What is Instant Noodles Production Line?

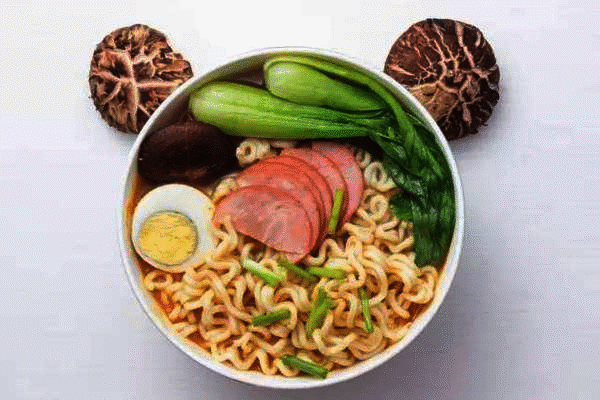

The accelerated pace of life has made people rely more and more on instant food, among which instant noodles have been unanimously recognized by consumers for their convenience and unique taste and have always occupied the top of the list of instant food in the market.

Fast food is suitable for the needs of modern life, and instant noodles have become mainstream food. With the huge market demand, more and more manufacturers have started to produce instant noodles, and the competition has become more and more fierce. Instant Noodles Production Line is a very recognized equipment that can help manufacturers to improve production efficiency and quality.

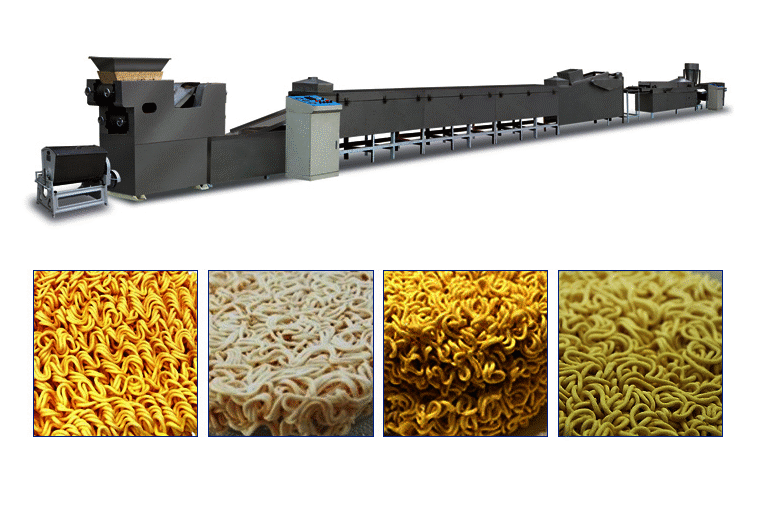

What is Instant Noodles Production Line?

Instant Noodles Production Line is professional equipment used to produce instant noodles, which is a combination of noodle making machine, forming machine, steamer, cutting machine, fryer, cooler, packing machine, and other equipment. The method of use is flexible and changeable. You can use one of the equipment or the entire production line. In addition, it can produce processed fried instant noodles, non-fried instant noodles, round instant noodles, square instant noodles, and many other types of instant food.

The uses of each equipment in the production line are as follows:

1. Mixing machine: the main function is to mix the dough, put the flour, salt, and other raw materials into the equipment according to the recipe of the pastry, add the right amount of water, and then mix it well to make it into a smooth dough.

2. Forming machine: The dough is conveyed into the machine, and the roller press will press the dough into a smooth pastry, and then the knife roller will cut the pastry into noodles. The thickness of the pastry and the thickness of the noodles are adjustable. At the same time, because the line speed of forming conveyor belt is low and the line speed of noodles is high, therefore, during the conveying process, the noodles will be subject to resistance and become curved and wavy, which can effectively increase the contact area with air. The time is shorter in the subsequent processing, and the time of consumer bubble noodles will also be effectively shortened.

2. Steamer: That is, steam is used to make starch gelatinized and protein denatured by heating, and mature noodles are made from raw noodles, and the noodles will be stretched during the steaming process.

3. Cutting machine: the equipment can cut the steamed noodles into a certain length, the relative rotation of the cutting knife and roller, while cutting the noodles will also be folded, forming the shape of the final instant noodles we see.

4. Fryer: High-temperature frying can make the instant noodles quickly dehydrated, on the one hand, to facilitate transportation and storage, so that on the one hand, it can prevent the α-chemical starch from regenerating, so that the instant noodles form a fixed shape.

5. Cooling machine: high-temperature frying of instant noodles after the temperature is high, direct packaging will be scalded bags, and packaging is also easy to return to moisture, no longer crisp, so the need for cooling treatment.

6. Packaging machine: This equipment can realize automatic packaging, from feeding, feeding, to bag making, sealing, and other processes that can be completed at one time, in which the seasoning package needs to be placed on the pastry and then packaged.

The various parts of the production line are coordinated so that the production can be automated. In the age of industrialization, automation means higher quality and production efficiency, which is significant for manufacturers.

In addition, the Instant Noodles Production Line is made of stainless steel, with high quality, smooth operation, 24-hour continuous processing, and a small footprint, so small and medium-sized enterprises can use it with confidence. The line has a very low price, with very high-cost performance, is the ideal choice for manufacturers to reduce production costs and improve economic efficiency. If you are looking for quality equipment to enhance your production quality, welcome to contact us, we will be happy to serve you!