Application

Do you know how pet food is produced

Do you know how pet food is produced?

Introduction of pet food:

The pet feed market is an ever-expanding market. As people's attention and requirements for pet care increase, the demand for pet feed is also growing year by year.

Pet feed on the market is mainly divided into dog food, cat food and other small animal feed. Among them, dog food and cat food are the two main categories.

Depending on the age, breed and special needs of different pets, there are various pet feeds available on the market, such as puppy/kitten feed, adult dog/cat feed, aging dog/aging cat feed, and special flavor feed wait. These pet feeds are often positioned and sold based on their product benefits, such as enhancing immunity, promoting digestion, improving hair quality, etc.

In addition, as people's living standards improve and their care for pets increases, some high-end pet feed brands have gradually emerged. These high-end brands usually focus on the nutritional ingredient ratio of pet food, the quality and traceability of raw materials, and the advancement of production processes.

Competition in the pet feed market is fierce, with numerous brands and vast space for consumers to choose. Manufacturers can attract consumers' attention and purchases by continuously improving product quality, launching innovative products and services, and strengthening brand promotion and marketing.

According to market research reports, the global pet food market is growing and is expected to maintain a stable growth trend in the next few years. This also brings good business opportunities and development prospects to pet feed manufacturers.

Introduction to pet feed production line:

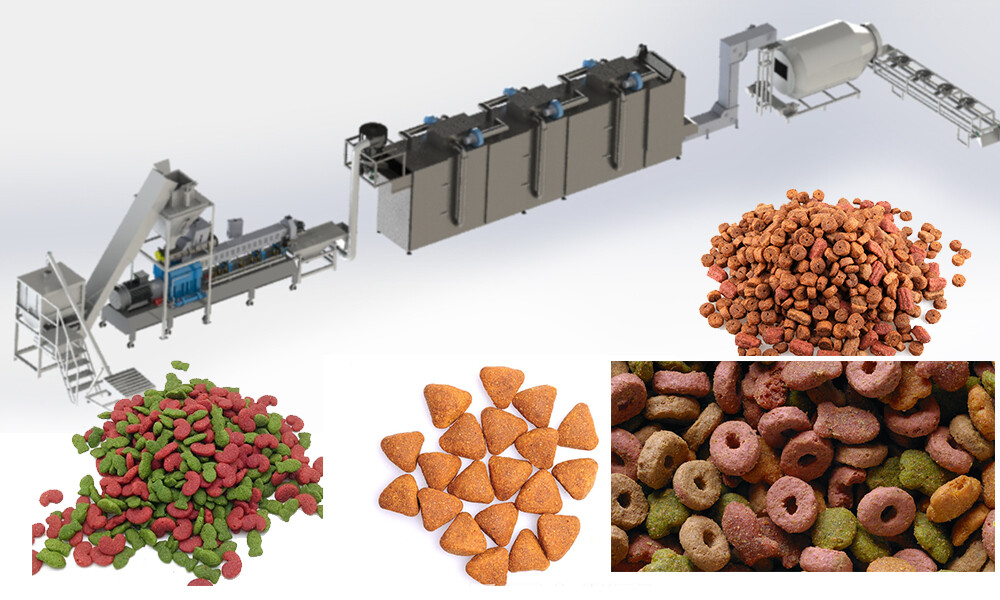

The pet feed production line is an equipment system specially used to produce pet food. It is composed of a series of mechanical equipment, mainly including: powder mixing machine - screw conveyor - twin-screw extruder - air conveyor - oven - automatic seasoning line.

First of all, raw material processing equipment is used to process raw materials, including main ingredients such as grains, meat, fish, vegetables, etc., as well as additives such as vitamins, minerals, etc. After these raw materials are cleaned, ground, mixed, etc., a uniform mixture of raw materials is obtained.

Next, the mixing equipment uniformly mixes the raw material mixture to ensure that the various ingredients are evenly distributed, thereby improving the quality and taste of the food.

Then, the mixed raw material mixture is sent to the granulation equipment, and through mechanical processes such as extrusion and cutting, it is made into granular pet food.

Pet food made into granules needs to be dried by drying equipment to remove excess moisture and improve the preservation and taste of the food.

Finally, the packaging equipment packages the dried pet food, usually in plastic bags, cans, etc., for easy storage and sales.

Pet feed production lines are often customized based on specific needs to accommodate different sizes and types of pet food production. At the same time, the degree of automation of the production line can also be adjusted according to needs, with various equipment configurations from semi-automatic to fully automatic to improve production efficiency and quality control capabilities.

The use of pet feed production lines can greatly improve production efficiency and product quality, and can meet the needs of different pet food markets. This also provides pet feed manufacturers with better production conditions and profit margins.

Machine material | stainless steel |

Machine weight | 1000Kg |

Delivery time | 25-30 days |

Whether to accept customization | Yes |

Factory inspection video | provided |

Warranty | one year |

Installing the machine | Our company will send engineers |

The future of the pet market is very good now. If you buy it as soon as possible, you can make money as soon as possible!