Advantages of crumb making equipment and its operation

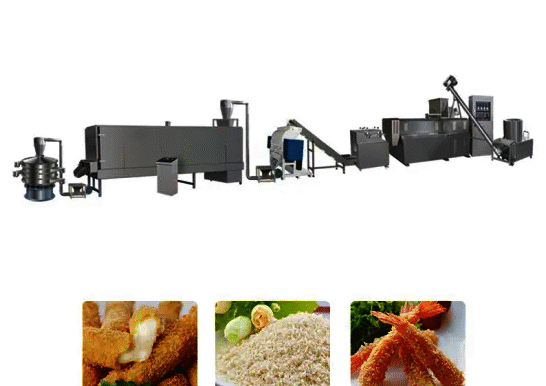

Bread Crumbs Production Line is a new type of production equipment that is specially developed and manufactured to produce bread crumbs. It can produce delicious, healthy, and safe bread crumbs of various types, and it is commonly used in food processing plants and is greatly recognized. Many people may not be too familiar with Bread Crumbs Production Line, so today, we will talk about its advantages and operation methods.

Bread Crumbs Production Line adopts cereal flour, rice flour, corn flour, corn starch, soybean flour, etc., as raw materials, grinds and crushes the raw materials and then mixes them, dries them after extrusion by extruder, produces high-quality bread crumbs, and then cools and packs them. The bread crumbs production line is highly automated from raw material, puffing, baking, drying to finished products.

Advantages of Bread Crumbs Production Line.

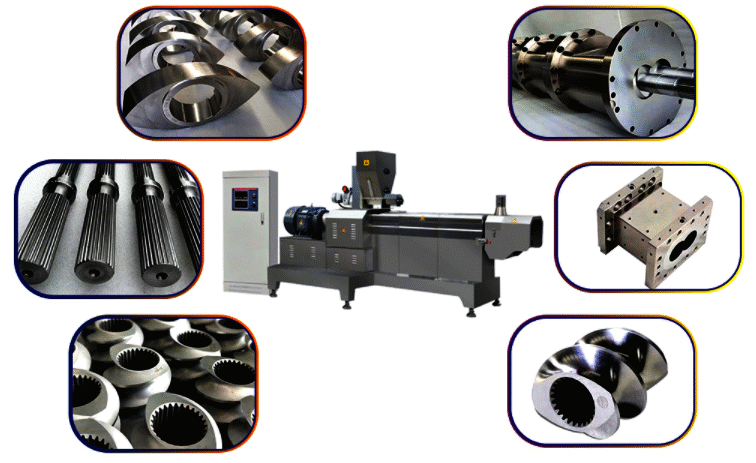

1、The whole equipment is made of stainless steel, with a novel design and beautiful appearance.

2、The machine is made of the most advanced parts, and the whole production line is complete with all parts and perfect structure.

3、The screw has a self-cleaning function, no need to disassemble when shutting down, easy to clean, and strong self-cleaning ability.

4、The production process of the equipment is strictly controlled, with reliable quality, superior performance and no pollution.

5、The high degree of automation and simple operation of the equipment can greatly save manpower and improve work efficiency.

We have finished introducing some of the outstanding features of Bread Crumbs Production Line, mainly including the overall beauty, perfect structure, strong self-cleaning ability, superior performance, and a high degree of automation. During the processing of the Bread Crumbs Production Line, special attention should be paid to the correct operation method of the equipment to prolong the service life of the machine.

Operation of the bread crumb processing machine:

1、Before use, attention should be paid to checking the working condition of each part of the equipment and whether there is any damage, discharging the equipment in time to ensure the smooth progress of the production process. Attention should also be paid to check whether there is any air and water leakage in the piping system, and if there is, it should be solved in time.

2、Before the formal operation, perform a trial operation first and run it for a few minutes to check whether the various components can operate normally. If there is no malfunction, then go to the formal use.

3, When placing raw materials on the conveyor belt, pay attention not to put too much not to affect the processing effect, and the raw materials after use cannot be parked on the conveyor belt. They must be processed in time to avoid affecting subsequent work.

4, After the equipment is used for a while, pay attention to the use of gears, sprockets, ratchets, and other parts, add lubricant in time, and pay attention to the appropriate amount when adding.

5, After the equipment is usually used and operated, pay attention to the cleaning of the equipment and clean up all corners of the machine to avoid residual residue and rot after a long time.

The above are the advantages of Bread Crumbs Production Line and its use in the process should pay attention to the problem, and I hope it will be of some help to you. If there are other things you want to know, you can pay more attention to us and contact us directly. Here, you will get the answer you want.