Everything you Need to Know About Biscuit Manufacturing Machine

Introduction to Biscuit Manufacturing Machine

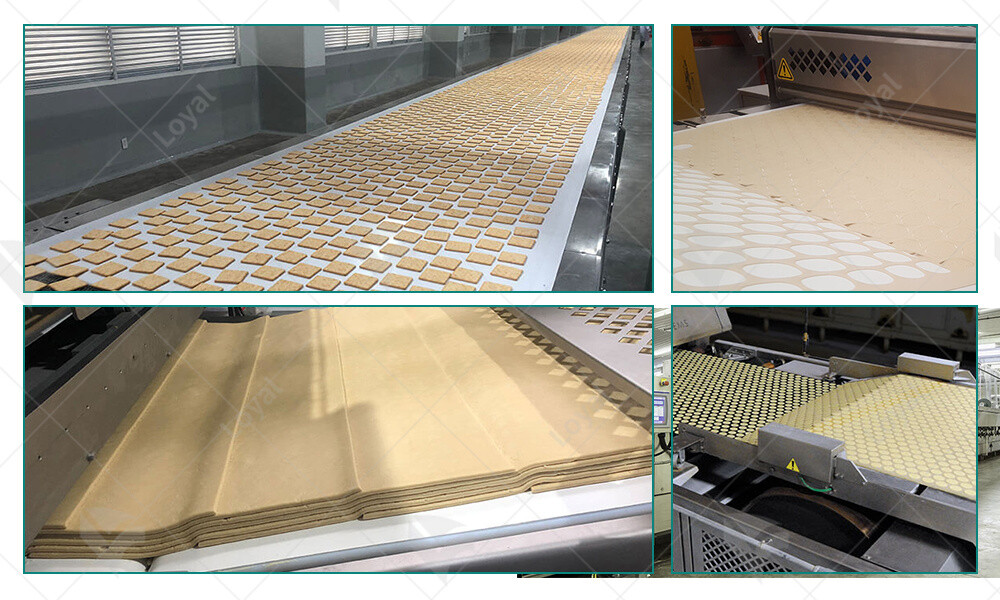

Biscuit manufacturing machines are integral components in the industrial production of biscuits. These machines are designed to automate various stages of biscuit production, from mixing and forming to baking and packaging. The biscuit manufacturing machine ensures consistency in size, shape, and quality, which is critical for meeting industry standards and consumer expectations. Utilizing advanced technology, these machines enhance efficiency, reduce labor costs, and increase production capacity, making them indispensable in modern biscuit manufacturing.

The use of biscuit manufacturing machines has revolutionized the food industry. These machines cater to a wide range of biscuit types, including hard, soft, sandwich, and specialty biscuits. By integrating precision engineering and automation, manufacturers can produce high volumes of biscuits with minimal human intervention. This not only streamlines the production process but also ensures that the end products maintain a uniform taste and texture. As consumer demand for diverse biscuit flavors and styles grows, the versatility of biscuit manufacturing machines becomes increasingly vital.

Types of Biscuit Manufacturing Machines

Machine Type | Description |

Dough Mixers | These machines blend ingredients to form a consistent dough, which is the foundation for biscuit production. They are designed to handle large volumes and ensure uniform mixing. |

Dough Feeders | Dough feeders transfer the prepared dough to the next stage of production, ensuring a continuous and efficient workflow. They help maintain consistency in dough distribution. |

Rotary Moulders | Rotary moulders shape the dough into various biscuit forms using interchangeable molds. This machine is essential for producing biscuits with intricate designs and patterns. |

Wire Cut Machines | Wire cut machines slice the dough into precise pieces, ideal for soft and sticky doughs. They ensure uniformity in biscuit size and thickness. |

Ovens | Industrial ovens bake the shaped dough to perfection. These ovens are designed for even heat distribution and temperature control, crucial for achieving the desired biscuit texture. |

Cooling Conveyors | After baking, biscuits are cooled on conveyors to stabilize their structure and prevent moisture retention. This step is vital for maintaining biscuit quality and shelf life. |

Packaging Machines | Packaging machines automate the process of wrapping and boxing the biscuits. They ensure that the final product is protected, extends shelf life, and is ready for distribution. |

Sandwiching Machines | These machines are used to apply cream or jam fillings between two biscuit layers, creating sandwich biscuits. They are precise in filling distribution and biscuit alignment. |

Decorating Machines | Decorating machines add finishing touches such as chocolate coating, icing, or sprinkles. They enhance the visual appeal and variety of the biscuits. |

Stacking and Counting Machines | These machines organize biscuits into stacks and count them before packaging. They ensure accurate quantity control and streamline the packaging process. |

Key Components of Biscuit Manufacturing Machine

A biscuit manufacturing machine is a sophisticated piece of equipment that integrates various components to ensure efficient and consistent production of biscuits. Below is a table detailing the key components of a biscuit manufacturing machine:

| Component | Description |

Dough Mixer | This component is responsible for mixing raw ingredients to form a homogeneous dough. |

Dough Feeder | Feeds the prepared dough into the machine, ensuring a continuous production process. |

Rotary Moulder | Shapes the dough into various biscuit forms using a rotary mold mechanism. |

Baking Oven | Bakes the shaped dough at precise temperatures to achieve the desired texture and flavor. |

Cooling Conveyor | Cools down the baked biscuits gradually to prevent cracking and maintain structural integrity. |

Stacker and Packer | Stacks the cooled biscuits and packs them into appropriate packaging for distribution. |

Control Panel | Centralized system to monitor and control the entire manufacturing process, ensuring efficiency. |

How Biscuit Manufacturing Machines Work

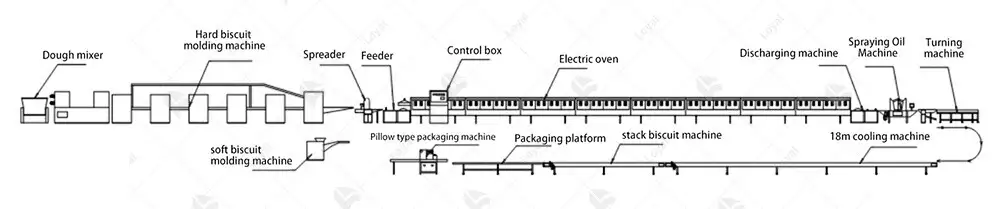

Biscuit manufacturing machines operate through a series of well-coordinated steps, each essential to producing high-quality biscuits. Here's a detailed look at the process:

Dough Preparation and Feeding The process begins with the dough mixer, where all ingredients such as flour, sugar, fat, and leavening agents are mixed to create a uniform dough. This step is critical as it ensures the consistency and quality of the biscuits. Once the dough is prepared, it is transferred to the dough feeder, which ensures a continuous and regulated flow of dough into the machine. This steady feeding is crucial for maintaining the efficiency of the production line and preventing any disruptions.

Moulding and Shaping The next stage involves the rotary moulder, a key component in shaping the biscuits. The dough passes through the rotary moulder, where it is pressed into various shapes and sizes as required by the product design. This moulding process is highly customizable, allowing manufacturers to produce a wide range of biscuit types, from simple shapes to intricate designs. The precision of the rotary moulder ensures that each biscuit is uniform in size and shape, which is important for both aesthetic appeal and packaging efficiency.

Baking and Cooling Once shaped, the biscuits move on to the baking oven. This component is vital for baking the dough to the right texture and flavor. The baking oven operates at controlled temperatures and times, which can be adjusted based on the specific requirements of different biscuit recipes. After baking, the biscuits are transferred to the cooling conveyor. This step involves gradually cooling the biscuits to room temperature. Proper cooling is essential to prevent the biscuits from cracking and to maintain their structural integrity. The cooling conveyor ensures that the biscuits are ready for the final stages of packaging without compromising their quality.

Choosing the Right Biscuit Manufacturing Machine

Selecting the appropriate biscuit manufacturing machine is critical for optimizing production efficiency and product quality. The table below highlights key considerations:

Factor | Description |

Production Capacity | Ensure the machine meets your required output volume to avoid underproduction or excessive costs. |

Automation Level | Higher automation can reduce labor costs but may require more investment upfront. |

Flexibility | A versatile machine can produce different types and shapes of biscuits, enhancing product variety. |

Energy Efficiency | Energy-efficient machines can significantly reduce operational costs over time. |

Maintenance Needs | Machines with easy maintenance requirements can minimize downtime and extend lifespan. |

Cost | Consider the total cost of ownership, including purchase price, installation, and operating expenses. |

Maintenance Tips for Biscuit Manufacturing Machines

Regular Cleaning and Inspection: Regular cleaning of the biscuit manufacturing machine is essential to prevent contamination and ensure product quality. Schedule routine inspections to identify and address wear and tear before they escalate into major issues. Focus on critical components such as rollers, cutting dies, and conveyor belts.

Lubrication and Adjustment: Proper lubrication of moving parts reduces friction and wear, extending the machine's lifespan. Regularly check and adjust settings to ensure optimal performance. Use manufacturer-recommended lubricants and follow their guidelines for frequency and quantity.

Spare Parts Management: Keep an inventory of essential spare parts to avoid prolonged downtime during repairs. This includes items like bearings, belts, and cutting tools. Establish a relationship with reliable suppliers to ensure quick access to quality parts when needed.

Operator Training: Ensure all operators are thoroughly trained in the machine's operation, safety protocols, and basic troubleshooting. Well-trained operators can identify potential problems early and perform minor repairs, reducing the need for specialized maintenance personnel.

Common Issues and Troubleshooting

Biscuit manufacturing machines, like all industrial equipment, can encounter various issues that affect their performance and output. One common problem is inconsistent dough texture, which can lead to uneven baking and poor-quality biscuits. This issue is often caused by fluctuations in ingredient measurements or improper mixing. To resolve this, it's essential to regularly calibrate the dough mixer and ensure precise ingredient weighing.

Another frequent issue is machine jamming, which can occur when dough or debris accumulates in the machine's moving parts. Regular cleaning and maintenance of the conveyor belts, rollers, and cutting mechanisms can prevent such blockages. Implementing a routine inspection schedule helps identify and address potential build-ups before they cause significant downtime.

Temperature control problems in the baking chamber can also lead to undercooked or overcooked biscuits. This can result from malfunctioning sensors or inadequate insulation. Ensuring that all temperature control systems are functioning correctly and performing regular checks on the sensors can mitigate these problems. Upgrading to more advanced control systems can also enhance precision in baking.

Lastly, wear and tear of mechanical parts is inevitable over time, leading to reduced efficiency and potential breakdowns. Regularly replacing worn-out parts and using high-quality, durable materials for components can extend the lifespan of the machine. Implementing a preventive maintenance program can catch early signs of wear, ensuring that replacements are done proactively rather than reactively.

Enhancing Efficiency in Biscuit Production

To enhance the efficiency of biscuit manufacturing, one must focus on several critical areas, starting with automation. Investing in a highly automated biscuit manufacturing machine can significantly reduce human error and increase production speed. Automated systems can handle various stages of production, from dough mixing to packaging, with minimal human intervention, thereby boosting overall efficiency.

Optimizing the production line layout is another effective strategy. A well-designed layout reduces unnecessary movement and handling of materials, streamlining the entire process. Ensuring that machines are arranged in a logical sequence that follows the natural flow of production can minimize bottlenecks and enhance throughput. Lean manufacturing principles can be applied to identify and eliminate waste in the production process.

Implementing real-time monitoring systems is crucial for maintaining efficiency. These systems provide immediate feedback on machine performance, allowing operators to make quick adjustments and address issues before they escalate. Real-time data can also be analyzed to identify patterns and predict maintenance needs, thus preventing unexpected downtime.

Finally, staff training plays a vital role in maximizing the efficiency of biscuit manufacturing. Well-trained operators can quickly troubleshoot minor issues, perform routine maintenance, and operate machines at their optimal capacity. Continuous training programs ensure that staff stay updated with the latest technological advancements and best practices in biscuit production.

Safety Guidelines for Biscuit Manufacturing Machines

Ensuring safety in the operation of a biscuit manufacturing machine is crucial for both the well-being of operators and the efficiency of production. Below is a table summarizing the key safety guidelines:

| Safety Guideline | Description |

| Training | All operators must undergo comprehensive training on the use and maintenance of the machine. This includes understanding the functions, potential hazards, and emergency procedures. |

| Personal Protective Equipment (PPE) | Operators should wear appropriate PPE such as gloves, goggles, and ear protection to prevent injuries from moving parts and loud noises. |

| Machine Guarding | Ensure all moving parts are properly guarded. Safety guards should be checked regularly for integrity and proper function. |

| Regular Maintenance | Conduct regular maintenance checks to identify and fix wear and tear, ensuring the machine operates safely and efficiently. |

| Emergency Stop Mechanisms | The machine must have easily accessible emergency stop buttons. Operators should be trained to use these in case of emergencies. |

| Cleanliness | Maintain a clean working environment to prevent slips, trips, and contamination of the product. This includes cleaning up spills and regularly sanitizing the machine. |

| Signage and Labels | Place clear and visible signs indicating potential hazards, operating instructions, and emergency procedures around the machine. |

| Electrical Safety | Ensure that all electrical components are properly insulated and grounded. Regularly inspect for exposed wires or faulty connections. |

Innovations in Biscuit Manufacturing Technology

The biscuit manufacturing machine industry has seen significant advancements in recent years, leading to enhanced efficiency, quality, and versatility in production. Here are some of the latest innovations:

Automation and Smart Technology Automation has revolutionized the biscuit manufacturing process. Modern machines are equipped with smart technology that allows for precise control over every aspect of production. From ingredient mixing to baking and packaging, automated systems ensure consistency and high-quality output. Smart sensors and AI-driven algorithms help in real-time monitoring and adjustments, reducing the likelihood of human error and improving overall efficiency.

Energy Efficiency Environmental concerns and rising energy costs have driven the development of more energy-efficient biscuit manufacturing machines. New models utilize advanced insulation materials and heat recovery systems to minimize energy consumption. These machines not only lower operational costs but also reduce the carbon footprint of biscuit production. Innovations such as variable frequency drives (VFDs) allow for better control of motor speeds, optimizing energy use during different phases of production.

Flexibility and Customization The latest biscuit manufacturing machines offer unparalleled flexibility, allowing manufacturers to produce a wide variety of biscuit types with minimal changeover time. Modular designs enable easy adjustments and quick switching between different product lines. Customizable settings for dough consistency, baking temperature, and biscuit shape mean that manufacturers can meet diverse market demands without significant downtime or reconfiguration.

Hygiene and Safety Enhancements Innovations in machine design have also focused on improving hygiene and safety. Machines now feature smoother surfaces and fewer crevices where bacteria can accumulate, making them easier to clean and maintain. The use of food-grade materials and compliance with international hygiene standards ensure that the production process is safe and sanitary. Additionally, enhanced safety features such as automated shut-off systems and improved ergonomic designs help protect operators from accidents and repetitive strain injuries.

References

1.Baker Perkins - www.bakerperkins.com

2.GEA Group - www.gea.com

3.Bühler Group - www.buhlergroup.com

4.Reading Bakery Systems - www.readingbakery.com

5.Haas-Meincke (part of Bühler Group) - www.haas.com