Discovering The World Of Corn Snack Extruder

Introduction to Corn Snack Extruder

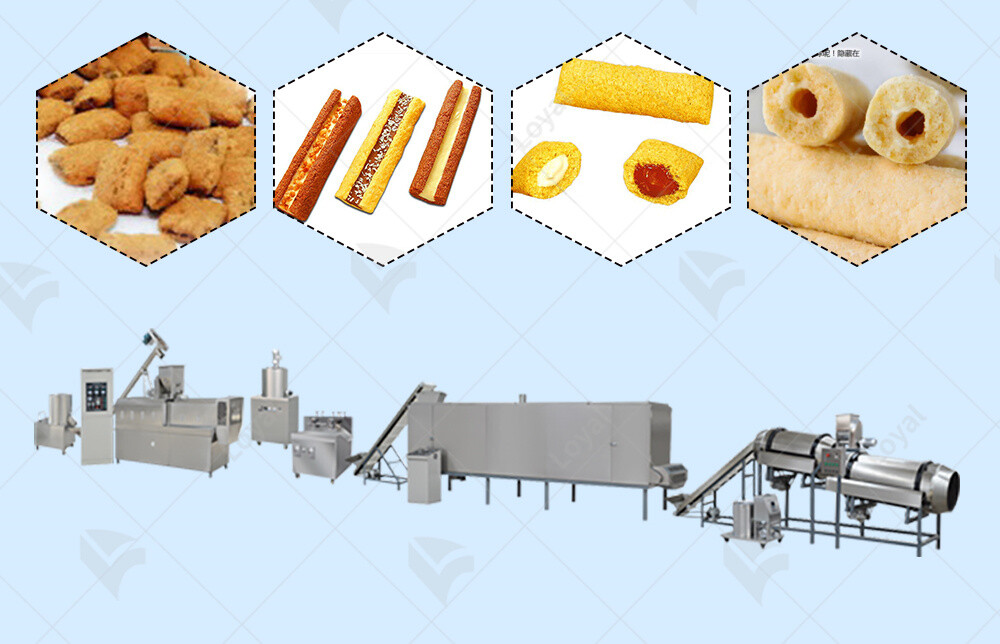

In the vast landscape of food processing machinery, the corn snack extruder stands as a pivotal innovation that has revolutionized the snack industry. As an industrial food mechanism, the corn snack extruder is specifically designed to transform raw corn ingredients into a variety of delicious and crunchy snacks. This machine utilizes advanced extrusion technology to shape, cook, and texture the corn dough, creating a wide array of products that cater to diverse consumer preferences.

The c operates on the principle of extrusion, a process where a material is forced through a die under pressure to achieve a desired shape or texture. In the context of corn snacks, this machine takes raw corn flour, water, and other ingredients, mixes them together, and then extrudes the mixture through a series of dies to form various shapes and sizes. The extrusion process not only shapes the snacks but also cooks them, creating a ready-to-eat product that is both crispy and flavorful.

As an expert in industrial food machinery, I can attest to the importance of the corn snack extruder in the modern food industry. Its ability to efficiently produce a wide range of snacks with consistent quality and taste makes it an indispensable tool for manufacturers looking to capitalize on the growing demand for convenient and delicious snack options.

Types and Functions of Corn Snack Extruder

In the fascinating world of food machinery, the corn snack extruder stands out as a versatile and efficient tool for creating a myriad of delicious and crunchy snacks. As an industrial food machinery expert, I am here to delve into the various types and functions of corn snack extruders, shedding light on their unique capabilities and applications.

The corn snack extruder comes in several forms, each tailored to meet specific production needs and desired snack characteristics. One of the most common types is the single-screw corn snack extruder. This machine features a single rotating screw within a barrel, which pushes the corn dough through a die to form the desired shape. The single-screw extruder is known for its simplicity, cost-effectiveness, and suitability for producing a wide range of snack shapes and sizes. It is often the go-to choice for small to medium-sized snack manufacturers looking to enter the market with a variety of corn-based snacks.

For those seeking higher production capacity and more intricate snack designs, the twin-screw corn snack extruder offers a superior alternative. This machine features two parallel rotating screws that work in tandem to mix, knead, and extrude the dough. The twin-screw design allows for better control over the dough's temperature and consistency, resulting in snacks with a more uniform texture and appearance. Additionally, the twin-screw extruder can accommodate a wider range of ingredients and formulas, making it ideal for innovative snack developers who want to push the boundaries of taste and texture.

Another type of corn snack extruder gaining popularity is the high-speed extruder. As the name suggests, this machine operates at much faster speeds than traditional extruders, enabling manufacturers to produce large volumes of snacks in a shorter period. High-speed extruders are equipped with advanced control systems that monitor and adjust the extrusion process in real-time, ensuring consistent product quality and minimizing waste. These machines are perfect for large-scale snack production facilities that need to meet high demand while maintaining stringent quality standards.

Each type of corn snack extruder serves a distinct purpose and offers unique benefits to snack manufacturers. The single-screw extruder provides a cost-effective entry point into the snack market, while the twin-screw extruder offers greater versatility and control over product quality. The high-speed extruder, on the other hand, is tailored for high-volume production with minimal downtime.

In conclusion, the corn snack extruder is a cornerstone of the modern snack manufacturing industry. With its ability to produce a wide variety of delicious and crunchy snacks, this versatile machine continues to evolve and adapt to meet the ever-changing needs of consumers and manufacturers alike. Whether you're a small startup or a large-scale producer, choosing the right type of corn snack extruder is crucial for achieving success in the competitive snack market.

The Process of Corn Snack Extrusion

In the fascinating world of food processing machinery, the corn snack extruder stands out as a pivotal piece of equipment that transforms simple corn flour into a variety of delightful and crunchy snacks. As an industrial food machinery expert, I am delighted to delve deeper into the process of corn snack extrusion, which is not only intricate but also highly efficient.

The journey begins with the meticulous preparation of the corn flour and other essential ingredients. High-quality corn flour forms the backbone of these snacks, providing the necessary structure and flavor. To enhance the taste and nutritional profile, other ingredients such as seasonings, vitamins, and minerals may be added. The precise measurement and blending of these components are crucial steps, ensuring a consistent and homogeneous mixture that is ready for the extrusion process.

Once the ingredients are meticulously prepared, they enter the mixing and kneading stage. In this critical phase, the mixture is subjected to intense mechanical action, which helps to develop the dough's gluten structure. This is essential for achieving the desired texture and mouthfeel of the final snack. The mixing and kneading process also ensures that all ingredients are evenly distributed throughout the dough, contributing to a uniform product appearance and taste.

The extrusion and shaping stage is where the magic happens. The prepared dough is fed into the corn snack extruder, where it is subjected to high pressure and temperature. As the dough passes through the extruder's die, it is forced out in the desired shape and size. The extruder's precision engineering allows for the creation of intricate designs and textures, catering to a wide range of consumer preferences. The high pressure and temperature during extrusion also contribute to the formation of a crispy outer layer and a soft, chewy interior, characteristics that are highly sought after in corn snacks.

Immediately after extrusion, the shaped snacks enter the cooling phase. This step is crucial for solidifying the snack's structure and preventing deformation. The snacks are conveyed through a cooling tunnel, where they are exposed to controlled temperatures and airflows. This ensures that they cool down evenly and maintain their shape and texture.

Finally, the cooled snacks are ready for packaging. Packaging not only protects the snacks from environmental contaminants but also extends their shelf life. Various packaging options are available, ranging from simple polythene bags to more sophisticated retort pouches that allow for the sterilization and preservation of the snacks. The choice of packaging depends on the intended market and consumer preferences.

In conclusion, the process of corn snack extrusion is a well-orchestrated sequence of steps that transforms simple corn flour into delicious and crunchy snacks. Each stage, from ingredient preparation to packaging, plays a vital role in ensuring the quality and consistency of the final product. As food machinery technology continues to evolve, the corn snack extruder remains a cornerstone of the food processing industry, delivering innovation and efficiency in snack production.

Benefits and Advantages of Using Corn Snack Extruder

Benefit/Advantage | Description |

Increased Production Efficiency | The automated nature of corn snack extruders significantly boosts production rates compared to traditional methods. With minimal human intervention required, these machines can run continuously, producing large volumes of snacks in a short timeframe. This not only reduces labor costs but also ensures a steady supply of products to meet market demand. |

Consistency in Product Quality | Corn snack extruders are designed to maintain consistent pressure, temperature, and mixing conditions throughout the extrusion process. This results in snacks that have a uniform texture, color, and taste, enhancing consumer satisfaction and brand reputation. |

Variety of Shapes and Sizes | The versatility of corn snack extruders allows manufacturers to produce a wide range of shapes and sizes. By changing the die plate at the end of the extruder, different shapes such as balls, sticks, or twists can be easily achieved. This variety appeals to a broader consumer base and supports product differentiation in a competitive market. |

Cost-effective Manufacturing | The use of corn snack extruders minimizes waste and maximizes raw material utilization. With precise control over the extrusion process, manufacturers can reduce the amount of scrap and overproduction, leading to lower costs per unit. Additionally, the durability and longevity of these machines mean that they offer a high return on investment over time. |

Flexibility in Ingredient Incorporation | Corn snack extruders can accommodate a variety of ingredients, including flours, sugars, fats, and seasonings. This flexibility allows manufacturers to experiment with different recipes and create unique flavors and textures that appeal to consumers. Furthermore, the extrusion process can help to evenly distribute ingredients throughout the snack, ensuring consistent taste and appearance. |

Scalability and Customization | Corn snack extruders come in various sizes and capacities, making them suitable for both small-scale and large-scale production. Manufacturers can choose a machine that best fits their production needs and can easily scale up or down as required. Additionally, some extruders offer customizable features such as adjustable temperature settings and variable speed controls, providing even greater flexibility in the production process. |

Challenges and Considerations in Corn Snack Extrusion

Maintenance and Cleaning of Extruder Equipment

Challenge Overview

Maintaining and cleaning corn snack extruder equipment is crucial for ensuring continuous and high-quality production. The accumulation of residue, moisture, and other contaminants can lead to equipment malfunction, reduced product quality, and even food safety issues.

Considerations for Maintenance

Regular Inspections: Schedule routine inspections of the extruder machinery to identify and address potential issues before they escalate.

Preventive Maintenance: Implement a preventive maintenance program to extend the lifespan of the equipment and reduce downtime.

Training and Expertise: Ensure that operators are trained on proper maintenance procedures and have access to expert guidance when needed.

Cleaning Protocols

Sanitization Standards: Follow strict sanitation standards to eliminate harmful microorganisms and prevent cross-contamination.

Disassembly and Reassembly: Regularly disassemble and reassemble the extruder components for thorough cleaning and inspection.

Use of Approved Cleaning Agents: Utilize cleaning agents that are approved for food contact surfaces to avoid contamination and ensure compliance with food safety regulations.

Impact on Production

Effective maintenance and cleaning practices can significantly reduce production disruptions, improve product quality, and enhance overall equipment performance. By addressing these challenges, manufacturers can optimize their corn snack extrusion process and maximize their return on investment.

Innovations and Trends in Corn Snack Extrusion Industry

Technological Innovations

Advanced Extrusion Technology:

High-Precision Extruders: Manufacturers are now equipping their corn snack extruders with high-precision components to ensure consistent product quality and reduce waste.

Automation and Control Systems: The integration of automation and advanced control systems allows for real-time monitoring and adjustment of extrusion parameters, enhancing production efficiency and product consistency.

Material Handling and Processing:

Improved Mixing and Kneading Techniques: New mixing and kneading technologies ensure uniform distribution of ingredients and improve the structure of the dough, leading to better extrusion results.

Efficient Cooling and Packaging Solutions: Advanced cooling systems and packaging techniques maintain the freshness and quality of the snacks, extending their shelf life.

Emerging Ingredients and Flavors

Organic and Non-GMO Ingredients: Consumers are increasingly seeking snacks made from organic and non-GMO ingredients. Manufacturers are responding by incorporating these ingredients into their corn snack extrusion processes.

Unique Flavors and Textures: To cater to diverse palates, corn snack extruder manufacturers are experimenting with unique flavors and textures, such as spicy, sweet, and crunchy varieties.

Consumer Preferences and Market Trends

Health and Wellness:

Reduced Sodium and Sugar Content: Health-conscious consumers prefer snacks with reduced sodium and sugar content. Manufacturers are adjusting their extrusion recipes to meet these demands.

Whole Grain and Fiber-Rich Options: Snacks made from whole grains and high-fiber ingredients are gaining popularity due to their nutritional benefits.

Sustainability and Eco-Friendliness:

Eco-Friendly Packaging: Manufacturers are adopting eco-friendly packaging materials to reduce their carbon footprint and appeal to environmentally conscious consumers.

Energy Efficiency: Corn snack extruders are being designed to consume less energy and produce fewer emissions, contributing to sustainable production practices.

Reference

Here are five authoritative foreign websites related to industrial food machinery, along with their URLs:

1.ThomasNet

Website: https://www.thomasnet.com

2.MachineryTrader

Website: https://www.machinerytrader.com

3.Food Engineering:https://www.foodengineeringmag.com

4.Pack Expo:https://www.packexpo.com

5.DirectIndustry:https://www.directindustry.com