Automated Energy-Efficient Soft Biscuit Production Systems for Premium Quality

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/Foodextruderfactory/

What are soft biscuit?

Softbiscuits are a type of baked biscuits with a hardy taste and light texture. It uses low-gluten flour as the main raw material. In order to achieve a hardy taste, the fat content in the formula is relatively high, usually accounting for 30%-50% of the flour, and some are even more. During the production, the amount of sugar added is also relatively large, generally 30%-40% of the flour. Sugar not only adds sweetness, but also helps to form the hardtexture and golden color of the biscuits.

Its production process is unique. It uses a cold powder process, that is, when preparing the dough, there is no need to preheat the flour and other raw materials in advance, and the various raw materials are directly mixed and stirred. During the mixing process, the time and strength must be strictly controlled to prevent the dough from forming too much gluten, so as to ensure the hardtaste of the biscuits. After the dough is prepared, it is made into biscuits through processes such as rolling, molding, and baking. The baking process has strict requirements on temperature and time control. Proper baking can give the biscuits an ideal color and hardness.

Hardbiscuits come in a variety of shapes, including round, square, and animal shapes, and have a richer flavor. In addition to the cream and fruit flavors mentioned in the article, there are also chocolate, matcha, salty, etc. They can meet the taste preferences of different consumers and occupy an important position in the field of casual snacks.

Soft biscuits are representative baked foods characterized by high fat and low gluten. They are typically hardy and melt in the mouth. They are commonly found in high-end snacks such as butter cookies and Danish cookies. These biscuits focus on sensory enjoyment and are usually served as afternoon tea snacks or gifts. Hard biscuits are long-lasting foods based on low fat and high gluten. They have a hard and dense texture and an ultra-long shelf life. They are mainly used in special scenarios such as military dry food, emergency reserves and pet food.

The difference between hard biscuits and soft biscuits

Soft biscuits are representative baked foods characterized by high fat and low gluten. They are typically hardy and melt in the mouth. They are commonly found in high-end snacks such as butter cookies and Danish cookies. These biscuits focus on sensory enjoyment and are usually served as afternoon tea snacks or gifts. Hard biscuits are long-lasting foods based on low fat and high gluten. They have a hard and dense texture and an ultra-long shelf life. They are mainly used in special scenarios such as military dry food, emergency reserves and pet food.

Introduction of soft biscuit production line

The full automatic soft biscuit making machine, developed independently by absorbing Japanese technology , has a novel design, compact structure and high degree of automation, from feeding, rolling, biscuit forming, waste recycling, drying, coating and cooling all at once. The Loyal company provides hundreds of molds and dozens of recipes for users. By chang ing the molds and recipes, it can produce popular high-end biscuits such as cream biscuits,cookies, thin biscuits, soda bis. cuits, animal biscuits,vegetables biscuit etc

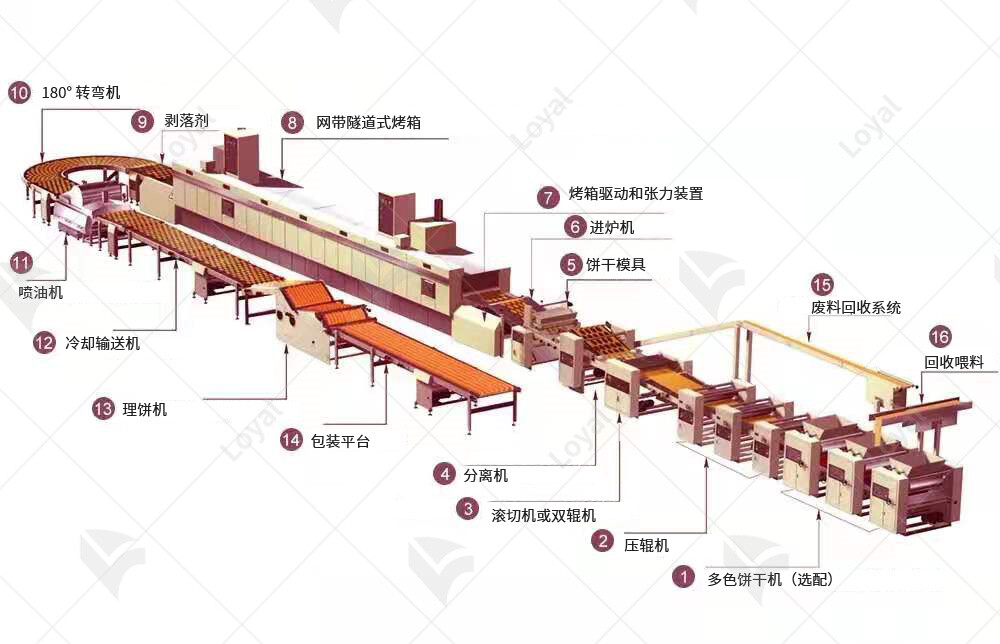

Equipment list of soft biscuit productionline

dough mixer-compound rolling and shaping machine-oven-oilsprayer- cooling machine-sorting machine-packaging machine

Production line Parameters of soft biscuit processing line

Host Model | LY280 | LY400 | LY600 |

Power and voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ |

Installed Capacity | 55KW | 110KW | 220KW |

Baking temperature | 200-300ºC | 200-300ºC | 200-300ºC |

Production capacity | 100kg/h | 150-200kg/h | 300-500kg/h |

Production line length | 30000mm | 43000mm | 60000mm |

Key technology for softbiscuitsproduction line

1.Ingredients

The formation of the unique taste of crispy biscuits depends largely on its special combination of ingredients. In the ingredient link, a high proportion of fat is an indispensable element. Fat not only gives biscuits a rich and mellow flavor, but also plays a key role in the construction of dough structure. It is like a "lubricant" for dough, making the dough texture softer and more delicate, and effectively reducing the toughness of the dough.

Sugar also occupies an important position in the formula. On the one hand, sugar can bring pleasant sweetness to biscuits and satisfy consumers' taste enjoyment; on the other hand, it will undergo a caramelization reaction during the baking process, making the surface of the biscuits form an attractive golden color, adding visual appeal.

2. Mixing

In the mixing process of crisp biscuit dough, it is extremely important to avoid excessive stirring. Excessive stirring will cause excessive gluten formation in the dough, resulting in increased toughness and elasticity of the dough, and ultimately make the biscuits taste harder and lose the loose characteristics that crisp biscuits should have.

Generally speaking, the weighed oil and sugar are first stirred and mixed. This step can make the sugar evenly dispersed in the oil to form a delicate sugar-oil mixture, laying the foundation for the uniformity of the subsequent dough. The stirring speed should not be too fast, and the time should also be strictly controlled. Usually, stir at a low speed for 2-3 minutes until the sugar and oil are fully integrated and the texture becomes light and fluffy.

Next, gradually add low-gluten flour. At this time, you can use a scraper to stir or stir at a low speed to fully combine the flour and sugar-oil mixture. During the stirring process, closely observe the state of the dough. When the dough is just formed and is in a relatively loose and non-sticky state, stop stirring immediately. The entire mixing process should be as gentle and quick as possible to prevent the dough from gluten.

3. Molding

Roller printing is one of the more common molding methods in the production of crisp biscuits. This method is completed with the help of a roller printing machine. The surface of the roller printing machine mold is engraved with various exquisite patterns. When the dough passes through the roller printing machine, the mold will emboss the corresponding shape on the surface of the dough and cut the dough into individual biscuit blanks. The advantage of this molding method is that it can efficiently and accurately produce biscuit blanks with uniform shapes and specifications. In the molding process, the pressure on the dough is relatively uniform, which is conducive to maintaining its loose structure and ensuring the crisp taste of the finished biscuit.

Extrusion molding uses an extruder to extrude the dough through a mold of a specific shape to form biscuit blanks of various shapes. Extrusion molding is suitable for making some biscuits with more complex and unique shapes, such as cartoon shapes, letter shapes, etc.

4. Baking

The baking process plays a decisive role in the quality of crisp biscuits. The low-temperature slow baking method is adopted, and the baking temperature is usually controlled between 150-180℃. This is because at a lower temperature, the moisture inside the biscuit can evaporate slowly, and the various components in the dough have enough time to react chemically, such as gelatinization of starch and denaturation of protein, so that the biscuits gradually expand, set, and form a crispy taste.

If the baking temperature is too high, the surface of the biscuit will harden quickly, and the internal moisture cannot be discharged in time, resulting in the formation of cavities inside the biscuit and a rough taste; at the same time, too high a temperature can easily cause the surface of the biscuit to burn, affecting the color and flavor of the product. Low-temperature slow baking can effectively avoid these problems, so that the biscuits are heated evenly during the baking process, and the internal and external quality is balanced. In terms of baking time, it is generally necessary to make appropriate adjustments according to the size, thickness and performance of the biscuits, usually 15-30 minutes.

5. Cooling

After baking, the biscuits need to be naturally cooled to room temperature. This process seems simple, but it actually has an important impact on the quality of the biscuits. Natural cooling can further stabilize the internal structure of the biscuits, avoid thermal expansion and contraction caused by rapid cooling, and thus prevent the biscuits from breaking.

During the cooling process, the biscuits should be placed in a well-ventilated and dry environment to prevent the biscuits from being affected by humid air and becoming soft. At the same time, be careful to avoid squeezing and colliding the biscuits against each other to avoid damaging the shape of the biscuits. Generally speaking, the time required for biscuits to cool to room temperature varies depending on the ambient temperature and humidity, usually about 30 minutes to 1 hour. After the biscuits are completely cooled, they can be packaged to maintain the crisp taste and freshness of the biscuits.

Advantages of crisp biscuit production line

(I) Manual operation easily leads to over-kneading of dough

In the traditional process of making crispy biscuits, manual operation occupies a dominant position. However, manual operation has certain limitations, especially in the dough mixing stage. It is difficult to accurately control the strength and time of manual stirring, and it is easy to cause the dough to become gluten due to over-kneading. Once the dough becomes gluten, the taste of the biscuits will become hard, and the crispy and loose taste of crispy biscuits will be lost, which seriously affects the product quality. This problem of unstable product quality caused by differences in manual operation is particularly prominent in large-scale production, which increases the difficulty and cost of product quality control.

(II) Imprecise control of baking temperature

Precise control of baking temperature is crucial to the quality of crispy biscuits. However, in actual production, traditional baking equipment often finds it difficult to achieve precise temperature control. The temperature inside the oven may be uneven, resulting in inconsistent baking degrees of biscuits in the same batch. Some biscuits may be burnt, while others may not be fully cooked. In addition, slight changes in environmental factors during baking, such as the number of times the oven door is opened and the fluctuation of the outside temperature, may affect the temperature inside the oven, further increasing the difficulty of temperature control. This problem of inaccurate baking temperature control will not only cause product waste, but also affect the company's production efficiency and economic benefits.

Why Choose Us

We are a professional manufacturer of food machinery and we have been manufacturing nutrition cereal bar processing line for nearly 20 years. In addition to the Nutrition Cereal Bar snack processing line, we also manufacture lines for deep-fried food, pet feed, modified starch and many more. Each of our lines has basically a variety of moulds, which can be adapted to produce a wide range of food products. We are not satisfied with the status quo but are constantly upgrading and innovating our products, adapting our production plans and designs to the changing needs of the times and keeping up with the pace of progress. Never satisfied with the pursuit of excellence!