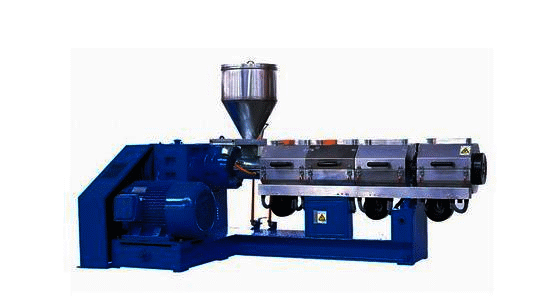

What parts of a single screw extruder machine consist of?

The structure of the single-screw extruder is relatively simple. It is composed of a screw rotating in a heated barrel.

It is easy to manufacture, high in processing efficiency, and low in price, so it is widely used.

At the same time, because the single-screw extruder occupies a small space, it has become the main equipment used in the field of compound processing and plastic blown film.

Single Screw Extruder Machine has developed from the initial basic spiral structure to various structure types such as damping screw block, exhaust screw, slotted screw barrel, pin barrel, building block structure, etc.

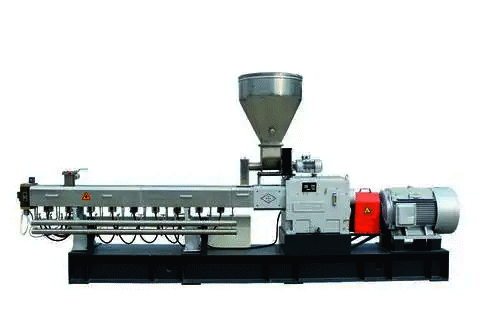

The single screw extruder machine mainly It is composed of three parts:

extrusion system, transmission system and heating and cooling system. These three parts are described in detail below.

1.Extrusion system

The extrusion system mainly includes the feeding device, screw and barrel. It is the most critical part of the extruder. The screw is the heart of the extruder.

The material can move in the barrel through the rotation of the screw and increase Pressure and some heat.

The main function of the extrusion system is to melt the polymer material into a plasticized uniform melt, realize the transition from the glass state to the viscous flow state.

And form a certain pressure in the process, which is continuously extruded and transported by the screw From the machine to the die.

The extrusion system plays a very important role in the molding quality and output of extrusion processing.

2. Transmission system

The transmission system is usually composed of a motor, a reducer and a bearing.

Its main function is to drive the screw and supply the torque and torque required by the screw during the extrusion process.

During the extrusion process, it is required that the screw speed is stable and does not change with the change of screw load to ensure uniform product quality.

However, under different occasions, the screw is required to be able to achieve variable speed.

So that a piece of equipment can meet the requirements of extruding different materials or products of different shapes.

In most extruders, the change of screw speed is achieved by adjusting the speed of the motor. The system is also equipped with a good lubrication system and rapid braking device.

3. Heating and cooling system

The heating and cooling system of the extruder consists of a heating device and a cooling device, which can ensure the smooth progress of the extrusion process.

The heating device and the cooling device must ensure that the polymer material is melted and plasticized .The temperature during the molding process meets the process requirements.

The cooling device is generally set in the extruder's barrel, screw, and the bottom of the hopper. The barrel can be water-cooled or air-cooled.

Generally, small and medium-sized extruders use air-cooled methods, and large-scale extruders use water-cooled methods. Or a combination of the two methods.

The screw cooling mainly adopts central water cooling. The purpose of this is to increase the conveying rate of the solid material, stabilize the output, and improve the quality of the product at the same time.

The cooling device at the bottom of the hopper is mainly to strengthen the conveying effect of solid materials.

And prevent the material particles from sticking due to the increase in temperature, blocking the material opening and affecting the feeding.

Generally, for extruders and high-speed extruders with a screw diameter of more than 90 mm, a cooling device must be installed at the bottom of the hopper.

The above is the introduction to the composition of the single-screw extruder, which is mainly composed of the extrusion system, transmission system, heating and cooling system.

The respective structures of these three parts have also been explained in detail. I believe you have already read this.

With a deeper understanding, the application range of single screw extruder machine is still very broad, which brings great convenience to the society.