Automatic Fish Feed Production Line with High Cost - Effectiveness

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/Foodextruderfactory/

The importance of fisheries in the global agricultural economy

Fisheries are becoming increasingly important in the global food system. According to FAO data, the annual output of aquatic products in the world continues to rise, providing a large amount of protein for humans and ensuring the livelihoods and nutrition of hundreds of millions of people. It not only meets dietary needs, but also has far-reaching significance for agricultural economic growth and international trade balance.

The key role of fish feed in fish farming

In modern fish farming, fish feed is a key factor. Scientific fish feed can meet the nutritional needs of fish at different growth stages, help them grow healthily, and at the same time reduce water pollution and improve farming efficiency. With the expansion of fish farming and intensive development, traditional feed production methods are difficult to meet market demand. Automaticfish feed making machinehave the advantages of high efficiency, precision and stability, and are favored by farmers and feed companies for their high cost performance, becoming an important driving force for the modernization of fisheries.

Introduction of fish feed

Fish feed is a substance that is artificially fed to meet the nutritional needs of fish growth and development. The core nutrients include protein, fat, vitamins and minerals. Protein is the key to the composition of fish bodies, and its deficiency will affect growth and immunity; fat, vitamins and minerals are essential for fish immunity and disease resistance.

In fish farming, scientific and reasonable fish feed is of great significance, and feed costs account for more than 80% in intensive farming. From the fry to the adult stage, it is necessary to reasonably select feed according to the feeding habits and growth stages of different fish species, and adjust feeding according to the environment and fish body conditions. During the high incidence period of fish diseases, medicated bait can also be used to prevent diseases.

Fish feed production line introduction

With the continuous expansion of the scale of aquaculture, the market demand for the quality and output of fish feed is growing. In line with this industry trend, the company has developed a variety of fish feed processlines, providing diversified configuration solutions based on different breeding scales and output requirements. The production line uses fish meal, soybean meal, corn meal, wheat bran, etc. as the main raw materials. By precisely controlling the process parameters such as raw material ratio, granulation temperature, and material moisture, it can produce fish feed with uniform particles, good palatability, balanced nutrition, and high digestibility, which can meet the feeding needs of fish of different growth stages and different species. Whether it is starter feed for juveniles or fattening feed for adult fish, it can be efficiently produced, providing strong support for improving the quality and efficiency of aquaculture.

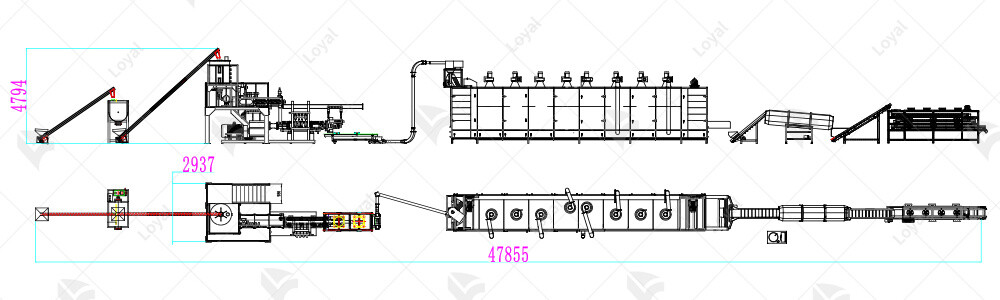

Equipment list of Big Capacity Dry Fish feed production line

Flour MixeràScrew ConveyoràDouble Screw Extruder à Air ConveyeràOvenààFlavoring machine à Cooling Machine

Working Process of thefish feed processline

1.Flour Mixer: The mixing machine is used to mix and stir various raw materials like flour, sugar, cooking oil, water, and different additives according to a specific formula ratio. Through thorough stirring, all the raw materials are uniformly blended to form a dough with a certain viscosity and plasticity, laying a solid foundation for the subsequent production of biscuits.

2.Screw Conveyor: The screw conveyor is mainly employed to transport the mixed dough or other raw materials from one location to another. When the spiral blades inside rotate, they push the materials to move within the conveying pipeline. This conveyor features stable transportation and excellent sealing performance, which can effectively prevent material leakage and contamination.

3.Twin - Screw Extruder: The twin - screw extruder further processes the dough through the rotation and extrusion of the two screws, making it take shape and undergo preliminary cooking. According to different molds and process requirements, it can extrude the dough into biscuit blanks of various shapes and specifications. Moreover, during the extrusion process, the dough will be heated and reach a certain degree of cooking.

4.Air Conveyor: The air conveyor utilizes wind power to transport the biscuit blanks from the extruder to the oven or other subsequent equipment. The airflow generated by the fan makes the biscuit blanks float and be transported within the pipeline. This method has the advantages of fast conveying speed and being less likely to damage the blanks.

5.Oven:The oven is one of the key pieces of equipment in biscuit production and is mainly used for baking biscuit blanks. The heating elements generate heat and bake the biscuit blanks under specific temperature and time conditions. During the baking process, the moisture in the biscuit blanks evaporates, the starch gelatinizes, and the protein denatures. As a result, the baked biscuits have a crispy texture, a unique flavor, and an attractive appearance in terms of color.

6.Flavoring Machine:The flavoring machine can evenly spray or apply various seasonings, such as salt, sugar, chocolate sauce, cream, etc., onto the surface of the biscuits. This can enhance the flavor of the biscuits and meet the taste preferences of different consumers.

7.Cooling Machine: The function of the cooling machine is to cool the baked biscuits. Through forced ventilation or other cooling methods, it quickly reduces the temperature of the biscuits, dissipates the heat, and stabilizes the internal structure of the biscuits. This prevents the biscuits from becoming soft, deforming, or deteriorating due to excessive temperature during the subsequent packaging process, and it also helps improve the efficiency and quality of packaging.

The Detail Descriptions of Thefish feed production line

| No. | Item | Detail descriptions of fish feed making machine |

| 1 | Raw materials | Meat meal, fish meal, bone powder, corn powder, soya meal and other grains’ powder, etc. |

| 2 | Consumption | Low power and labor consumption |

| 3 | Capacity | 120-150kg/h, 200-250kg/h, 400-500kg/h, 1000-1200kg/h |

| 4 | Machine material | Stainless steel |

| 5 | Products | This line can produce various taste pet food, and the raw materials can be extruded into various shapes by the mold by adjusting the parameters. |

Advantages of fish feed production line

1.Cost Advantage

(1) Automation reduces labor costs

The automaticfish feed manufacturing line relies on PLC intelligent control systems and sensor technology to achieve full automation of the entire process from raw material transportation, ingredient mixing, granulation and molding to packaging and warehousing. Compared with traditional manual production lines, the labor demand is greatly reduced. Taking a medium-sized production line as an example, only 3-5 technicians are required to monitor equipment operation and handle abnormal situations in the automated mode, which reduces the labor configuration by about 70% compared with the traditional method. In addition, automated operation avoids production efficiency fluctuations caused by manual fatigue and operational errors, and there is no need to frequently conduct new employee training, further reducing long-term labor costs.

(2) Durable, low consumption and low maintenance

Core equipment such as pelletizers and extruders are made of high-strength alloy materials. The die and roller of the pelletizer are carburized and quenched, and the service life is extended to 2-3 times that of traditional components. The equipment has a built-in intelligent fault diagnosis system. By real-time monitoring of parameters such as temperature, vibration, and current, it will immediately warn and automatically shut down once an abnormality occurs to prevent the expansion of the fault. The modular design facilitates the replacement of parts and reduces downtime for maintenance. Data shows that the mean time between failures (MTBF) of the automatic production line is 35% higher than that of the traditional production line, and about 25% of the equipment maintenance cost can be saved each year.

2. Benefit advantages

(1) High yield meets demand

The automatic fish feed production line adopts a continuous production mode with strong production capacity. The output of a small production line can reach 1-3 tons per hour, and the output of a large production line exceeds 10 tons per hour, which can fully meet the feed needs of large-scale aquaculture enterprises. The equipment has a quick production change function. It only takes 20-30 minutes to complete parameter adjustment and mold replacement from juvenile feed to adult fish fattening feed, reducing production gaps. With 24-hour continuous operation, the annual output is about 40% higher than traditional intermittent production.

(2) Flexible market expansion

The production line is equipped with flexible and adjustable production modules and diversified molds, which can produce pellet feeds with different particle sizes ranging from 0.5 to 8 mm to meet the needs of various growth stages from fry to adult fish. At the same time, by adjusting the raw material formula and puffing process, various types of feeds such as sinking, floating, and slow-sinking can be produced. The intelligent control system supports rapid switching of production formulas, allowing enterprises to respond to market changes in a timely manner, develop functional feeds such as anti-stress and immune enhancement, expand product categories, and enhance market competitiveness and profit margins.

About Us

We are a professional manufacturer of food machinery and we have been manufacturing nutrition cereal bar processing line for nearly 20 years. In addition to the Nutrition Cereal Bar snack processing line, we also manufacture lines for deep-fried food, pet feed, modified starch and many more. Each of our lines has basically a variety of moulds, which can be adapted to produce a wide range of food products. We are not satisfied with the status quo but are constantly upgrading and innovating our products, adapting our production plans and designs to the changing needs of the times and keeping up with the pace of progress. Never satisfied with the pursuit of excellence!

Our Services

1. Recipe: The company's after-sales service department can provide free basic recipes or introduce more marketable recipe experts.

2. Training: after the installation and commissioning of the equipment can be on-site training of relevant operators, equipment easy to operate.

3. Return visit: regular after-sales telephone call back to customers, to help you solve the relevant problems encountered in the use of equipment.

4. Maintenance: our company provides quality and inexpensive spare parts to the demand side all year round, and provides equipment upgrades and new product development support, really let you have no worries.

5. Out of warranty maintenance: the company provides free maintenance for equipment damage caused by non-human factors during the warranty period. If the equipment is damaged due to human factors and force majeure, the company will provide maintenance services but charge the relevant fees.