Discovering The World Of Puff Snacks Food Extruder

Introduction to Puff Snacks Food Extruder

The Puff Snacks Food Extruder stands as a cornerstone of modern snack manufacturing, revolutionizing how producers transform raw ingredients into light, crispy, and irresistibly crunchy puffed snacks. At its core, this specialized machinery operates on the principle of thermomechanical processing, combining heat, pressure, and mechanical shear to cook, shape, and expand grain-based materials into iconic snack forms such as corn puffs, cheese curls, and rice-based treats. Historically rooted in mid-20th-century advancements in food engineering, early extruders relied on single-screw designs to process basic cornmeal or rice blends. However, rapid industrialization and evolving consumer preferences for convenience snacks spurred continuous innovation, leading to today’s high-efficiency, automated Puff Snacks Food Extruders capable of handling diverse raw materials—from traditional cereal grains to alternative ingredients like pulses, ancient grains, and plant-based proteins. These machines now dominate global snack production lines, driving an industry valued at billions annually by enabling manufacturers to meet skyrocketing demand for on-the-go, flavor-forward snacks while maintaining strict quality and efficiency standards.

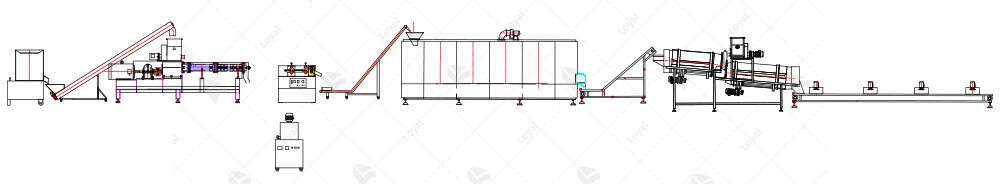

Core Components and Mechanics of Puff Snacks Food Extruder

The Puff Snacks Food Extruder stands as a cornerstone of modern snack manufacturing, transforming raw agricultural commodities into crispy, airy, and consumer-friendly puffed snacks. Understanding its core components and operational mechanics is essential for optimizing production efficiency, product quality, and innovation in the rapidly evolving snack industry.

1.1 Key Components of a Puff Snacks Food Extruder

The extruder’s design integrates multiple interdependent systems, each critical to the final product’s texture, flavor, and appearance.

Barrel and Screw Assembly:The extruder’s barrel serves as the primary reaction vessel, where raw materials (e.g., corn, rice, wheat, or potato starch) undergo thermal, mechanical, and hydrodynamic transformations. Inside the barrel, a rotating screw (or twin screws in advanced models) propels materials forward while applying shear forces and pressure.

Single-Screw vs. Twin-Screw Designs: Single-screw extruders are simpler and cost-effective for basic puffed snacks, while twin-screw extruders offer superior mixing, heat transfer, and control over product expansion. Twin-screw systems are particularly advantageous for co-extrusion (e.g., layered snacks with filling) or high-moisture formulations.

Screw Geometry: The screw’s pitch, flight depth, and compression ratio dictate material flow, residence time, and energy input. Shorter flight depths and higher compression zones near the die enhance puffing by building pressure before sudden expansion.

Die and Cutting System:The die, located at the barrel’s exit, shapes the molten extrudate into desired forms (e.g., stars, tubes, or rings). Its design influences:

Expansion Rate: Aperture size and shape affect steam release during extrusion, determining the snack’s porosity and crunch.

Surface Texture: Grooved or patterned dies can create visual appeal (e.g., ridged potato chips).The cutting system, typically a rotating knife or wire die, synchronizes with the extrudate’s exit speed to ensure uniform snack length and prevent deformation.

Heating and Cooling Systems:Extruders rely on precise temperature control to activate starch gelatinization, protein denaturation, and steam-driven expansion.

Barrel Zoning: Multi-zone heating (via electrical resistance, steam, or infrared) allows staged temperature adjustments, from 40°C (for moisture management) to 180°C (for Maillard reactions).

Post-Extrusion Cooling: Air-knife systems or water baths rapidly solidify the extrudate, locking in texture and preventing collapse.

1.2 The Extrusion Process: From Raw Material to Puffed Snack

The Puff Snacks Food Extruder operates through a series of interconnected thermodynamic and mechanical stages:

Feeding and Preconditioning:Dry ingredients (e.g., flour, salt, seasonings) are mixed with water or steam in a preconditioner to achieve 12–18% moisture content. This step enhances starch plasticity and reduces screw wear.

Compression and Shearing:As materials move through the screw’s compression zone, pressure builds (up to 30 bar), forcing steam generation from residual moisture. Shear forces align starch molecules, creating a viscoelastic melt.

Die Expansion (Puffing):The sudden pressure drop at the die triggers rapid steam expansion, causing the extrudate to swell 2–5 times its original volume. This process, known as “flash expansion,” creates the snack’s characteristic porous structure.

Drying and Toasting (Optional):Some extrudates undergo post-extrusion drying (e.g., fluidized beds) to reduce moisture to 2–4% for shelf stability. Toasting ovens may add color and flavor via the Maillard reaction.

1.3 Technological Advancements in Extruder Design

Modern Puff Snacks Food Extruders leverage innovations to improve versatility and sustainability:

Co-Extrusion Technology:Allows simultaneous extrusion of two materials (e.g., a crunchy shell and creamy filling) through concentric dies, enabling products like cheese-filled puffs or chocolate-coated snacks.

Cold Extrusion for Healthier Snacks:Low-temperature processes preserve nutrients and antioxidants in ingredients like legumes or whole grains, appealing to health-conscious consumers.

Energy-Efficient Systems:Variable-speed drives, heat recovery units, and insulated barrels reduce energy consumption by up to 30% compared to traditional designs.

Types of Puff Snacks Produced by Food Extruders

The versatility of the Puff Snacks Food Extruder lies in its ability to transform basic raw materials into an array of snack products, each with distinct textures, flavors, and shapes. Below is a structured breakdown of the most common puff snack categories and the extrusion-driven innovations shaping their production.

3.1 Common Snack Categories

The Puff Snacks Food Extruder excels in producing staple snack varieties that dominate global markets:

Corn Puffs: A classic example of single-screw extrusion, corn grits are cooked under high pressure and temperature, causing rapid expansion into airy, hollow structures. Popular brands like Cheetos and Pirate’s Booty rely on this process.

Cheese Curls: These are typically co-extruded snacks, where a cheese-flavored paste is encased within a corn or potato-based shell. The Puff Snacks Food Extruder’s dual-layer extrusion capability ensures crispness and flavor burst in every bite.

Rice Cakes: Made from puffed rice grains, these snacks leverage the extruder’s low-moisture, high-temperature environment to create lightweight, crunchy discs. Modern extruders now support multigrain blends (e.g., brown rice, quinoa) for health-conscious consumers.

Multigrain Snacks: Combining oats, barley, or legumes with corn or wheat, these snacks are tailored for the "better-for-you" market. The Puff Snacks Food Extruder’s precision in controlling temperature and shear forces preserves nutritional integrity while achieving ideal puffing.

3.2 Texture and Flavor Variations

The Puff Snacks Food Extruder enables manufacturers to experiment with sensory attributes that appeal to diverse consumer preferences:

Crunchy vs. Airy Textures: Adjusting screw speed, barrel temperature, and die geometry allows producers to toggle between dense, crunchy bites (e.g., crackers) and ultra-light, melt-in-the-mouth puffs (e.g., cheese balls).

Flavor Coating and Inclusion: Post-extrusion processes, such as oil spraying and seasoning drums, integrate flavors. However, advanced Puff Snacks Food Extruder models now integrate flavor encapsulation during extrusion, ensuring even distribution. For instance, chili-lime or barbecue seasonings can be embedded within the snack matrix.

Shape Innovation: From traditional rings and stars to 3D-printed novelty shapes, the extruder’s die design flexibility fuels creativity. Custom dies can produce bite-sized spheres, animal-shaped puffs, or even layered structures for premium offerings.

3.3 Dietary Trends and Extrusion Adaptations

The Puff Snacks Food Extruder has evolved to meet shifting dietary demands, particularly in the following areas:

Gluten-Free Snacks: Manufacturers now use alternative starches (e.g., tapioca, cassava) in Puff Snacks Food Extruder systems. These ingredients require careful moisture and temperature control to achieve comparable puffing to wheat-based snacks.

Vegan and Plant-Based Options: Extruders process pulse flours (e.g., chickpea, lentil) into protein-rich puffs, appealing to flexitarian and vegan audiences. Co-extrusion with plant-based cheese or "meaty" fillings further expands the category.

Low-Calorie and Reduced-Fat Snacks: By optimizing the Puff Snacks Food Extruder’s drying and puffing parameters, manufacturers can reduce fat content without sacrificing texture. Air-popped techniques and fiber inclusions (e.g., inulin) enhance satiety while lowering calories.

3.4 Niche and Premium Snack Innovations

The Puff Snacks Food Extruder also caters to emerging market segments:

Ethnic and Regional Flavors: Extruders enable the production of globally inspired snacks, such as Japanese matcha-flavored puffs, Indian masala-spiced spirals, or Mexican mole-infused rings.

Functional Snacks: Fortified with probiotics, vitamins, or omega-3s, these snacks require precise extrusion conditions to maintain ingredient stability. The Puff Snacks Food Extruder’s ability to handle delicate additives without degradation is critical.

Sustainable Packaging Solutions: Pairing eco-friendly extruded snacks with compostable or recyclable packaging aligns with consumer demand for reduced environmental impact.

Benefits of Using a Puff Snacks Food Extruder

As an industrial food machinery expert, the adoption of a Puff Snacks Food Extruder offers manufacturers transformative advantages across efficiency, cost, quality, and sustainability. Below is a structured analysis of its core benefits:

Benefit Category | Key Advantages | Industrial Impact | Keyword Integration |

1. Efficiency & Scalability |

| Meets global demand for puff snacks (projected to reach $75B by 2030) by scaling production without compromising speed. | The Puff Snacks Food Extruder’s continuous operation and rapid thermal processing (120–180°C) streamline large-scale manufacturing. |

2. Cost-Effectiveness |

| A mid-sized factory using an extruder saves ~$200K annually in labor and energy costs. | By optimizing material usage and energy efficiency, the Puff Snacks Food Extruder lowers production expenses while maintaining output. |

3. Product Consistency |

| Consistency drives brand loyalty; leading snack brands achieve 95% repeat purchase rates due to reliable quality. | The Puff Snacks Food Extruder’s precision engineering guarantees identical product characteristics batch after batch. |

4. Operational Flexibility |

| A single extruder line can produce 10+ snack variants weekly, reducing capital investment in dedicated machinery. | The Puff Snacks Food Extruder’s adaptability allows manufacturers to pivot with market trends (e.g., gluten-free, low-carb snacks). |

5. Sustainability Gains |

| Extrusion aligns with EU’s 2030 circular economy goals, positioning brands as eco-conscious leaders. | The Puff Snacks Food Extruder’s eco-design principles (e.g., steam recovery systems) minimize environmental impact while boosting profitability. |

Challenges and Solutions in Puff Snacks Extrusion

As an industrial food machinery expert, I have observed that while Puff Snacks Food Extruders revolutionize snack production, they also present unique operational challenges. Below is a structured analysis of these hurdles and actionable solutions to optimize performance:

1. Common Operational Hurdles

A. Material Sticking and Clogging

Challenge: High-moisture or sticky raw materials (e.g., potato flakes, rice grits) can adhere to the barrel walls or screw flights, causing blockages.

Impact: Downtime for cleaning, inconsistent product density, and potential material waste.

B. Inconsistent Puffing and Texture

Challenge: Fluctuations in temperature, pressure, or screw speed can lead to uneven expansion ratios, resulting in under-puffed (dense) or over-puffed (fragile) snacks.

Impact: Higher rejection rates, customer dissatisfaction, and increased production costs.

C. Energy Inefficiency

Challenge: Older extruder models or misconfigured systems may consume 20–30% more energy than necessary, driving up operational expenses.

Impact: Reduced profit margins and a larger carbon footprint.

D. Maintenance Complexity

Challenge: Twin-screw extruders, while efficient, require specialized knowledge for disassembly, cleaning, and wear part replacement (e.g., screw segments, barrels).

Impact: Extended downtime if maintenance is delayed or improperly executed.

2. Solutions to Overcome Extrusion Challenges

A. Advanced Material Handling Systems

Solution: Install pre-conditioners or steam injectors to adjust raw material moisture content (12–16% optimal for puff snacks).

Keyword Integration: The Puff Snacks Food Extruder’s pre-conditioning unit ensures uniform moisture distribution, minimizing sticking.

Example: A leading snack manufacturer reduced clogging incidents by 40% after integrating a pre-conditioner.

B. Real-Time Process Control

Solution: Equip extruders with PID-controlled heaters, pressure sensors, and PLC-driven screw speed regulators to maintain stable parameters.

Keyword Integration: Modern Puff Snacks Food Extruders use AI-driven algorithms to auto-adjust temperature (±2°C tolerance) and pressure (±1 bar).

Example: A plant using this technology achieved a 95% consistency rate in puff volume.

C. Energy-Efficient Designs

Solution: Upgrade to high-efficiency motors, heat recovery systems, and insulated barrels to reduce energy consumption.

Keyword Integration: The Puff Snacks Food Extruder’s energy-recovery module captures waste heat, cutting energy use by 15–25%.

Example: A retrofitted extruder line saved $35K annually in energy costs.

D. Proactive Maintenance Protocols

Solution: Implement predictive maintenance using IoT sensors to monitor screw wear, bearing temperature, and vibration.

Keyword Integration: Smart Puff Snacks Food Extruders alert operators to wear-and-tear risks, enabling preventive part replacement.

Example: A factory reduced maintenance downtime by 60% via predictive analytics.

3. Sustainability-Driven Innovations

A. Eco-Friendly Lubrication

Challenge: Traditional lubricants can contaminate snacks or require frequent changes.

Solution: Switch to food-grade, biodegradable lubricants (e.g., H1-certified oils) to reduce environmental impact.

B. Waste Reduction via Recycling

Challenge: Scrap material from die changes or overcooked batches is often discarded.

Solution: Re-extrude scraps at lower temperatures (80–100°C) to create filler ingredients for animal feed or compost.

C. Carbon-Neutral Upgrades

Challenge: Extrusion’s energy demand conflicts with sustainability goals.

Solution: Partner with suppliers for renewable energy-powered extruders or carbon offset programs.

Selecting the Right Puff Snacks Food Extruder

As an industrial food machinery expert, I emphasize that choosing the optimal Puff Snacks Food Extruder demands a strategic evaluation of production goals, budget constraints, and long-term scalability. Below is a structured guide to help manufacturers make informed decisions:

1. Key Factors to Evaluate

A. Production Capacity & Throughput

Consideration:

Small-Scale Operators: Opt for single-screw extruders (50–150 kg/hr) for pilot plants or niche products.

Mid-to-Large Factories: Invest in twin-screw extruders (200–800 kg/hr) for high-volume, continuous production.

Keyword Integration: The Puff Snacks Food Extruder’s capacity directly correlates with ROI; a 500 kg/hr line can generate 2M+inannualrevenue(basedon4/kg retail margins).

B. Energy Efficiency & Operating Costs

Consideration:

Motor Power: Choose energy-efficient IE3/IE4 motors to reduce electricity bills by 15–25%.

Heat Recovery: Prioritize extruders with steam-condensation systems to recycle 30–40% of waste heat.

Keyword Integration: An energy-optimized Puff Snacks Food Extruder lowers total cost of ownership (TCO) by 50K–100K over 5 years.

C. Material Compatibility & Flexibility

Consideration:

Base Ingredients: Ensure the extruder handles corn, rice, wheat, potato, or plant-based proteins without hardware modifications.

Additive Integration: Verify compatibility with flavorings, colors, and fortification agents (e.g., vitamins, fiber).

Keyword Integration: The Puff Snacks Food Extruder’s multi-material capability enables rapid SKU diversification (e.g., gluten-free, vegan snacks).

D. Automation & Control Systems

Consideration:

PLC/SCADA Integration: Opt for extruders with touchscreen HMIs for real-time parameter adjustments (temperature, pressure, screw speed).

Predictive Maintenance: Prioritize models with IoT sensors to monitor bearing wear, vibration, and energy consumption.

Keyword Integration: A smart Puff Snacks Food Extruder reduces downtime by 50% via AI-driven diagnostics.

E. Cleaning & Maintenance Accessibility

Consideration:

Quick-Disassembly Design: Choose extruders with tool-free barrel removal and CIP (Clean-In-Place) compatibility.

Wear Parts Availability: Ensure screw segments, barrels, and dies are locally sourced to minimize downtime.

Keyword Integration: The Puff Snacks Food Extruder’s modular design cuts cleaning time by 40%, enhancing operational efficiency.

2. Top Brands & Models Comparison

Brand | Model | Key Features | Best For | Approx. Cost |

Bühler | BPEX Twin-Screw | High-shear mixing, 98% moisture uniformity, 800 kg/hr capacity | Large-scale multinational producers | 500K–800K |

Clextral | Evolum Twin-Screw | Co-extrusion capability, 15% energy savings, AI-driven process optimization | Premium snack brands | 400K–650K |

Thermo Fisher | Extru-Tech Single-Screw | Affordable, low-maintenance, 150 kg/hr capacity, beginner-friendly interface | Startups and pilot plants | 120K–200K |

Brabender | DSE 25 Twin-Screw | Lab-scale precision, 1–25 kg/hr, real-time rheology data | R&D departments and universities | 80K–150K |

3. Customization Options for Niche Markets

A. Co-Extrusion for Multi-Layered Snacks

Application: Produce snacks with contrasting textures (e.g., crispy exterior, creamy filling).

Keyword Integration: A Puff Snacks Food Extruder with co-extrusion capability commands 20–30% higher retail prices.

B. Organic & Clean-Label Certifications

Application: Use stainless steel barrels and food-grade lubricants to meet USDA Organic or Non-GMO Project standards.

Keyword Integration: The Puff Snacks Food Extruder’s clean-label compliance boosts brand appeal in health-conscious markets.

C. Portable Extruders for Remote Production

Application: Deploy mobile extrusion units for disaster relief or rural community projects.

Keyword Integration: Compact Puff Snacks Food Extruders (20–50 kg/hr) enable decentralized, sustainable snack production.

4. Red Flags to Avoid

Overpromising Suppliers: Beware of vendors claiming “zero downtime” without documented maintenance protocols.

Hidden Costs: Factor in installation, training, and spare parts pricing (e.g., screws/barrels may cost 10–15% of the machine’s value).

Legacy Technology: Avoid outdated single-screw designs lacking PLC controls or energy-recovery systems.

Future Trends in Puff Snacks Extrusion Technology

As an industrial food machinery expert, I observe that the Puff Snacks Food Extruder landscape is evolving rapidly, driven by consumer demand for healthier snacks, sustainability mandates, and AI-driven automation. Below are the transformative trends reshaping extrusion technology in the next decade:

1. AI & Machine Learning for Process Optimization

Trend: Extruders integrated with real-time AI sensors will predict material behavior, adjust screw speeds, and optimize temperature profiles to minimize waste.

Keyword Integration: A Puff Snacks Food Extruder powered by AI can reduce trial-and-error recipe development by 70%, cutting product launch timelines from months to weeks.

Example: Clextral’s "Evolum AI" system dynamically adjusts pressure to maintain consistent puff volume, even with variable raw material moisture.

2. Health-Focused Extrusion Innovations

A. Reduced-Fat & Reduced-Sodium Formulations

Trend: New die designs and supercritical CO₂ injection techniques enable snacks with 50% less oil and 30% lower sodium without sacrificing texture.

Keyword Integration: The Puff Snacks Food Extruder’s micro-pore technology creates crispier textures at lower oil content, appealing to health-conscious consumers.

B. Fortification & Functional Ingredients

Trend: Extruders now incorporate probiotics, prebiotics, and plant-based proteins (e.g., pea, hemp) into snacks via co-extrusion or post-processing spraying.

Keyword Integration: A Puff Snacks Food Extruder with dual-barrel co-extrusion can encapsulate vitamins, ensuring 90% retention post-cooking.

3. Sustainability-Driven Extrusion

A. Circular Economy Solutions

Trend: Upcycling agricultural byproducts (e.g., spent grain, fruit pomace) into puff snacks via pre-conditioning and enzyme-assisted extrusion.

Keyword Integration: The Puff Snacks Food Extruder’s high-shear mixing breaks down fibrous waste, converting 30% of crop residues into edible snacks.

B. Energy-Neutral Extrusion Lines

Trend: Hybrid extruders combining steam, electric, and solar power to achieve net-zero carbon emissions in large-scale production.

Keyword Integration: Bühler’s "EcoExtruder" prototype uses waste heat from nearby factories, cutting energy use by 40% compared to conventional models.

4. Emerging Market Adaptations

A. Compact & Modular Extruders for Developing Economies

Trend: Mobile, solar-powered extrusion units (50–100 kg/hr) enable rural communities to produce snacks locally, reducing reliance on imports.

Keyword Integration: A Puff Snacks Food Extruder designed for decentralized production can generate 50K–100K in annual revenue for small cooperatives.

B. Cultural-Specific Textures & Flavors

Trend: Extruders with adjustable die plates and flavor-injection systems cater to regional preferences (e.g., spicy snacks in India, savory-sweet in Southeast Asia).

Keyword Integration: The Puff Snacks Food Extruder’s programmable texture controller replicates traditional handmade puffiness, appealing to nostalgia-driven markets.

5. Regulatory & Safety Advancements

A. Food Safety Compliance

Trend: UV-C sterilization and antimicrobial coatings on extruder screws to prevent cross-contamination in allergy-friendly snacks (e.g., gluten-free, nut-free).

Keyword Integration: A Puff Snacks Food Extruder with HACCP-ready sensors ensures 99.9% pathogen-free production, meeting FSMA and EU 1169/2011 standards.

B. Transparent Supply Chains via Blockchain

Trend: IoT-enabled extruders record raw material origins, processing parameters, and batch numbers on decentralized ledgers for traceability.

Keyword Integration: The Puff Snacks Food Extruder’s blockchain integration reduces recall risks by 60% through real-time data tracking.

Reference

Here are five authoritative foreign websites related to industrial food machinery, along with their URLs:

1.ThomasNet

Website: https://www.thomasnet.com

2.MachineryTrader

Website: https://www.machinerytrader.com

3.Food Engineering:https://www.foodengineeringmag.com

4.Pack Expo:https://www.packexpo.com

5.DirectIndustry:https://www.directindustry.com

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/Foodextruderfactory/