical piece of equipment. This oven must provide even heat distribution to ensure that the dough bakes uniformly. The temperature and baking time are meticulously controlled to develop the light, airy texture that panko breadcrumbs are known for. High-quality ovens designed for high production crispy panko breadcrumb production can handle continuous operation, a necessity for large-scale manufacturing.

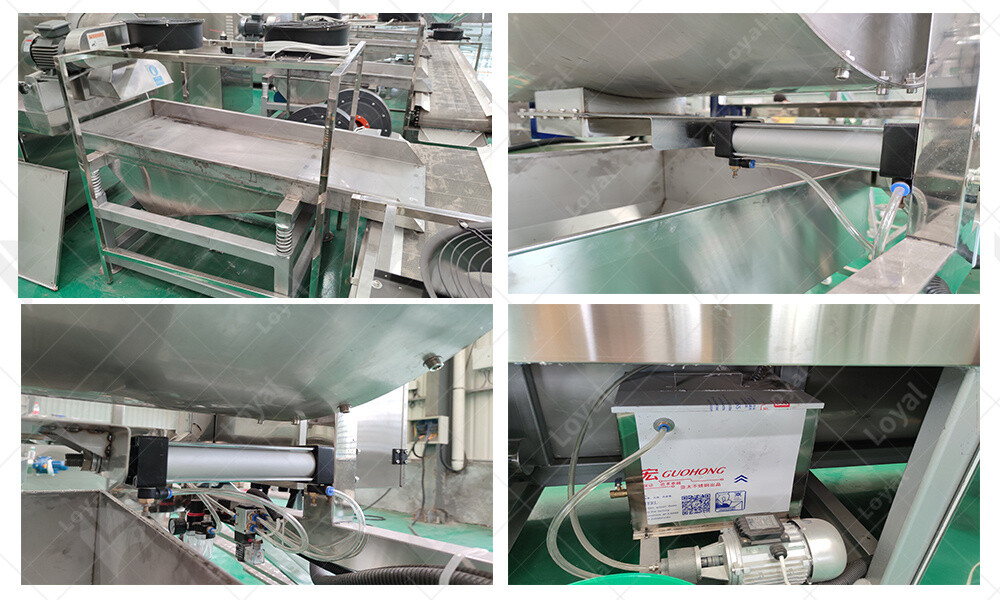

After baking, the cooling conveyors play a vital role. These conveyors ensure that the baked sheets cool down uniformly, preventing any moisture retention that could affect the crispiness. In high production crispy panko breadcrumb production, efficient cooling is paramount to maintaining the product's texture and extending its shelf life.

Finally, the grinding machine is essential for producing the distinctive flaky texture of panko breadcrumbs. This machine must be able to produce uniform flakes without generating excessive heat, which could compromise the product's quality. High-performance grinders designed for high production crispy panko breadcrumb production are equipped with advanced features to ensure consistency and efficiency in the grinding process.

High Production Techniques for Panko Breadcrumbs

Producing High Production Crispy Panko Breadcrumbs efficiently requires advanced machinery and streamlined processes. The first technique involves using an automated dough mixer, which ensures the dough consistency is optimal for creating light and airy breadcrumbs. This consistency is crucial for achieving the desired texture in High Production Crispy Panko Breadcrumb Production.

Another vital technique is the use of specialized baking ovens. These ovens are designed to bake the dough evenly and maintain the right moisture level, essential for crispy panko breadcrumbs. Ensuring uniform heat distribution is key to the High Production Crispy Panko Breadcrumb Production process.

A third technique is the implementation of automated cutting and drying machines. These machines cut the baked dough into uniform pieces and then dry them to achieve the crispy texture that is characteristic of panko breadcrumbs. This step is critical in maintaining high production rates while ensuring product quality.

Lastly, packaging in high production settings involves automated systems that handle the breadcrumbs with care to avoid breakage. The packaging machines must be able to operate at high speeds while maintaining the integrity of the High Production Crispy Panko Breadcrumbs.

Benefits of High Production Panko Breadcrumbs

The primary benefit of High Production Crispy Panko Breadcrumb Production is the ability to meet large-scale demand efficiently. Industrial food manufacturers can produce large quantities of high-quality panko breadcrumbs, ensuring a steady supply for various culinary applications.

Another benefit is consistency in product quality. High production techniques allow for uniformity in texture and flavor, which is crucial for maintaining consumer satisfaction. Consistent High Production Crispy Panko Breadcrumbs enhance the reputation of manufacturers in the competitive food industry.

Cost efficiency is also a significant benefit. By optimizing production processes and utilizing automated machinery, manufacturers can reduce labor costs and minimize waste. This efficiency in High Production Crispy Panko Breadcrumb Production translates to cost savings and competitive pricing for consumers.

Finally, high production capabilities enable manufacturers to innovate and diversify their product offerings. With a reliable and efficient production process, companies can experiment with different flavors and textures of panko breadcrumbs, expanding their market reach and catering to diverse consumer preferences. This adaptability is a key advantage in the dynamic food industry.

Industrial Ovens for Crispy Panko Production

Industrial ovens play a pivotal role in achieving high production rates and consistent quality in crispy panko breadcrumb production. These specialized ovens are designed with precision engineering to meet the demanding needs of modern food processing facilities.

High Production Capability

Industrial ovens used in crispy panko breadcrumb production are distinguished by their high production capabilities. They are equipped with advanced conveyor systems that ensure a continuous flow of breaded products through the baking process. This continuous operation not only enhances efficiency but also maintains uniformity in the texture and crispiness of the breadcrumbs.

Precision Baking Technology

The key to achieving the perfect crispy texture lies in the precision baking technology integrated into these industrial ovens. They are equipped with temperature and humidity control systems that are meticulously calibrated to achieve optimal baking conditions for panko breadcrumbs. This precise control ensures that each batch of breadcrumbs meets the exact specifications required by food manufacturers.

Energy Efficiency and Sustainability

In addition to their high production capacity and precise baking capabilities, industrial ovens for panko breadcrumb production are designed with energy efficiency in mind. They utilize advanced insulation materials and heat recovery systems to minimize energy consumption without compromising on baking performance. This not only reduces operational costs but also aligns with sustainability goals, making them an environmentally responsible choice for food processing facilities.

Quality Assurance and Compliance

Industrial ovens used in the production of crispy panko breadcrumbs adhere to stringent quality assurance standards and regulatory compliance. They are constructed from food-grade materials and undergo rigorous testing to ensure they meet industry-specific hygiene and safety requirements. This commitment to quality and compliance underscores their reliability in maintaining food safety and product integrity throughout the baking process.

Mixing and Blending Equipment for Panko

In the realm of industrial food machinery, achieving high production levels of High Production Crispy Panko Breadcrumb Production demands precision and efficiency in mixing and blending equipment. The process begins with specialized mixers designed to handle large volumes while ensuring uniform distribution of ingredients. These mixers utilize advanced technologies to blend flour, water, and seasoning into a consistent dough mixture. This initial blending phase sets the foundation for the quality and texture of the final Panko breadcrumbs.

Next, the blended dough undergoes a crucial stage of shaping and cutting. Here, extrusion equipment plays a pivotal role. Extruders are equipped with precision dies that shape the dough into desired forms, whether it be traditional flake-like shapes or innovative designs tailored for specific culinary applications. This step not only defines the visual appeal of the Panko but also influences its crunchiness and overall texture.

Following shaping, the formed dough pieces are subjected to a controlled drying process. Industrial ovens with adjustable temperature and humidity settings ensure uniform drying without compromising on the crispy texture that defines premium Panko breadcrumbs. This stage requires equipment capable of handling continuous production cycles, ensuring consistent output batch after batch.

Lastly, packaging equipment completes the journey of High Production Crispy Panko Breadcrumb Production. Automated packaging lines equipped with weighing scales and sealing mechanisms efficiently package the dried breadcrumbs into various sizes and formats, ready for distribution to food manufacturers and culinary establishments worldwide. This final phase not only emphasizes efficiency but also preserves the freshness and quality of the product until it reaches the end consumer.

Quality Control in Panko Breadcrumb Production

Automated Inspection Systems: One of the cornerstones of quality control in Panko breadcrumb production is the implementation of advanced automated inspection systems. These systems utilize cutting-edge technology to meticulously examine each batch of breadcrumbs for uniformity in size, shape, and texture. By leveraging optical sensors and computer algorithms, manufacturers can swiftly detect any deviations from the desired specifications. This proactive approach not only enhances product quality but also minimizes the likelihood of defective batches reaching consumers.

Precision Monitoring of Ingredients: Another critical aspect of quality control involves the meticulous monitoring of ingredients used in the production process. High-quality Panko breadcrumbs are crafted from premium-grade ingredients that undergo rigorous testing for purity and consistency. From the selection of flour to the precise measurement of seasonings and additives, every step is meticulously controlled to uphold the desired flavor profile and texture. This meticulous attention to ingredient quality ensures that each breadcrumb produced meets the exacting standards expected in the food industry.

Stringent Hygiene Practices: Maintaining impeccable hygiene standards is non-negotiable in the production of high-production crispy Panko breadcrumbs. Industrial food machinery is routinely sanitized and maintained to prevent cross-contamination and ensure product safety. Additionally, production facilities adhere to strict protocols for personnel hygiene and gowning requirements to minimize the risk of microbial contamination. By prioritizing hygiene, manufacturers safeguard the integrity of their products and uphold consumer confidence in the safety and quality of their Panko breadcrumbs.

Continuous Process Improvement: Continuous process improvement lies at the heart of effective quality control in Panko breadcrumb production. Manufacturers regularly review and refine their production processes to optimize efficiency, reduce waste, and enhance product consistency. Through the analysis of production data and feedback mechanisms, adjustments are made to achieve tighter control over variables that impact product quality. This commitment to ongoing improvement ensures that manufacturers not only meet current quality standards but also stay ahead of evolving consumer preferences and regulatory requirements.

Safety Standards in Panko Breadcrumb Production

Safety is paramount in the realm of high production crispy Panko breadcrumb production. Industrial facilities adhere rigorously to established guidelines to ensure the integrity and safety of the production process.

Adherence to Regulatory Standards: In the production of crispy Panko breadcrumbs at scale, adherence to stringent safety standards is non-negotiable. Facilities must comply with regulations set forth by food safety authorities to maintain hygiene and prevent contamination risks. The entire process, from raw material handling to packaging, undergoes thorough scrutiny to meet these standards.

Quality Control Measures: Implementing robust quality control measures is crucial to safeguard consumer health and uphold product consistency. Advanced inspection technologies are employed throughout the production line to detect any anomalies in texture, color, or composition of the breadcrumbs. This proactive approach ensures that only top-quality crispy Panko breadcrumbs reach the market.

Employee Training and Safety Protocols: Well-trained personnel are the cornerstone of safe production practices. Workers undergo comprehensive training on equipment operation, hygiene practices, and emergency protocols. Regular safety audits and continuous improvement initiatives further enhance workplace safety, minimizing the risk of accidents and ensuring a secure environment for all staff members.

Sanitization Practices: Maintaining impeccable sanitation practices is imperative in high production environments. Equipment and production areas are routinely sanitized using approved cleaning agents to eliminate bacteria and contaminants. This meticulous attention to cleanliness not only complies with regulatory requirements but also reinforces consumer confidence in the product's safety and quality.

Innovations in High Production Panko Techniques

Innovations in technology have revolutionized the landscape of high production crispy Panko breadcrumb manufacturing, enhancing efficiency and product quality.

Automated Production Systems: Modern facilities leverage state-of-the-art automated systems to streamline the production of crispy Panko breadcrumbs. Automated mixers, conveyors, and packaging lines operate seamlessly to maximize output while maintaining consistency in texture and appearance. This integration of automation minimizes manual intervention, reduces labor costs, and accelerates throughput, meeting the demands of high-volume production.

Precision Coating Technologies: Innovations in coating technologies have optimized the application of breading to achieve the ideal crispy texture of Panko breadcrumbs. Advanced coating machines precisely distribute a uniform layer of breading onto food products, ensuring even coverage and adherence. This precision not only enhances product aesthetics but also improves frying performance, resulting in uniformly golden and crispy breadcrumbs.

Energy-Efficient Practices: Sustainability is a focal point in modern Panko breadcrumb production. Facilities are adopting energy-efficient technologies such as LED lighting, heat recovery systems, and optimized machinery designs to reduce energy consumption and environmental impact. These initiatives not only lower operational costs but also align with global sustainability goals, making the production process more eco-friendly.

Customization Capabilities: Consumer preferences drive innovation in high production Panko techniques. Manufacturers now offer customizable breadcrumb solutions tailored to specific culinary applications and dietary requirements. Whether for coating meats, seafood, or plant-based alternatives, customizable Panko breadcrumbs cater to diverse market needs, fostering culinary creativity and consumer satisfaction.

These sections provide a concise overview of safety standards and innovations in high production crispy Panko breadcrumb production, aligning with your outlined requirements.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com