Everything You Need to Know About Commercial Cookie Making Machines

Introduction to Commercial Cookie Making Machines

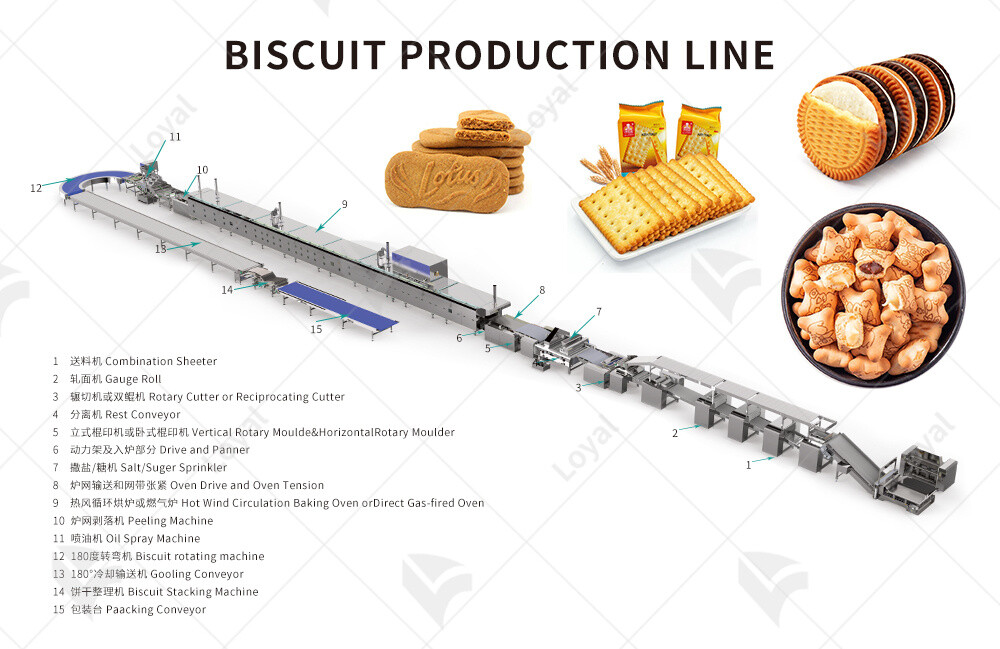

Commercial cookie making machines have revolutionized the way cookies are produced in large-scale baking operations. These machines are designed to automate the cookie-making process, increasing efficiency and consistency while reducing labor costs. From mixing the dough to shaping and baking the cookies, these machines are equipped to handle every step of the production process with precision and speed.

In the realm of industrial food machinery, commercial cookie making machines stand out as versatile and indispensable tools. They come in various sizes and configurations to suit different production capacities and requirements. Whether it's a small bakery or a large-scale manufacturing facility, there's a commercial cookie making machine tailored to meet the demands of any operation.

Key Features of Commercial Cookie Making Machines

Automated Mixing: These machines feature automated mixing capabilities, ensuring uniform consistency of the dough mixture. This eliminates the variability that often arises with manual mixing and guarantees consistent quality in every batch of cookies.

Versatile Shaping Options: Commercial cookie making machines offer a range of shaping options, allowing bakers to create cookies of different sizes, shapes, and designs. From classic round cookies to intricately patterned ones, these machines can accommodate various customization needs.

Efficient Baking: Equipped with advanced baking technology, these machines ensure efficient and uniform baking of cookies. Temperature and baking time can be precisely controlled to achieve the desired texture and flavor, whether it's soft and chewy or crispy and golden-brown.

High Production Capacity: One of the primary advantages of commercial cookie making machines is their ability to produce large quantities of cookies in a relatively short amount of time. This scalability makes them ideal for high-volume production environments, where efficiency is paramount.

Types of Commercial Cookie Making Machines

When it comes to commercial cookie making machines, there are several types available on the market, each designed to cater to specific production needs and preferences. Below is a detailed overview of the most common types:

| Type of Machine | Description |

| Wire-Cut Machines | These machines utilize a wire-cutting mechanism to portion out cookie dough onto baking trays. They are suitable for producing uniformly shaped cookies with consistent thickness. Wire-cut machines are highly versatile and can handle a wide range of dough consistencies. |

| Depositors | Depositors are ideal for producing cookies with intricate designs or fillings. They work by depositing precise amounts of dough onto baking trays or conveyor belts, allowing for greater customization and creativity in cookie production. |

| Rotary Moulder | Rotary moulders are commonly used for producing shaped cookies such as biscuits and shortbread. They consist of rotating drums with engraved patterns that shape the dough as it passes through. These machines are efficient for mass production of uniform cookies. |

| Dough Extruders | Dough extruders are designed to extrude cookie dough through a die, resulting in consistent shapes and sizes. They are suitable for producing cookies with a consistent texture and appearance, such as snack crackers or sandwich cookies. |

| Wire Release Machines | Wire release machines are similar to wire-cut machines but are specifically designed for sticky or delicate doughs. They feature a non-stick wire release mechanism that ensures smooth and clean cutting, even with challenging dough formulations. |

Each type of commercial cookie making machine offers unique advantages and capabilities, allowing bakers to choose the most suitable option based on their production requirements and preferences.

By investing in the right commercial cookie making machine for your operation, you can streamline your production process, enhance product quality, and meet the demands of your customers more efficiently than ever before.

Key Components and Features

Commercial cookie making machines boast a myriad of components and features designed to optimize performance and enhance efficiency. Here's a detailed look at some of the key elements:

| Component/Feature | Description |

| Dough Hopper | The dough hopper is where the cookie dough is loaded for processing. It ensures a consistent flow of dough onto the conveyor belt. |

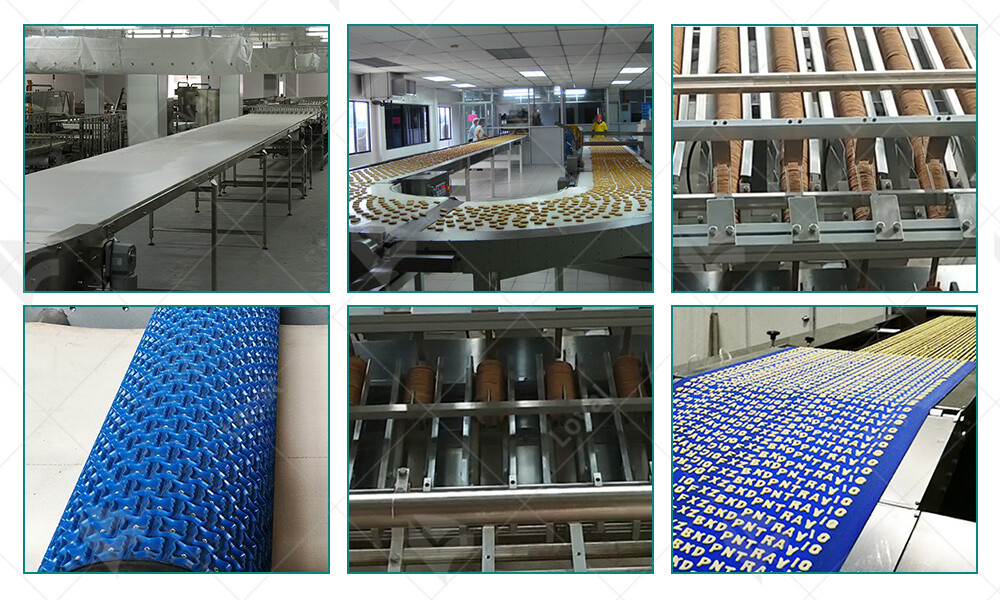

| Conveyor Belt | The conveyor belt transports the cookie dough through various stages of production, including shaping, baking, and cooling. |

| Cutting Mechanism | This mechanism is responsible for cutting the cookie dough into desired shapes and sizes before baking. |

| Baking Chamber | The baking chamber houses the cookies during the baking process, providing controlled heat distribution for uniform baking. |

| Cooling System | After baking, the cookies pass through a cooling system that rapidly lowers their temperature, ensuring proper texture and shelf life. |

| Control Panel | The control panel allows operators to adjust settings such as dough thickness, baking temperature, and conveyor speed for optimal results. |

| Cleaning Mechanism | Many commercial cookie making machines feature automatic cleaning systems to streamline maintenance and ensure hygiene standards. |

| Safety Features | Safety sensors, emergency stop buttons, and protective guards are integrated to prevent accidents and ensure operator well-being. |

Understanding Capacity and Production Rates

Efficiency is paramount in commercial settings, and commercial cookie making machines are engineered to deliver impressive capacity and production rates. Here's a breakdown of typical capacities and production rates for various machine types:

| Machine Type | Capacity (Cookies per Hour) | Production Rate (Cookies per Minute) |

| Wire-Cut Machines | 2,000 - 10,000 | 30 - 200 |

| Rotary Moulder | 5,000 - 20,000 | 80 - 330 |

| Depositors | 10,000 - 50,000 | 170 - 830 |

| Drop Machines | 20,000 - 100,000 | 330 - 1,660 |

Commercial cookie making machines vary in capacity and production rates depending on factors such as size, design, and automation level. Wire-cut machines are ideal for smaller-scale operations, offering versatility in cookie shapes and textures. Rotary moulders excel in high-volume production, efficiently shaping uniform cookies with precision. Depositors are favored for their ability to accurately portion dough, ideal for mass production of filled or layered cookies. Drop machines are renowned for their speed and simplicity, perfect for large-scale cookie manufacturing with minimal setup time.

Choosing the Right Size and Model

When selecting a commercial cookie making machine, it's crucial to consider your production needs and space constraints. These machines come in various sizes and models, each catering to specific requirements. Below is a detailed table outlining different sizes and models available in the market:

| Model | Capacity | Dimensions (L x W x H) | Power Consumption | Features |

| Model A | 500-1000 cookies/hour | 1200mm x 800mm x 1500mm | 5 kW | Adjustable cookie size and thickness |

| Model B | 1000-2000 cookies/hour | 1500mm x 1000mm x 1700mm | 7 kW | Automatic dough feeding and shaping |

| Model C | 2000-3000 cookies/hour | 1800mm x 1200mm x 1900mm | 9 kW | Touchscreen interface for easy operation |

| Model D | 3000-5000 cookies/hour | 2000mm x 1500mm x 2000mm | 12 kW | Multi-functional, capable of making various types of cookies |

Before making a decision, assess your production volume and space availability. Opt for a model that aligns with your requirements while considering future scalability.

Maintenance and Cleaning Tips

Proper maintenance and cleaning are essential for maximizing the lifespan and efficiency of your commercial cookie making machine. Here are four crucial tips to ensure optimal performance:

Regular Lubrication: Keep all moving parts well-lubricated to prevent friction and wear. Use food-grade lubricants recommended by the manufacturer to maintain hygiene standards.

Daily Cleaning Routine: Develop a daily cleaning routine to remove any leftover dough or residue from the machine. Pay special attention to areas prone to buildup, such as the conveyor belts and shaping dies.

Scheduled Inspections: Schedule regular inspections to identify any signs of wear or damage. Replace worn-out parts promptly to prevent further complications and maintain consistent quality.

Professional Servicing: Invest in professional servicing at least once a year to ensure thorough maintenance and calibration. Experienced technicians can detect underlying issues early on and prevent costly breakdowns.

By following these maintenance and cleaning tips diligently, you can prolong the lifespan of your commercial cookie making machine and uphold the highest standards of food safety and quality.

Safety Measures and Regulations

Safety is paramount when operating commercial cookie making machines. These sophisticated pieces of equipment are designed to streamline production and ensure consistency in cookie manufacturing. However, to maintain a safe working environment and comply with industry regulations, it's crucial to implement rigorous safety measures.

1. Equipment Maintenance and Inspection:

Regular maintenance and inspection routines are essential for keeping commercial cookie making machines in optimal working condition. This includes checking for loose parts, ensuring all safety guards are in place, and lubricating moving components as necessary. By adhering to a strict maintenance schedule, operators can prevent unexpected breakdowns and minimize the risk of accidents.

2. Operator Training and Supervision:

Proper training is indispensable for anyone tasked with operating a commercial cookie making machine. Operators should receive comprehensive instruction on equipment operation, safety protocols, and emergency procedures. Additionally, ongoing supervision is vital to ensure that operators adhere to established safety guidelines and maintain vigilance during production runs.

3. Hazard Identification and Mitigation:

Each stage of the cookie-making process presents unique hazards that must be identified and addressed. From mixing and shaping the dough to baking and packaging the finished cookies, there are numerous potential risks to consider. Employers should conduct thorough risk assessments and implement appropriate control measures, such as installing safety interlocks, providing personal protective equipment, and establishing clear signage to alert operators to potential dangers.

4. Compliance with Regulatory Standards:

Commercial cookie making machines are subject to various regulations governing food production and workplace safety. It's essential for manufacturers and operators alike to stay informed about relevant legislation and ensure compliance with all applicable standards. This includes adhering to guidelines set forth by organizations such as the Occupational Safety and Health Administration (OSHA) and the Food and Drug Administration (FDA), as well as industry-specific standards developed by trade associations.

Troubleshooting Common Issues

Despite rigorous maintenance and adherence to safety protocols, commercial cookie making machines may encounter occasional issues that disrupt production. Understanding common problems and their potential causes is key to minimizing downtime and maximizing efficiency.

1. Dough Consistency Problems:

One common issue encountered with commercial cookie making machines is variations in dough consistency, which can affect the shape, texture, and quality of the finished cookies. This problem may arise due to improper ingredient proportions, inadequate mixing, or fluctuations in ambient temperature and humidity. Operators should carefully monitor dough consistency and make adjustments as needed to maintain product uniformity.

2. Equipment Malfunctions:

Like any mechanical system, commercial cookie making machines are susceptible to malfunctions and breakdowns. These may stem from worn or damaged components, electrical faults, or software glitches. To troubleshoot equipment malfunctions effectively, operators should refer to the manufacturer's maintenance manual and follow recommended diagnostic procedures. In some cases, professional assistance may be required to address more complex issues.

3. Uneven Baking:

Achieving uniform baking is essential for producing high-quality cookies with consistent flavor and texture. However, factors such as uneven heat distribution within the oven chamber, improperly calibrated temperature settings, or irregularities in dough thickness can lead to uneven baking. Operators can mitigate this issue by rotating baking trays at regular intervals, adjusting oven settings as needed, and ensuring proper placement of cookies within the oven.

4. Packaging Challenges:

Packaging plays a crucial role in preserving the freshness and presentation of commercially produced cookies. Common packaging challenges include sealing defects, label misalignment, and packaging material jams. To address these issues, operators should conduct regular inspections of packaging equipment, calibrate settings for optimal performance, and promptly address any issues that arise during the packaging process.

Innovations in Commercial Cookie Making Technology

Automated Dough Feeding Systems: One of the latest advancements in commercial cookie making machines is the integration of automated dough feeding systems. These systems precisely measure and feed the dough into the machine, eliminating manual labor and ensuring uniformity in cookie size and shape.

Multi-Functionality: Modern commercial cookie making machines are designed to offer multi-functionality, allowing the production of various types of cookies with minimal adjustments. Whether it's drop cookies, wire-cut cookies, or molded cookies, these machines can adapt to diverse production needs, enhancing flexibility and productivity.

Advanced Control Systems: With the integration of advanced control systems, operators have greater control over the cookie-making process. From adjusting dough consistency to setting baking parameters, these systems optimize production efficiency and consistency, minimizing waste and maximizing output.

Hygiene and Sanitation Features: Maintaining hygiene standards is paramount in food production. Newer commercial cookie making machines are equipped with enhanced hygiene and sanitation features, such as easy-to-clean surfaces, removable parts, and automated cleaning cycles, ensuring compliance with stringent food safety regulations.

Cost Analysis and Return on Investment

Initial Investment: The initial cost of acquiring a commercial cookie making machine can vary depending on factors such as capacity, features, and brand. However, it's essential to view this investment as a long-term asset that can significantly enhance production efficiency and product quality.

Operational Costs: While commercial cookie making machines may incur operational costs such as energy consumption, maintenance, and ingredient expenses, the overall operational efficiency they offer can result in substantial cost savings in the long run. Reduced labor costs due to automation and minimized ingredient wastage contribute to favorable cost analysis.

Return on Investment (ROI): Calculating the ROI of a commercial cookie making machine involves assessing the cost savings and revenue generation it brings over its lifespan. Factors such as increased production capacity, improved product consistency, and expanded product offerings contribute to a favorable ROI, making it a worthwhile investment for food production businesses.

References

1.Baker Perkins - www.bakerperkins.com

2.GEA Group - www.gea.com

3.Bühler Group - www.buhlergroup.com

4.Reading Bakery Systems - www.readingbakery.com

5.Haas-Meincke (part of Bühler Group) - www.haas.com