Application Of Microwave In Industrial Industry

Microwaves are electromagnetic waves that penetrate into an object and heat it up. Microwave is a very high frequency electromagnetic wave, irradiated on the ideal conductive metal surface will be completely reflected. A small part of irradiation on the surface of the medium is reflected, and most of it can penetrate into the interior of the medium, and is gradually absorbed by the medium inside and converted into heat energy, the penetration depth is mainly determined by the dielectric constant of the medium and the frequency of electromagnetic wave. At microwave frequencies, the penetration depth of the average object can be several centimeters. Microwave also has a biological effect on organisms, which can inhibit and kill cells and bacteria under certain conditions.

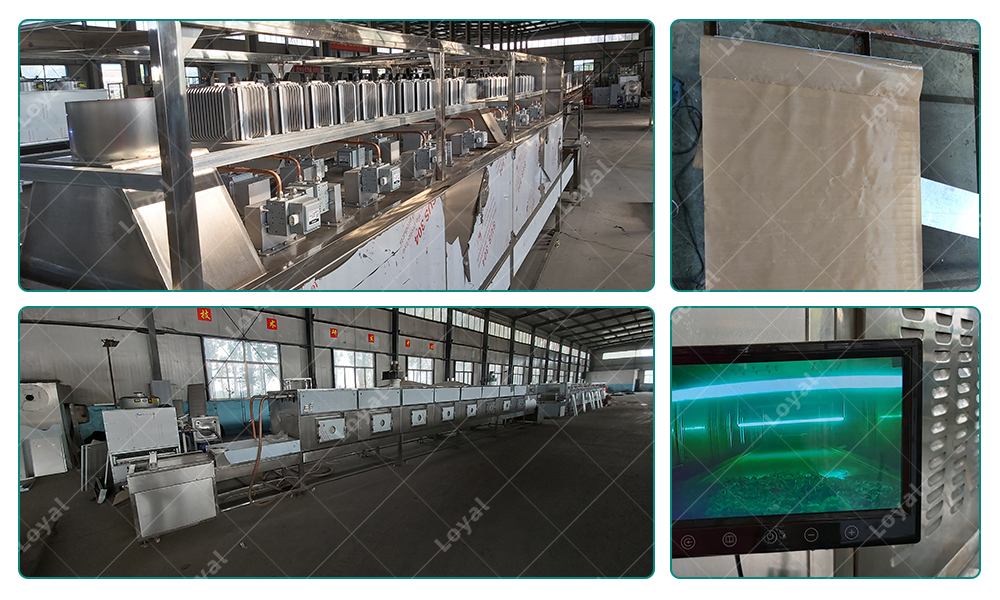

The microwave heating system consists of an electromagnetic wave generator and a metal heating chamber which can reflect microwaves to the object being heated. Modern microwave heating stoves usually have a circular section of the furnace, which is designed to heat more evenly than a type furnace. In addition to single microwave heating, there are compound heating furnaces. Microwave heating in combination with other forms of heating, or several different frequencies of microwave heating. Microwave ovens combined with hot air can be used to heat or dry materials. This kind of heating furnace is most suitable for high temperature, large material flow, and high cost of microwave heating only.

What’s Characteristics Of Microwave Heating

1.Fast Heating Speed

Conventional heating, such as flame, hot air, electric heating and steam, all use the principle of heat conduction to transfer heat from the outside of the heated object to the inside, and gradually increase the central temperature of the material, which is called external heating. It takes a certain amount of time for the center to reach the desired temperature, and longer for materials with poor thermal conductivity.

Microwave heating is to make the heating substance itself into a heating body, called the internal heating method, does not need the process of heat conduction, internal and external heating at the same time, so it can achieve the effect of heating in a short time.

2.Heat Evenly

Conventional heating, in order to improve the heating speed, it is necessary to increase the heating temperature, which is easy to produce the phenomenon of external coke. When heated evenly by microwave, all parts of the object, regardless of their shape, can generally penetrate evenly into the microwave to generate heat. So the uniformity is greatly improved. It can avoid the phenomenon of inner coke, outer dry and inner wet. It improves product quality and is conducive to the formation of food material quality.

3.Energy Efficient

In microwave heating, the microwave energy can only be attracted by the heating object itself and generate heat. The wall of the heating chamber, the air in the heating room and the corresponding container will not heat, so the thermal efficiency is very high, and the production environment is also significantly improved. Energy-saving and efficient microwave has different effects on different substances. When microwave is heated, the heated material is generally placed in the heating chamber made of metal. The heating chamber is a closed cavity for microwave, and the microwave can not be leaked out. The external heat loss is less, can only be absorbed by the heating object, the air in the heating chamber and the corresponding container will not heat, no additional heat energy loss, so the thermal efficiency is very high; At the same time, the workplace environment will not be elevated, environmental conditions are significantly improved. So energy saving, electricity saving, generally can save 30% - 50%.

4.Easy To Control

To realize the automatic production of microwave heating and drying equipment as long as the operation control control knob can instantly achieve the purpose of lifting and stopping. Because in heating, only the object itself heats up, the furnace body, the air in the furnace are no waste heat, so the thermal inertia is very small, no heat loss, the application of microcomputer control can automatically monitor the product quality, especially suitable for the

automatic control of the heating process and heating process specifications.

5.Low Temperature Sterilization, No Pollution

Nutritional microwave sterilization is through the joint action of thermal effect and non-thermal effect (biological effect), so compared with conventional thermal sterilization, it has the characteristics of low temperature and short time sterilization. Therefore, it is not only safe and safe, but also can keep the nutritional components of food from being lost and destroyed, which is conducive to maintaining the original quality of products, with less loss of color, aroma, taste and nutrients, and extremely beneficial to the maintenance of vitamin C and amino acids. Experiments have shown that sun-dried fresh vegetables can retain only 3% of their chlorophyll, vitamins and other nutrients, while sun-dried vegetables can retain 17%, hot air drying can retain 40%, microwave drying can retain 60-90%, microwave sublimation drying can retain 97% of fresh vegetables.

6.Selective Heating

Microwaves have different effects on substances of different properties. Microwave has different effects on materials with different properties. Because water molecules can absorb microwave best, the part with high water content absorbs microwave power more than the part with low water content. The ability of water in the material to absorb microwave is stronger than that of the dry matter, so the heat of water is higher than that of the dry matter, which is conducive to the rise of water temperature, promote the evaporation of water, and also conducive to the overheating of the dry matter, which is very beneficial to reduce the destruction of nutrition and flavor. Can automatically absorb microwave balance, avoid material heating and drying coking.

7.Improve Working Conditions

Microwave heating equipment no waste heat, no sample pollution problem, easy to meet the requirements of food hygiene, and itself does not heat, no radiation heat, so greatly improve the working conditions, and the equipment structure is compact, save plant area.

To sum up, the use of microwave heating technology has the advantages of fast, maintain nutrition and flavor, uniform, disinfection and sterilization, energy saving, health, safety, no pollution, high efficiency, convenient, controllable, small investment, conducive to improving product quality, prolong shelf life, improve labor conditions, realize production automation and so on, is an advanced technology worth promoting.

What’s Application Of Microwave Heating

The application of microwave technology provides a new heating method for industrial heating, which is widely used in industry, agriculture, chemical industry, medical treatment and other aspects. One is the use of its thermal effect, mainly used for food, medicinal materials, agricultural and sideline local products, wood, cardboard, chemical industrial products and other heating and drying. The second is to use its biological effect, food, medicinal materials, agricultural and sideline soil products and other low temperature sterilization, mildew preservation, liquor aging, alcoholization, stop fermentation, breeding, etc. Now as a high technology, microwave heating has been from laboratory to practical production, the prospect is very broad.

1.Can Reheat And Defrost Refrigerated Food

Thawing: rewarming " means increasing the temperature of a frozen food from a deep freezing state to a value below zero. Generally about-5℃, at this time the food can be sliced, segmentation. Thaw must raise the temperature to room temperature or above 0℃ to take the food out of the freezing state. The use of microwave techniques has many outstanding advantages over conventional methods. For example, the processing time is greatly shortened, easy to control, product quality is good, color and freshness can be maintained, less nutrition and water loss, low bacteria content, efficient and low cost, less energy consumption, small area, working conditions and environment have been improved.

2.To Extend The Shelf Life Of Food

In order to prevent food deterioration, for long-term preservation, people will use a variety of methods of sterilization and mildew prevention, but there are such or such difficulties and problems, the use of microwave sterilization and mildew prevention is a more ideal method. Compared with conventional methods, it can keep food with better taste, color and nutrition, and has great potential in liquid beverage treatment.

3.Sterilization And Disinfection Treatment

Using microwave to small packages of cooked food, tourism food, cakes, preserved fruit and other heating, sterilization and disinfection treatment, most of this kind of food to eat convenient to carry, safe and hygienic, with a certain shelf life. For this reason, many production plants to add preservatives, etc., to extend the shelf life. And after the use of microwave treatment can be without preservatives, which brings benefits to manufacturers, businesses, consumers.

4.Polymolecular Compounds Can Be Thermoformed

5.Heat Food

Food industry is the pillar industry of the rapid rise. Microwave can be used to expand, dry, remove fishy and keep fresh of food. It is used in the production of pastries, beef jerky, potato chips, dried fillets, salted duck, cashews, peanuts, melon seeds, soybeans, etc.Many families use microwave to heat food.

6.Drying Food, Wood, Paper, Film And Other Coating Materials

7.Food industry

Box lunch microwave heating sterilization; Microwave drying and sterilization of sunflower seeds, walnuts and peanuts; Microwave drying and sterilization of food. Summer fresh milk, licking wine, cakes, sandwiches and other food is easy to go bad, if you put it in the microwave oven for 10-20 seconds, can extend twice the preservation time, but also can play the role of disinfection and sterilization.

8.Making Dried Flower Tea And Fruit

This process is mainly done in the country of origin. Usually by sun drying or hot air drying method, according to the local technical level. With this method, the ingredients need to be processed at low temperatures for a long time in order to preserve their shape and taste. And microwave drying can realize continuous processing, short time, keep color and taste, improve the processing amount. At the same time, microwave heating can also achieve the effect of sterilization.

9.Wood Processing

microwave can be on the 1-6 cm thick wood for uniform, rapid drying thousands, drying only ten minutes, and no cracking, deformation is small, at the same time to kill the eggs and larvae inside the wood; Can also be cured of plywood or plywood bonding; Bamboo products drying, mildew sterilization. The microwave equipment produced by the company is widely used in metallurgy, chemical industry, ceramics, refractory materials, wood processing and other industrial fields of high energy consumption, heavy pollution and fine processing of new materials.

10.Insecticidal Sterilization

Microwave can be used in low temperature sterilization and insecticidal, processing food, medicine, tobacco, wood, etc. At 70~8O℃, it can play the role of insecticidal sterilization, and the heating speed is fast, not affected by the thickness and shape of the material.

11.Ceramic Sintering

Microwave can be uniformly densified ceramic sintering, the highest temperature up to 2000℃, to obtain large size fine ceramics.

12.Chemical Industry

Microwave is widely used in chemistry, such as microwave digestion, extraction, hydrolysis, catalytic reaction; chemical powder microwave drying; leather microwave drying;chemical fertilizer microwave drying.

13.Pharmaceutical Industry

Microwave drying of Chinese medicinal materials and pills.

14.Rubber Industry

Rubber microwave vulcanization; Silicone is vulcanized.

Parameter Of Our Microwave Drying Equipments

Model |

Size(L*W*H)

| Output Power (Kw) | Dewaterability | Sterilization Capacity | Baking And Roasting Capacity |

HN-10KW | 5000mm*825mm*1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

HN-2OKW | 8000mm*825mm*1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

HN-3OKW | 8500mm*1160mm*1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

HN-40KW | 10000mm*1160mm*1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

HN-5OKW | 12500mm*1160mm*1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

HN-60KW | 13500mm*1450mm*1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

HN-7OKW | 13500mm*1500mm*1750mm | ≥70KW | 70KG/Hour | 7000KG/Hour | 210-350KG/Hour |

HN-8OKW | 13500mm*1650mm*1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

HN-100KW | 16800mm*1650mm*1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

HN-150KW | 22400mm*1850mm*1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

Microwave Heating Function

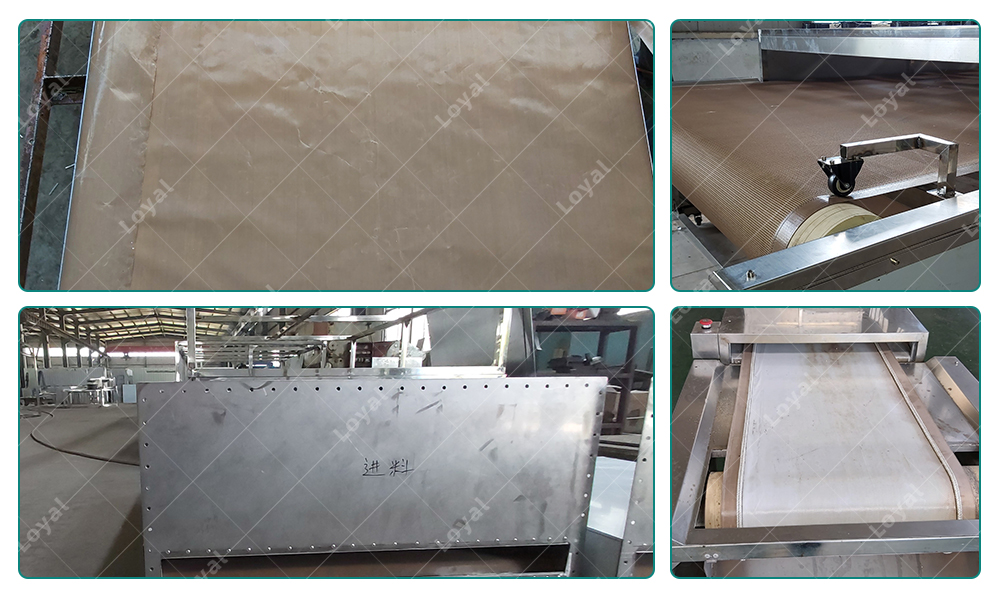

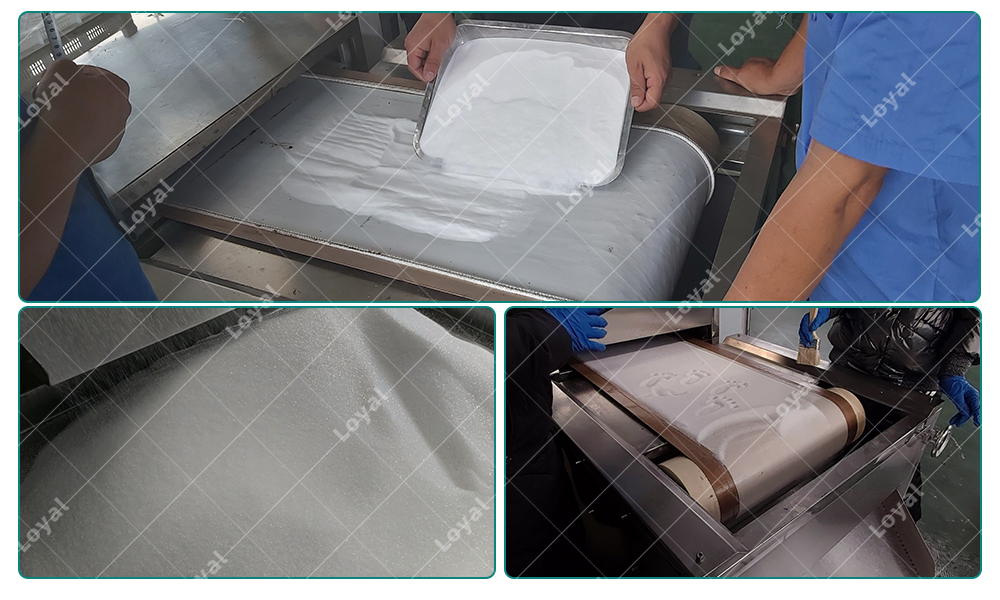

Microwave drying equipment uses microwave energy to dry various materials. The main function of microwave drying equipment is to remove moisture in materials quickly and efficiently.

The device works by generating microwave energy and directing it towards the material being dried. The material absorbs microwave energy, causing the water molecules in it to vibrate rapidly, generating heat. This heat then vaporizes the water, which is then removed from the drying chamber.

Microwave drying equipment is used in food processing, pharmaceutical, chemical and textile industries. It is particularly suitable for drying materials that are sensitive to high temperature or require specific moisture content.

Microwave drying equipment not only has drying function, but also can provide sterilization, preservation and other benefits of drying materials. Microwave energy can effectively kill bacteria and other microorganisms, making it a useful tool for sterilizing materials. It also helps preserve the color, flavor and nutrients of the food during the drying process.

Overall, the function of microwave drying equipment is to provide a fast, efficient, and versatile way to dry a variety of materials while maintaining their quality and integrity.