What is the fish feed made of?

Consumers now have a very high demand for aquatic products, because fish has very high nutritional value and low fat content, which is very friendly to our health, so many people choose to use fish instead of pork or beef.

The expansion of fish farming has caused the demand for fish feed to continue to rise. High-quality fish feed can greatly shorten the growth period of fish and bring huge profits to farmers. High-quality fish feed requires the use of high-quality formulas. What exactly is the feed made of?

What is the fish feed made of?

Fish feed mainly refers to the feed for fish. There are many types. The main ingredients are protein, fat, vitamins and minerals. Only when the nutrition is comprehensive can the normal growth of fish be ensured. Among them, protein is very important. It is the most important nutrient to ensure the growth of fish, which can enhance the immunity of fish and reduce the occurrence of diseases.

Different fish foods use different formulas, so there will be some differences in raw materials, but generally speaking, the main raw materials for fish food are corn meal, soybean meal, meat, bone meal, wheat flour, low-temperature soybean meal, rice bran, wheat Bran and fish meal, etc., different stages of fish need different nutrients, so different formulas are needed to make different fish foods.

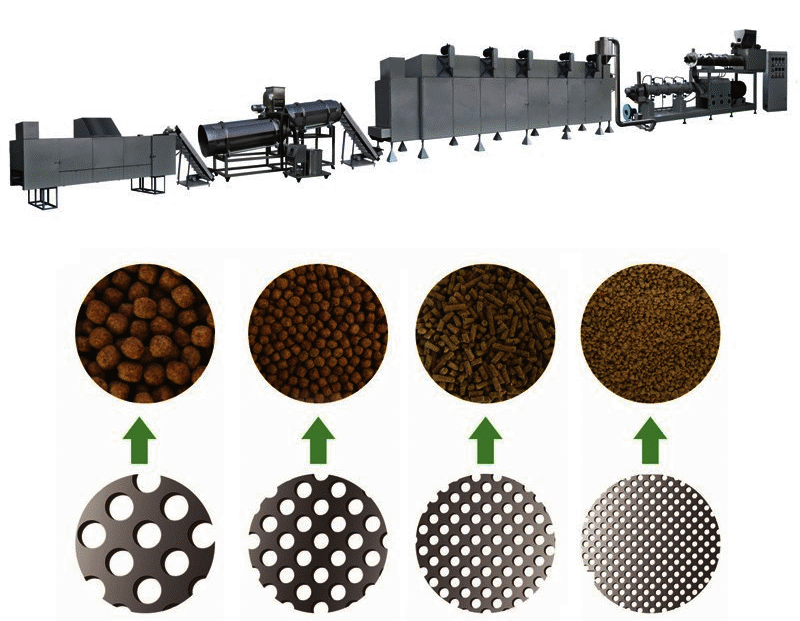

The production of fish food requires a relatively high level of technology. Only in this way can the nutrition of the fish food be ensured. At present, most feed processing plants use extrusion technology to produce fish food. The Fish Feed Production Line uses the most advanced technology in the world. With extrusion technology, the fish food produced is rich in nutrients and has good palatability.

How to make fish food:

1. First, mix the raw materials according to the fish feed formula, add an appropriate amount of water and mix well in a mixer.

2. The raw materials are transported to the twin-screw extruder, where they are extruded and expanded under high temperature and high pressure.

3. Transport the fish food to the dryer for drying treatment to extend the shelf life.

4. Season the fish food in the seasoning line to make it more palatable.

5. Use a cooler to cool the fish food to prevent the moisture from returning after packaging and affect the quality of the fish food.

6. Use a packaging machine for packaging.

Use high-quality formulas, high-quality raw materials, and then use superior equipment for production, so that high-quality fish food can be produced, which can be recognized by more farmers and further expand the market scale.

The performance of the Fish Feed Production Line has reached the international leading level, and with its excellent quality, it has been exported to many countries and regions around the world. It has established a complete market network around the world. Many well-known companies have further expanded the market by using this production line.

The fish food production line is highly automated and is made of food-grade materials and internationally renowned brand components. The equipment is of reliable quality, high production efficiency, simple operation, convenient maintenance, small footprint, and the most important thing is that it is cheaper than large-scale equipment. The investment is much lower, but it can provide manufacturers with very strong productivity, with a very high cost performance, and quickly pay back within a few months. Therefore, the production line has been recognized by many manufacturers.

If you want to improve your production technology level to gain a broader market, welcome to contact us, we can provide you with customized services, and you can definitely get the most satisfying equipment!