Everything you need to know about biscuit machine production line In 2024

Introduction

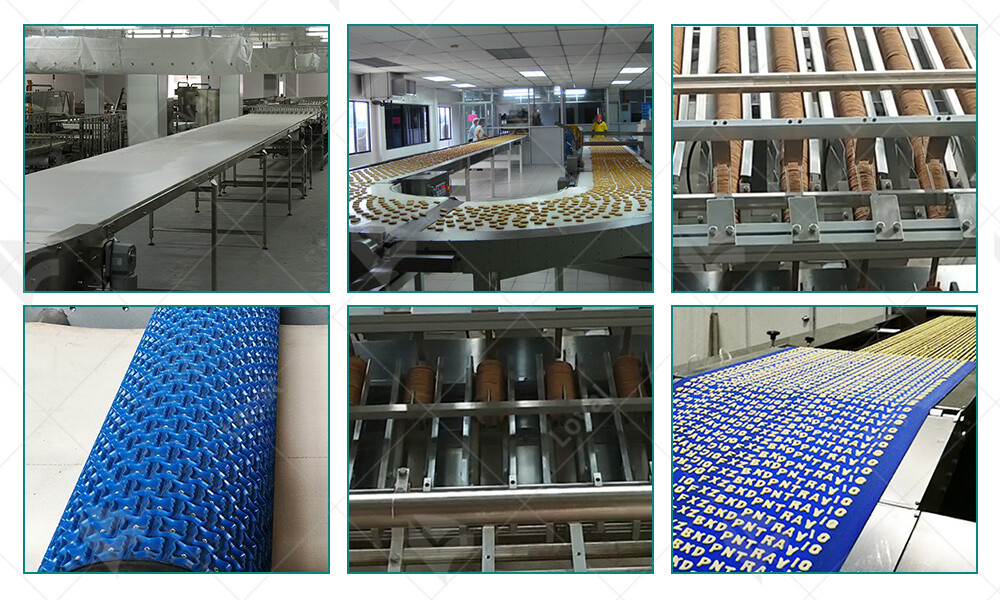

Biscuit machines, also known as cookie makers, are sophisticated pieces of equipment essential in the modern food industry. These machines automate various stages of the biscuit-making process, enhancing efficiency, consistency, and quality. In this guide, we'll delve into the importance of biscuit machines in the food industry, exploring their role in streamlining production processes and ensuring the production of high-quality biscuits and cookies.

Biscuit machines are the cornerstone of modern biscuit and cookie production, revolutionizing the industry with their precision and efficiency. These sophisticated machines automate the biscuit-making process, ensuring consistency and quality in every batch. From mixing dough to shaping, baking, and packaging, biscuit machines streamline production, meeting the growing demand for biscuits and cookies worldwide. Join us as we explore the pivotal role of biscuit machines in shaping the future of food manufacturing.

Types of Biscuit Machines

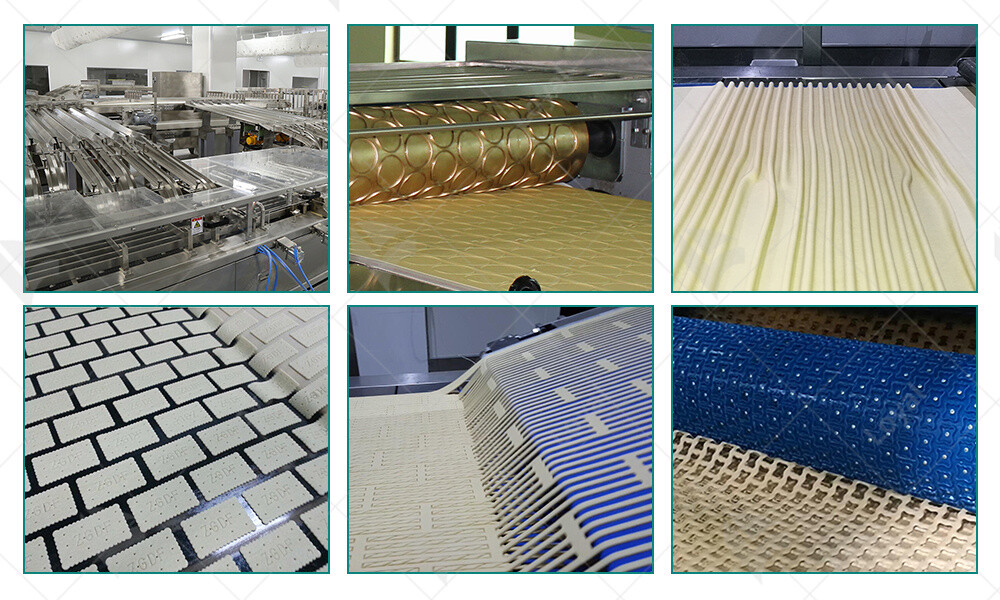

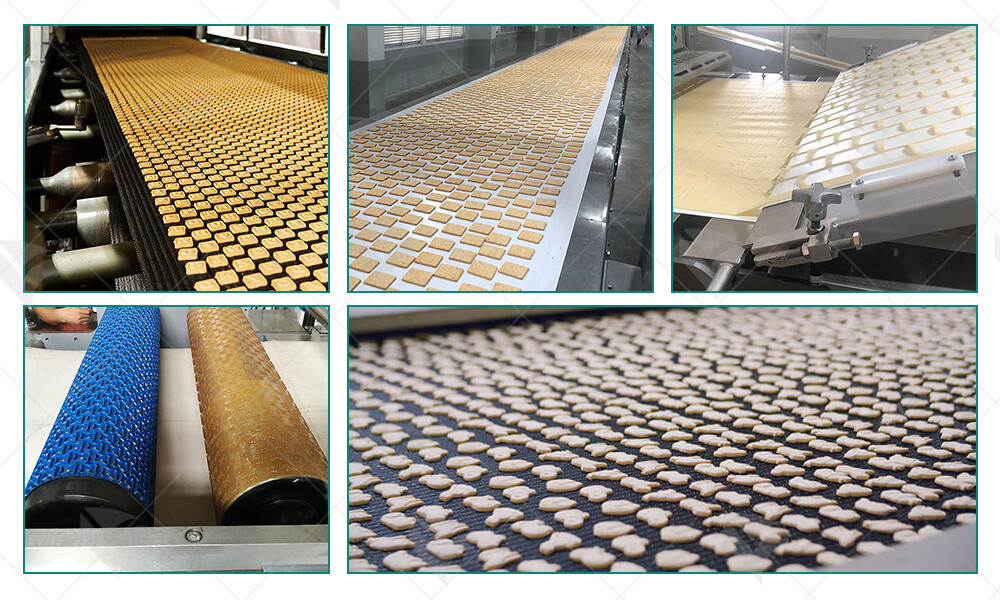

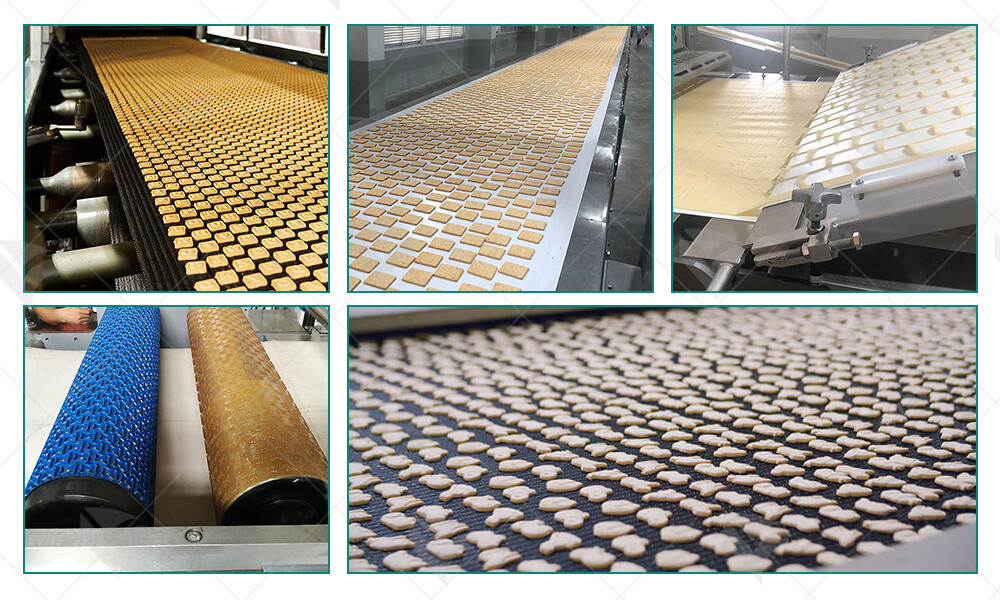

In the dynamic landscape of biscuit manufacturing, a variety of biscuit machines cater to different production needs. These machines encompass a range of functionalities, each tailored to specific stages of the biscuit-making process. Let's explore the diverse types of biscuit machines available in 2024:

1.Rotary Moulder: This machine is adept at shaping dough into consistent shapes and sizes, ideal for biscuits with intricate designs or patterns.

2.Wire-Cut Depositor: Designed for precision, this machine deposits accurately portioned dough onto baking trays, perfect for biscuits with irregular shapes or sizes.

3.Dough Sheeter: Utilizing rollers to flatten dough to uniform thickness, this machine ensures consistency in dough preparation for various biscuit types.

4.Biscuit Oven: The heart of the biscuit-making process, this machine bakes dough into crispy, golden biscuits, with precise temperature and humidity control for optimal results.

Each type of biscuit machine plays a crucial role in the production line, contributing to the efficiency, consistency, and quality of biscuits produced. As technology advances, these machines continue to evolve, driving innovation and shaping the future of biscuit manufacturing.

Factors to Consider When Choosing a Biscuit Machine

Selecting the right biscuit machine is a critical decision for biscuit manufacturers, impacting production efficiency, product quality, and overall profitability. Several key factors must be carefully considered to ensure that the chosen machine aligns with specific production needs and business objectives:

Production Capacity: One of the primary considerations when choosing a biscuit machine is its production capacity. Manufacturers must assess their current and projected production volumes to determine the appropriate machine size and capability. Investing in a machine with the right capacity ensures that production demands can be met efficiently without overstretching resources or underutilizing capacity.

Space Requirements: Another important factor to consider is the available space in the production facility. Biscuit machines come in various sizes and configurations, and it's essential to ensure that the chosen machine can be accommodated within the existing space constraints. Additionally, consideration should be given to factors such as access for maintenance and operational workflow to optimize space utilization.

Budget Constraints: Budget considerations play a significant role in the selection process. Manufacturers must balance their desired features and capabilities with their budgetary constraints to make a cost-effective investment. While it may be tempting to opt for the most advanced and feature-rich machine available, it's essential to prioritize features that align with production needs and offer the best return on investment.

Reliability and Durability: The reliability and durability of a biscuit machine are critical factors that directly impact long-term operational success. Choosing a reputable manufacturer known for producing reliable and durable machines can minimize the risk of unexpected downtime and maintenance costs. Additionally, carefully evaluating the build quality, materials, and engineering of the machine can provide insight into its longevity and performance under heavy usage.

Ease of Maintenance: Maintenance requirements should also be considered when selecting a biscuit machine. Machines that are easy to maintain and service can help minimize downtime and ensure consistent performance. Factors such as accessibility of components, ease of cleaning, and availability of spare parts should be evaluated to determine the machine's overall maintenance requirements.

By carefully considering these factors and conducting thorough research, biscuit manufacturers can make informed decisions when choosing a biscuit machine that meets their specific production needs, budgetary constraints, and long-term goals. Ultimately, investing in the right biscuit machine can drive operational efficiency, enhance product quality, and contribute to the overall success of the manufacturing operation.

Selecting the right biscuit machine is a pivotal decision for biscuit manufacturers, impacting production efficiency and product quality. Several factors must be considered to ensure the chosen machine aligns with specific production needs:

Latest Technological Advancements in Biscuit Machines

Innovation is the driving force behind advancements in biscuit machine technology. Manufacturers continually strive to incorporate cutting-edge features to enhance efficiency, precision, and product quality. Some of the latest technological advancements in biscuit machines include:

1. Automation: Integration of advanced automation systems streamlines production processes, reducing manual labor and enhancing consistency.

2. Robotics: Implementation of robotics improves handling and packaging operations, increasing efficiency and reducing human error.

3. IoT (Internet of Things): Connectivity and data analytics capabilities enable real-time monitoring of machine performance, predictive maintenance, and optimization of production parameters.

4. Energy Efficiency: Adoption of energy-efficient components and systems reduces energy consumption, contributing to sustainability and cost savings.

By leveraging these technological advancements, biscuit manufacturers can stay competitive, meet evolving consumer demands, and drive innovation in the industry.

Maintenance and Troubleshooting Tips for Biscuit Machines

Effective maintenance is essential to ensure optimal performance and longevity of biscuit machines. Implementing regular maintenance routines and troubleshooting techniques can prevent downtime and minimize disruptions in production. Here are some key maintenance and troubleshooting tips for biscuit machines:

1. Regular Cleaning: Keep the machine clean by removing crumbs, debris, and residue to prevent buildup and ensure hygiene.

2. Lubrication: Apply lubricants to moving parts according to manufacturer recommendations to reduce friction and prevent wear.

3. Inspection: Regularly inspect machine components for signs of wear, damage, or misalignment, and address issues promptly to prevent further damage.

4. Calibration: Calibrate sensors, controls, and settings regularly to maintain accuracy and consistency in production processes.

5. Training: Provide comprehensive training to operators on proper machine operation, maintenance procedures, and troubleshooting techniques to ensure optimal performance.

By following these maintenance and troubleshooting tips, biscuit manufacturers can prolong the lifespan of their machines, minimize downtime, and maximize productivity.

The Importance of Biscuit Machines

Biscuit machines stand as the cornerstone of modern biscuit manufacturing, playing a pivotal role in shaping the efficiency, quality, and profitability of the industry. Their importance lies in their ability to automate and streamline the biscuit-making process, ensuring consistency and precision at every stage of production.

At the heart of their significance is the enhancement of production efficiency. Biscuit machines automate tasks that were once labor-intensive, such as dough mixing, shaping, baking, and packaging. This automation not only increases productivity but also reduces the reliance on manual labor, leading to cost savings and improved resource utilization.

Furthermore, biscuit machines play a crucial role in maintaining product quality and consistency. Equipped with advanced controls and mechanisms, these machines ensure uniformity in dough thickness, shape, and baking, resulting in biscuits that meet stringent quality standards. Consistency is key in building consumer trust and loyalty, as customers expect the same level of taste and texture with every purchase.

Moreover, biscuit machines enable manufacturers to meet the ever-growing demand for biscuits in the market. As consumer preferences evolve and global populations increase, the need for efficient and scalable production solutions becomes paramount. Biscuit machines rise to the occasion, allowing manufacturers to ramp up production while maintaining high standards of quality and consistency.

In summary, the importance of biscuit machines in the food industry cannot be overstated. They drive efficiency, consistency, and innovation in biscuit manufacturing, ensuring that consumers can enjoy high-quality biscuits with every bite. As technology continues to advance, biscuit machines will continue to play a vital role in shaping the future of the industry.

Future Trends and Innovations in Biscuit Making Technology

Looking ahead, the future of biscuit making technology is ripe with promising advancements and innovations. Here are some key trends shaping the landscape of biscuit manufacturing:

1. 3D Printing: The emergence of 3D printing technology offers exciting possibilities for creating intricately designed biscuits with customizable shapes and patterns. This innovation opens up new avenues for creativity and personalization in biscuit production.

2. Sustainable Packaging: With increasing awareness of environmental issues, biscuit manufacturers are exploring sustainable packaging solutions. Biodegradable and compostable packaging materials are becoming increasingly popular, aligning with consumer preferences for eco-friendly products.

3. Smart Manufacturing: The integration of IoT (Internet of Things) technology enables real-time monitoring and optimization of production processes. Smart sensors collect data on machine performance and product quality, allowing manufacturers to make informed decisions and maximize efficiency.

4. Personalized Nutrition: As consumers become more health-conscious, there is a growing demand for biscuits tailored to individual dietary preferences and nutritional needs. Biscuit machines equipped with technology for personalized nutrition formulation can cater to this demand, offering customized biscuit options.

5. Automation and Robotics: Continued advancements in automation and robotics streamline production processes further, reducing labor costs and improving efficiency. Robots equipped with AI (Artificial Intelligence) can perform tasks such as sorting, packaging, and quality control with precision and speed.

These trends and innovations are poised to reshape the biscuit manufacturing industry, driving efficiency, sustainability, and consumer satisfaction. By embracing these advancements, biscuit manufacturers can stay ahead of the curve and meet the evolving demands of the market.

Regulations and Compliance in Biscuit Manufacturing

Ensuring regulatory compliance is a cornerstone of biscuit manufacturing, guaranteeing product safety and consumer confidence. Here's a closer look at key areas of regulation:

Food Safety Standards: Strict adherence to food safety regulations like HACCP and FDA guidelines is essential. These regulations govern every aspect of production, from ingredient sourcing to packaging, to prevent contamination and ensure the safety of the final product.

Quality Assurance: Meeting industry standards such as ISO 22000 and BRC Global Standards for Food Safety demonstrates a commitment to quality. Compliance involves rigorous quality control measures at every stage of production to maintain consistency and integrity.

Labeling Requirements: Accurate and comprehensive labeling is crucial to inform consumers about ingredients, allergens, and nutritional information. Compliance with labeling regulations, such as FDA requirements in the US and EU regulations in Europe, ensures transparency and consumer safety.

Hygiene Practices: Implementing robust hygiene protocols is paramount to prevent cross-contamination and maintain sanitary conditions in the production facility. Regular equipment cleaning, sanitation procedures, and employee training are essential components of effective hygiene practices.

Environmental Responsibility: Biscuit manufacturers must also comply with environmental regulations to minimize their ecological footprint. This includes proper waste management, energy efficiency measures, and sustainable sourcing practices to reduce environmental impact.

By prioritizing regulatory compliance across these areas, biscuit manufacturers can uphold food safety standards, maintain product quality, and earn the trust of consumers and regulatory authorities alike.

Conclusion: The Role of Biscuit Machines in Shaping the Future of Food Industry

In conclusion, biscuit machines play a pivotal role in shaping the future of the food industry by driving efficiency, innovation, and sustainability. As we've explored throughout this guide, these sophisticated pieces of equipment automate and streamline the biscuit-making process, ensuring consistency and quality in every batch of biscuits produced.

From mixing and shaping to baking and packaging, biscuit machines optimize production processes, enabling manufacturers to meet the growing demand for biscuits while maintaining high standards of quality and efficiency. Moreover, advancements in technology, such as automation, robotics, and IoT integration, continue to push the boundaries of what is possible in biscuit manufacturing, driving further improvements in productivity and product customization.

Furthermore, biscuit machines play a crucial role in ensuring compliance with regulatory standards and food safety regulations, safeguarding consumer health and trust. By adhering to stringent hygiene practices and quality assurance measures, biscuit manufacturers can uphold their reputation for delivering safe and high-quality products to consumers.

Looking ahead, the future of biscuit machines is promising, with ongoing advancements in technology and a growing focus on sustainability and environmental responsibility. By embracing these trends and innovations, biscuit manufacturers can stay ahead of the curve, meet evolving consumer demands, and contribute to the continued growth and development of the food industry.

In essence, biscuit machines are not just tools of production; they are the driving force behind progress and innovation in biscuit manufacturing, shaping the future of the food industry one delicious biscuit at a time.

Reference

1. Food Engineering Magazine:https://www.foodengineeringmag.com/

2. Food Processing Magazine :https://www.foodprocessing.com/

3. Packaging World:https://www.packworld.com/

4. Processing Magazine:https://www.processingmagazine.com/

5. Food Manufacture:https://www.foodmanufacture.co.uk/