Comprehensive analysis of technology of corn flakes production line

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/Foodextruderfactory/

Introduction of corn flakes

Corn flakes are a kind of ready-to-eat food made of corn as the main raw material through extrusion, molding, baking and other processes. It was first invented by American doctor John Harvey Kellogg in the late 19th century and was initially promoted as a health food. Modern corn flakes not only retain the original nutritional value, but also develop a variety of flavors and forms, becoming a popular breakfast and snack choice around the world.

Main uses of corn flakes:

1. Breakfast food: can be eaten directly with milk, yogurt or fruit, and about 60% of households in Europe and the United States use it as a daily breakfast.

2. Snacks: can be eaten alone or as an ingredient for mixed nuts and dried fruits, and the leisure food market accounts for about 25%.

3. Deeply processed raw materials: used to make energy bars, cereal bars and other foods, accounting for about 15% of the raw materials in the food industry.

4. Export market: Europe, the United States, Southeast Asia and other regions have a strong demand for corn flakes. The global market size will reach US$10.5 billion in 2022, with an annual growth rate of about 4.3%.

Introduction of corn flakes production line

Modern corn flakes production line adopts modular and automated design. The whole line length is usually 30-50 meters and covers an area of about 200-300 square meters. The production line design complies with HACCP and GMP standards, and the whole process from raw material processing to finished product packaging is controllable, ensuring stable product quality and high production efficiency.

Technical parameters of the breakfast cereals production line

| Model | Installed Power | Power Consumption | Output | Size (L*W*H) |

| LY65 | 140kw | 90kw | 120-150kg/h | 39000*1200*2200mm |

| LY70 | 160kw | 120kw | 180-220kg/h | 41000*1500*2200mm |

| LY75 | 190kw | 140kw | 300-500kg/h | 43000* 3500*4300mm |

| LY95 | 240kw | 190kw | 800-1000kg/h | 65000*5000*4300mm |

Equipment list ofcorn flakesmaking machine

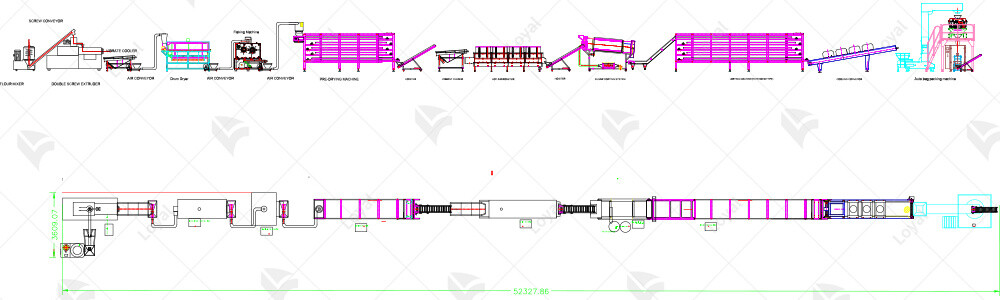

Mixer ---Screw Conveyor---Double Screw Extruder ---Vibrate Cooler--- Air Conveyor---Flaking Machine---AirConveyor---Pre-dryer---Hoister --Vibrate Feeder---High Temperature Baking Machine---Sugar Sprayer---Multi-layer Oven---Cooling Conveyor---Packing Machine

In the corn flakes manufacturing line,the functions of each equipment are as follows

Machine name | fountion |

Mixer | Mix corn flour and other raw materials in a certain proportion, and add appropriate amount of water, additives, etc. according to the production process requirements to make the raw materials reach the appropriate humidity and properties, ready for subsequent processing.

|

Screw conveyor | Use the rotation of the spiral blade to push corn flour and other materials to move in a closed pipe or tank, and transport the mixed powder from one position to another, such as transporting the materials in the mixer to the feed port of the twin-screw extruder. |

Twin-screw extruder | Through the rotation of two intermeshing screws in the barrel, the materials are extruded, sheared, kneaded and heated, so that the materials undergo physical and chemical changes under high temperature and high pressure to form semi-finished products with certain shapes and properties. |

Vibration cooler | Cool the high-temperature materials coming out of the twin-screw extruder, disperse the materials evenly through vibration, accelerate the cooling process, prevent the materials from deformation or deterioration due to high temperature, and facilitate subsequent processing. |

Flaking machine | Press the cooled material into sheets. By adjusting the pressure of the tablet press and the gap between the rollers, the thickness and density of the corn flakes are controlled to meet the specifications required by the product. |

Air conveyor | Use wind power to transport the pressed corn flakes to a designated location, such as transporting corn flakes from the tablet press to a multi-layer oven or other subsequent equipment. During the transportation process, the corn flakes can also be preliminarily screened and separated. |

Multi-layer oven | Bake the corn flakes. By controlling the temperature, wind speed and baking time in the oven, the corn flakes are further cooked during the heating process, excess moisture is removed, and crispness and aroma are increased |

Elevator | Elevate the corn flakes from a lower position to a higher position, such as lifting the corn flakes baked in a multi-layer oven to the feed port of a high-temperature baking machine or other subsequent processing equipment, so as to realize vertical transportation of materials in the production line. |

Vibrating feeder | feed corn flakes evenly and stably into the equipment of the next process, and make the material flow continuously in the hopper through vibration to avoid material accumulation and blockage, and ensure the continuity of production. |

High temperature baking machine | bake corn flakes at high temperature to further improve the crispness and color of corn flakes, so that corn flakes have a unique flavor and taste, and meet the quality requirements of the product. |

Sugar sprayer | spray syrup or other seasonings evenly on the surface of corn flakes to increase the sweetness and flavor of corn flakes, improve the taste and appearance of the product, and make corn flakes more attractive |

Cooling conveyor | cool the corn flakes after sugar spraying and other treatments, so that the syrup or seasonings on the surface of the corn flakes can be quickly solidified, and the temperature of the corn flakes can be reduced to facilitate subsequent packaging, and prevent the corn flakes from sticking or deteriorating due to excessive temperature during packaging. |

Packaging machine | Measure and package the cooled corn flakes. According to the product specifications, a certain amount of corn flakes are put into packaging bags or boxes to achieve the final packaging of the product for easy storage, transportation and sales. |

Advantages of corn flakes production line

1. High-precision automated control system

Equipped with an advanced PLC system, the entire production process can be accurately controlled, including the ratio of raw materials, baking temperature, pressure, etc. This not only improves the accuracy of production, but also reduces human operating errors and ensures the consistency and stability of the product.

2. Versatility and flexibility

Usually able to handle a variety of different raw materials and formulas, such as corn, rice, whole wheat, etc., different grain raw materials can be selected according to market demand. At the same time, the production line can produce a variety of corn flakes with different shapes, tastes, and thicknesses by adjusting the formula, process parameters or molds to meet the needs of different consumers.

3.Refined surface treatment and coating technology

The corn flake production line can perform fine coating treatment on the surface of corn flakes, such as adding natural syrup, salt, seasonings, etc., to achieve more precise flavor control and more uniform coating distribution. Such technology can not only improve the taste of corn flakes, but also ensure the consistent appearance of each piece of product.

4.Precise baking and puffing technology

High-end production lines are equipped with more precise puffing and baking technology, which can effectively control the expansion rate and baking degree of corn flakes to ensure the crispness and color of the product. This can avoid over-baking or under-puffing, and ensure the high-quality appearance and taste of the product.

5.Personalized customization and innovation capabilities

Usually have stronger R&D and customization capabilities, and can produce customized products such as unique flavors, shapes, and nutritional ingredients according to customer needs. For example, adding healthy formulas such as high fiber, low sugar or gluten-free to meet the needs of modern consumers for healthy food.

6.Fully automatic packaging system

Equipped with an automated packaging system, it can not only increase the packaging speed, but also ensure the accuracy and aesthetics of the packaging. High-end packaging may also include more high-end materials and designs to enhance the market image of the product.

7.Sanitary and safe design in line with international standards

The design pays more attention to hygiene and safety, and the production equipment and production environment meet international food safety standards, such as CE, ISO certification, etc., to ensure that the products are pollution-free and meet strict quality control requirements.

Through these advanced technologies and designs, high-endcorn flakes production linescan not only meet high-quality production needs, but also maintain competitiveness in product innovation, market positioning and production efficiency. This makes them more suitable for providing consumers with high-end, healthy and innovative corn flakes products to meet the ever-changing market needs.

FAQ

1.We are very concerned about the quality and stability of the equipment. Can the quality of domestic production lines be comparable to that of foreign equipment?

In recent years, domestic corn flake production lines have made great progress in technology and craftsmanship, and many domestic manufacturers have been able to provide equipment comparable to international brands. We use advanced production technology and strict quality control system. All equipment will undergo rigorous testing and quality inspection before leaving the factory to ensure the stability and efficiency of the equipment. At the same time, domestic corn flake production lines usually also meet international standards, such as ISO, CE and other certifications.

2.We have specific production requirements, such as corn flakes of different shapes and flavors. Can your company's production line meet them?

Our corn flake production line is highly flexible and adjustable, and can be customized in different shapes, sizes and formulas according to customer needs. We have rich customization experience and can help you adjust the configuration of the production line to meet the needs of specific flavors and nutrients (such as low sugar, gluten-free, etc.). You can choose different functional modules according to market demand to ensure that corn flakes that meet your brand needs are produced.

3.How is the automation control system of the production line? Does it require a lot of manual operation?

Our puffed corn linehas a high level of automation, equipped with a PLC control system and HMI touch screen. All parameters in the production process (such as temperature, humidity, time, etc.) can be accurately controlled, and most of the production process is automated. Only a small number of staff are needed to monitor and maintain the equipment, which greatly reduces labor costs, while also improving production efficiency and consistency of product quality.

4. After we purchase the equipment, what kind of after-sales support can we get in case of failure or problems?

We provide comprehensive after-sales service, including equipment installation and commissioning, operator training, regular maintenance, etc. Our technical team can provide remote support, and if necessary, we can send technicians to the site for repairs and maintenance. In addition, we also provide long-term spare parts guarantee to ensure that your production line can operate stably for a long time.

5.How is the energy efficiency of the production line? Is it environmentally friendly and can it reduce energy consumption?

Our corn flakes production lineuses advanced energy-saving technologies, such as heat recovery systems and high-efficiency heating equipment, which can effectively reduce energy consumption. Compared with traditional production lines, our equipment can save more energy and reduce production costs. In addition, the design of the production line also meets environmental protection requirements to ensure that the discharge of waste gas and wastewater meets international environmental standards.

About Us

We are a professional manufacturer of food machinery and we have been manufacturing nutrition cereal bar processing line for nearly 20 years. In addition to the Nutrition Cereal Bar snack processing line, we also manufacture lines for deep-fried food, pet feed, modified starch and many more. Each of our lines has basically a variety of moulds, which can be adapted to produce a wide range of food products. We are not satisfied with the status quo but are constantly upgrading and innovating our products, adapting our production plans and designs to the changing needs of the times and keeping up with the pace of progress. Never satisfied with the pursuit of excellence!

Production Market

Our products are exported to all over the world, especially Europe, the United States, Asia and the Middle East. Through exchanges and cooperation with well-known foreign high-tech companies such as Japan, Germany, Italy, etc., we now have more and more customers from North and South America.