Everything You Need To Know About biscuit manufacturing equipment

The automatic biscuit production line is novel in design, compact in structure and high in automation.Biscuit makingmachines are designed for the mass production of biscuits in an efficient and standardized manner. They combine mechanical engineering and food technology to ensure high-quality output and consistency in biscuit size, shape, and texture. All the mechatronics of each equipment are automatically completed, and the thickness of the biscuit can be adjusted arbitrarily.

Put the mixed dough into the machine and roll it into biscuits of various shapes and weights. After baking, oil spraying and cooling, it produces golden, delicious and crisp biscuit, and the biscuit pattern can be changed according to the customer's preference. The biscuit equipment has various heating methods, including electricity, gas, heat transfer oil, etc., for customers to choose at will.

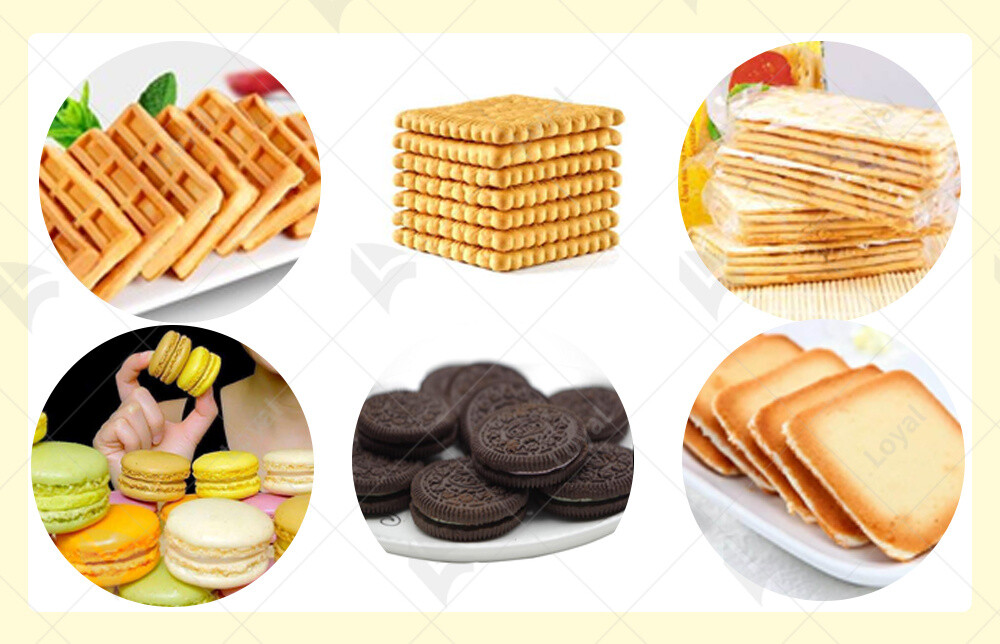

Application of Biscuit Making Machine

The biscuit making machine is suitable for all types of biscuits, such as soda biscuits, sandwich biscuits, hard biscuits, soft biscuits, printed biscuits, etc. The thickness and size of the biscuits are also adjustable so that manufacturers can make various shapes of biscuits by simply changing the mold.

The biscuit making machine is suitable for all types of biscuits, such as soda biscuits, sandwich biscuits, hard biscuits, soft biscuits, printed biscuits, etc. The thickness and size of the biscuits are also adjustable so that manufacturers can make various shapes of biscuits by simply changing the mold.

The machine is controlled by an automatic operating system and PLC touch screen, enabling continuous automatic production by simply setting parameters in advance, greatly improving production efficiency. It is also equipped with an automatic alarm system to detect system faults and reduce losses, making it one of the most popular biscuit machines on the market.

As a specialist biscuit manufacturing machine, the biscuit making machine can produce a range of high-quality biscuits, whether they are soda biscuits, chocolate sandwich biscuits, or printed biscuits. The biscuit making machine can automate the production of soda biscuits, which are very demanding and can only be produced with high-performance equipment.

Biscuit making machine can be designed with different capacities according to customer requirements, enabling individual customization to meet manufacturers' different needs. The machine is also one of the most popular machines thanks to its high quality and competitive price.

The biscuit making machine adopts advanced technology at home and abroad, uses the best quality food-grade materials. It is equipped with various models, allowing manufacturers to produce various types of chocolate sandwich biscuits, hard biscuits, and soda biscuits according to market demand. The machine has mature technology, and the control and operation of key components are more accurate and safer. Meanwhile, manufacturers can provide perfect after-sales service, making it a highly sought-after quality machine for all major biscuit manufacturers.

The Fully Automatic Biscuit Making Machines is for chocolate deposit forming. The whole process is fully automatic including depositing, mould plate vibrating, cooling, demoulding, conveying and plate heating. You can choose one head semi-automatic, one head, two heads or three heads moulding line for different products. The line is suitable for pure chocolate, center filled chocolate, two colors chocolate, four color chocolate, amber or agate chocolate, etc.

PRODUCTION PROCESS, STEPS, AND COMPOSITION STRUCTURE

Process flow: Flour Mixer→Shaping&Cutting→Controller→Baking Oven→Spraying Oil→Cooling→Packing

First, we need to prepare all the ingredients and flour, follow the recipe to ensure the exact amount of ingredients, and then place these ingredients in the Dough Maker to be mixed.

The next formed dough will go into the Compound Rolling and Shaping Machine, including roll printing and roll cutting, and then creating various shapes of biscuits according to the machine model.

Once the biscuit shapes are made, the biscuits will go into the baking oven.

Then the biscuits go to the Oiling Sprayer for flavoring and oiling.

After oil spraying, the biscuits enter the Cooling Machine.

Finally, put the biscuits into the package.

| Advantage Of Biscuit Making Machine | |

| 1 | The Biscuit Machine Occupies a Small Area And Consumes Less, Small Workshop Can Also Start Production Easily. |

| 2 | Biscuit Machine There Are Many Types Of Molds And Product Designs. One Machine Can Produce Crispy Biscuits, Tough Biscuits, Chocolate Biscuits, Such As Cream Biscuits, Sandwich Biscuits, Soda Biscuits, Animal Biscuits, Vegetable Biscuits |

| Biscuit Making Machine Can Produce 24 Hours Continuously Every Day. | |

| 3 | Fully Automatic Small Biscuit Machine Requires Fewer Workers, 2-3 Workers Can Complete The Whole Process From Raw Material Mixing To Packaging, |

| The Operation Is Simple, And The Workers Can Easily Operate The Machine After Training. | |

| 4 | No Industrial Pollution And No Waste. |

How do you make grand biscuits?

Now the most popular snack foods must have a place for biscuits. After the changes of the times, biscuits have evolved into many different types, such as chocolate biscuits, cookies, sandwich biscuits and soda biscuits. There are people who love them, from the elderly to the three-year-old children, all have a unique love for biscuits.

Nowadays, the improvement of living standards has also caused people to pay attention to the cultivation of hobbies. Many people regard baking as a hobby. The biscuits made by themselves are always exceptionally delicious. Do you know how to make biscuits?

The professional technical article in the top ten biscuit production lines in 2021 shows that making biscuits is a very fulfilling thing. It can not only improve the hands-on ability and make our lives more colorful, but also eat safer and more secure biscuits. The steps of making biscuits are also relatively simple. After kneading, cutting, and baking, the production can be completed.

When making biscuits, in order to ensure the quality and efficiency of biscuits production, the manufacturer usually uses the Biscuit Production Line for production. This equipment is recognized by the manufacturer as a high-quality equipment.

Biscuit Production Line has reached the world's leading level and has a very high cost performance.Using a fully automatic PLC control system, stable production and high production efficiency. The stainless steel parts are clean and hygienic, easy to clean and durable. We can produce many types of biscuits. We can also customize molds according to your requirements. We also provide services such as warranty and installation instructions to escort your production.

Biscuit production is a very important part of the food processing industry.

Biscuit Process Line - Biscuits From Scratch With Flow Chart:

The Fully Automatic biscuit production line includes 1 dough mixer, 1 molding head, a 10-meter oven (5 sections), a 2-meter cooling line, 1 distribution box, 2 machine-belt molds, and a total length of 16 meters. The total power is 35KW, the volume is 10 cubic meters, and the weight is about 1 ton. The output is 50 to 60 kg per hour.

1.Mixing Material

Mixing the raw material of flour ,sugar,together.

2.Shaping:

Add the prepared dough to the feeding hopper of the rolling and cutting biscuit form machine. Under the carrying and squeezing of the feed trough roller. The material enters the mold of the roll and be compacted.

Form a relatively neat bottom surface of the biscuit blank. As the mold roll rotates further downward. The biscuit blank touches the horizontal canvas conveyor belt. And release from the mold under the action of rubber release roller.

The biscuit can be different shape and pattern,different size

By changing the machine molds.such as round,square,heart,triangle.flower,etc.

3.Baking :

Because the Soft biscuit formula contains more oil and sugar. There is less binding in the dough. Therefore, the moisture in the dough easily evaporates. Then the baking process of crispy biscuits often adopts the "higher temperature. shorter baking time" baking process.In actual production. The appropriate baking temperature will be depend on the hardness,size of the biscuit blank .Generally speaking. The temperature in the front area of the oven is 250~280℃. The temperature in the central zone is 220~240℃. The temperature in the rear zone is 180~200℃. At this baking temperature. The baking time is 5 to 6 minutes.

4.Oil Spraying

Spraying oil on the surface of the baked biscuit to make biscuit more beautiful and delicious,

5.Cooling

The surface temperature of the biscuits when they are just out of the oven can reach 180℃, and the temperature of the center layer is about 110℃, which must be cooled to 38~40℃. Due to the low content of sugar and fat in the ingredients and the large pores in the biscuits, hard biscuits are prone to cracking and cracking of the finished product. During the cooling process, forced ventilation cannot be used to prevent the temperature from falling too fast and the transportation environment being too dry. The product is broken during storage and requires complete cooling, as low as possible at room temperature.

6.Packing

The last step was packing,it can adopt small bag packing

Parts of Biscuit Process Line :

The whole cookies production line is composed of a variety of equipment, manufacturers can choose combined equipment or an individual one, it’s very flexible.

Cookies Dough mixer: Mix all the ingredients evenly and knead them into a smooth dough.

Cookies Forming machine: The dough will be rolled into a certain shape in this equipment, and the biscuit is preliminarily formed.

CookiesBaking oven: Bake biscuits at high temperature and the biscuit is easily get done, meanwhile the biscuit is tastier.

Oil spraying machine: spray a layer of oil mist on the surface of biscuits to make them more outstanding in color and flavor.

Cookies Cooling machine: cool biscuits quickly. So the biscuit at regular temperature won’t become soggy after packaging and have a longer shelf life..

Cookies Packaging machine: fully automatic packaging, bag-making, and weighing are completed automatically. Makes it easy to seal the edge and make

high-quality biscuits

Biscuit Production Line Flow :

Pretreatment Of Raw Materials - Dough Preparation - Rolling Dough Sheet - Pressing Into Cake Base - Baking - Oil Spraying – Cooling

Benefits of Biscuit Production Line :

The automatic cookie production line has a large output, which can guarantee the market demand.

The cookie process technology in the production and manufacturing workshop is advanced, stable and reliable, and can be kept basically unchanged for a longer period of time.

Full-automatic cookie equipment to reduce the production area.

Improve labor productivity, stabilize and improve product quality.

Small biscuit process line technical parameter:

| Item No. | Capacity(kg/h) | Heating type |

| LY-25-I | 40-50kg/h | Electricity,Gas,Diesel |

| LY-25-II | 50-100kg/h | Electricity,Gas,Diesel |

| LY-320 | 100-150kg/h | Electricity,Gas,Diesel |

Automatic biscuit process line technical parameter:

| Item No. | Capacity(kg/h) | Heating type |

| LY-400 | 150-200kg/h | Electricity,Gas,Diesel |

| LY-600 | 400-500kg/h | Electricity,Gas,Diesel |

| LY-800 | 600-800kg/h | Electricity,Gas,Diesel |

| LY-1000 | 1000kg/h | Electricity,Gas,Diesel |

| LY-1200 | 2000kg/h | Electricity,Gas,Diesel |

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/