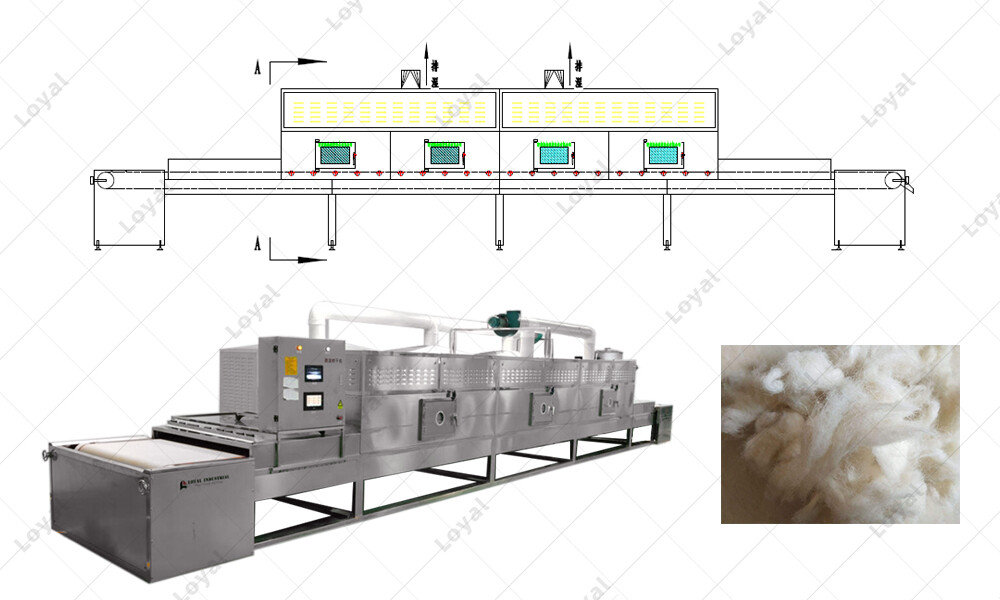

Wool Drying Microwave Oven

Description Of Wool Drying Oven

Wool drying oven is a special equipment for drying wool products such as yarn, fabric and clothing in the textile industry. Ovens provide controlled heat and airflow to remove moisture from the wool material and speed up the drying process, which is critical to maintaining the quality and appearance of wool products. Wool drying ovens are usually made of durable materials such as stainless steel, aluminum or iron to withstand high temperatures and prolonged use. They may have multiple height-adjustable drying racks or racks to accommodate wool products of different sizes and shapes. The oven operates through a combination of electric heating elements and a powerful blower to circulate hot air evenly throughout the drying chamber for uniform drying. Temperature and airflow are carefully controlled with a thermostat and adjustable vents to prevent overheating and damage to wool products. Overall, a wool drying oven is an essential tool for textile manufacturers who want to efficiently and effectively produce high quality wool products.

How To Dry The Wool

1.Prepare the fleece to dry by toweling off excess moisture or gently squeezing.

2.Set the oven temperature according to the recommended temperature for the type of wool being dried. In general, the temperature should be kept below 140°F to prevent damage to the wool fibers.

3.Place the woolen items in the oven, making sure there is enough space between them for air circulation.

4.Set the timer for the recommended drying time for the wool product you are drying. In general, drying time can range from 1-4 hours, depending on the type and thickness of wool.

5.Monitor the temperature and airflow during the drying process to ensure that the wool product is dried evenly without excessive heat.

6.After wool products are dry, remove them from the oven and allow them to cool before handling or packaging.

7.Store dried wool products in a dry and cool place away from direct sunlight or heat sources.

NOTE: It is important to always follow the specific instructions provided by the wool manufacturer and oven manufacturer to ensure the best results and avoid any damage to the wool product.

Working Principle Of Industrial Microwave Wool Oven

Industrial Microwave Wool Ovens use microwaves to generate heat to dry wool products evenly. Microwaves are electromagnetic waves with a frequency of about 2.4 GHz that excite water molecules in wool. This excitation causes the water molecules to spin, creating heat that dries the wool quickly. The industrial microwave wool oven consists of a metal chamber containing wool products and a microwave generator that generates microwave energy. Microwave energy directly enters the chamber, and the amount of energy is controlled by the controller of the oven to adjust the temperature in the chamber. The wool product in the chamber is placed on a conveyor belt which slowly moves the wool through the oven. This ensures that the wool product is evenly exposed to the microwaves and dried evenly. The oven's controller can be programmed to adjust the temperature and drying time according to the type, thickness and amount of wool product being dried. Drying times are usually much shorter than traditional drying methods, and the wool product is dry and fluffy. Overall, the industrial microwave wool oven is an efficient and effective way to use microwave energy to generate heat to dry wool products quickly and evenly.

Microwave Wool Dryer's Advantage

Faster Drying Time | The industrial microwave wool dryer can dry wool products faster than traditional methods. The heat generated by the microwaves penetrates the wool fibres, drying the wool from the inside out. This can significantly reduce drying time, resulting in faster turnaround times and increased productivity. |

Better Quality | Microwave energy acts on wool products in the dryer, which is evenly distributed and dried evenly. This results in a premium wool product that is softer, loftier and has better color retention. |

Energy Efficiency | The Industrial Microwave Wool Dryer uses energy efficient technology to generate heat, which reduces energy costs and carbon footprint. |

Reduce Labor Costs | Compared with traditional drying methods, industrial microwave wool dryers require the least labor. The dryer is automated and can run continuously, reducing the need for manual labor. |

Reduced Risk Of Damage | Traditional wool drying methods can involve high temperatures and mechanical stressors that can damage the wool fibers. The heat generated by the Industrial Microwave Wool Dryer is gentle, reducing the risk of damaging the wool product. |

Wool Product Display

Wool products can be made from fibers from sheep, goats and even rabbits. They are popular for their natural properties including insulating, breathable and moisture-wicking abilities. Here are some examples of wool products:

Clothing | Wool is commonly used to make clothing such as sweaters, jackets, trousers and socks. Wool clothing keeps you warm without being too bulky, making it a popular choice for outdoor activities and winter sports. |

Bedding | Wool is also used to make bedding such as blankets, quilts, pillows and mattress covers. Wool bedding provides natural insulation while also wicking away moisture to keep sleepers warm and dry. |

Rugs And Rugs | Wool is a popular material for rugs and rugs because of its durability, softness, and natural stain resistance. Wool rugs and rugs are also easy to clean and maintain. |

Yarn | Wool can also be spun into yarn for knitting, crocheting, weaving, etc. Wool yarn is used to make a variety of items such as clothing, blankets and home decor. |

Industrial Application | Wool fiber can also be used for industrial purposes such as insulation and sound insulation. These fibers can be bonded together to make a strong block that can be used in insulating or sound-absorbing panels. |

In conclusion, wool is a versatile material that can be used in everything from clothing to industrial applications. Its natural properties make it a popular choice for many consumers looking for an environmentally friendly and sustainable product.