What Are the Four Approved and Safe Methods for Thawing Food?

Thawing food correctly is not just a step in the cooking process; it's a crucial practice for ensuring the safety and quality of the food we consume. Improper thawing can lead to the growth of harmful bacteria, leading to foodborne illnesses that can be dangerous to health. The process of safely thawing food involves understanding the right methods to use that will not compromise the food's safety or quality.

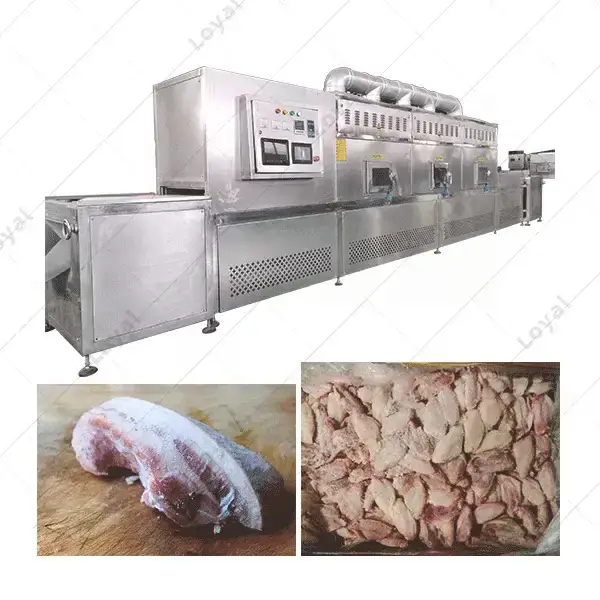

In professional settings, the stakes are even higher, given the volume of food handled daily. Here, Industrial Defrosting Equipment and Meat Defrosting Machines play a pivotal role. These pieces of equipment are designed to thaw large quantities of food quickly and uniformly, minimizing the risk of bacterial growth and ensuring that the food remains in the best possible condition for cooking and consumption. The integration of such technologies in the food industry marks a significant advancement in food safety and quality, highlighting the industry's commitment to consumer health.

Refrigerator Thawing

Thawing food in the refrigerator stands as the safest method for most types of food, especially for delicate items like meats, poultry, and seafood, which are susceptible to bacterial growth at room temperature. This method involves planning ahead, as it can take anywhere from several hours to a full day for larger items to thaw completely, depending on their size and density.

Importance of Planning Ahead

The slow process of refrigerator thawing demands foresight and planning. For instance, a large turkey may require up to 24 hours for every 5 pounds of weight to thaw safely in the refrigerator. This method's safety lies in its ability to keep food at a constant, safe temperature (below 40°F or 4°C), significantly reducing the risk of bacterial proliferation.

Benefits of Refrigerator Thawing

Refrigerator thawing is highly recommended by food safety experts for its ability to maintain food quality. "Keeping food at a safe temperature during the thawing process is critical to minimizing the risk of foodborne illnesses," states Dr. Angela Shaw, a food safety specialist. "Refrigerator thawing, while slower, ensures that food remains at a safe temperature, making it the preferred method for most items, especially high-risk foods like meats and seafood."

By incorporating refrigerator thawing into their food preparation routine, individuals and professionals alike can ensure that they are handling food safely, preserving its integrity and quality from the thawing process through to cooking and consumption. This method, despite its slower pace, stands as a testament to the adage that good things come to those who wait, ensuring food safety and quality are never compromised.

Cold Water Thawing

Cold water thawing provides a faster alternative to refrigerator thawing, suitable for situations where time is of the essence. This method involves submerging food in cold water, a process that accelerates thawing while still maintaining food safety. However, it requires careful attention to detail to ensure effectiveness and safety.

Step-by-Step Guide to Cold Water Thawing

- Ensure the Food is in a Leak-proof Package: To prevent water from absorbing into the food, which can affect texture and flavor, ensure the item is sealed in a leak-proof plastic bag.

- Submerge in Cold Water: Place the sealed food in a bowl or sink filled with cold water. The cold temperature is crucial for slowing bacterial growth.

- Change Water Regularly: Replace the water every 30 minutes to maintain a cold environment. This constant renewal of cold water facilitates even and effective thawing.

Effectiveness and Safety Considerations

Cold water thawing can significantly reduce thawing time compared to the refrigerator method, making it ideal for last-minute preparations. A pound of meat, for instance, can thaw in an hour or less. However, "It's imperative to keep the water cold and change it frequently to ensure food remains in a safe zone, away from temperature ranges where bacteria can thrive," advises Chef Marco Garcia, a culinary hygiene expert.

This method's safety and effectiveness hinge on diligence—regularly changing the water ensures the food thaws quickly without entering the danger zone of bacterial growth. While it requires more active participation than refrigerator thawing, cold water thawing strikes a balance between speed and safety, making it a valuable technique for both home cooks and professionals when time constraints are a factor.

Microwave Thawing

Microwave thawing stands out for its speed, offering the quickest method for thawing food when time is at a premium. Utilizing the microwave's energy to generate heat within the food, this method can thaw items in a matter of minutes. However, it's crucial to proceed with caution to ensure food is thawed safely and evenly.

Guidelines for Safe Microwave Thawing

- Use the Defrost Setting: Most microwaves come equipped with a defrost setting that lowers the power level, providing a more gentle thawing process. This setting helps reduce the risk of cooking the food on the outer edges while the inside remains frozen.

- Cook Immediately After Thawing: Because the microwave can partially cook some areas of the food during the thawing process, it's essential to cook the food immediately after thawing to prevent the growth of harmful bacteria.

- Stir or Rotate for Even Thawing: For foods that can be stirred or pieces that can be rotated, doing so midway through the thawing process can help achieve more uniform thawing.

Considerations for Microwave Thawing

Microwave thawing is particularly suited for small cuts of meat, poultry, and seafood, as well as for pre-cooked foods that just need to be warmed up. "The microwave can be a powerful tool for thawing, but it's important to understand its limitations," notes Dr. Luis Fernandez, a food technology researcher. "Not all foods thaw well in the microwave, especially larger items or those with uneven shapes, so selecting the right foods for microwave thawing is key."

While microwave thawing offers unparalleled speed, it demands attentive handling to ensure food safety and quality. This method is best reserved for situations where rapid thawing is needed, and the food will be cooked immediately thereafter, ensuring any potential bacteria are destroyed in the cooking process.

Using Industrial Defrosting Equipment

For commercial kitchens, food processing plants, and other large-scale food service operations, Industrial Defrosting Equipment and Meat Defrosting Machines offer a solution for thawing large quantities of food rapidly and uniformly. These specialized machines are designed to handle the demands of high-volume food preparation, ensuring that food is thawed safely and ready for cooking or further processing in a fraction of the time it would take with traditional methods.

Introduction to Industrial Defrosting Equipment

Industrial Defrosting Equipment utilizes advanced technologies, such as radio frequency or ultrasonic waves, to accelerate the thawing process without compromising food safety or quality. Similarly, Meat Defrosting Machines are specifically tailored for thawing various types of meat, from beef and poultry to fish, efficiently and uniformly.

Advantages of Using Specialized Equipment

- Speed and Efficiency: These machines can thaw food much faster than manual methods, crucial in a commercial setting where time is money.

- Uniform Thawing: Advanced technology ensures that food is thawed evenly, eliminating cold spots where bacteria can grow.

- Safety and Quality: Designed with food safety in mind, these machines maintain the integrity of the food, preserving its texture, flavor, and nutritional value.

"Utilizing Industrial Defrosting Equipment in a commercial setting not only enhances operational efficiency but also significantly improves food safety standards," explains George Miller, a food safety consultant. "The technology behind these machines is designed to ensure that food is thawed safely, maintaining its quality for the consumer."

For businesses that handle large volumes of food, investing in Industrial Defrosting Equipment or a Meat Defrosting Machine can be a game-changer. These machines streamline the thawing process, ensuring that food service operations can run smoothly and efficiently, with a consistent focus on producing high-quality, safe food for consumers.

Comparison and Best Practices

When selecting the best method for thawing food, it's essential to consider the specific needs of your operation, including the type of food, the quantity, and the time available. Each thawing method—from refrigerator thawing to using Industrial Defrosting Equipment—has its advantages and ideal applications. Here's how they compare:

Safety and Time Efficiency

- Refrigerator Thawing is the safest method, ideal for maintaining quality and minimizing bacterial growth, though it requires the most time.

- Cold Water Thawing offers a faster alternative but requires active management to ensure the water remains cold.

- Microwave Thawing is the quickest method for small quantities, suitable for immediate cooking.

- Industrial Defrosting Equipment and Meat Defrosting Machines provide a professional solution for large volumes, combining speed with uniform results.

Suitability for Different Types of Food

- Refrigerator Thawing works well for all types of food, especially large cuts of meat and delicate items.

- Cold Water Thawing is effective for smaller, packaged items.

- Microwave Thawing is best for small portions or foods that will be cooked immediately.

- Industrial Defrosting Equipment excels in commercial settings where large quantities of various food types are processed.

Best Practices

When using Industrial Defrosting Equipment or Meat Defrosting Machines, it's crucial to:

- Regularly maintain and service the equipment to ensure it operates at peak efficiency.

- Monitor the thawing process to ensure that food does not enter the temperature danger zone.

- Train staff on the proper use of the equipment to maximize safety and efficiency.

"Choosing the right thawing method depends on multiple factors, including the scale of your operation and the specific foods you're working with," says Chef Antonio Morales, a professional culinary instructor. "In commercial settings, Industrial Defrosting Equipment offers a valuable solution for efficiently managing large volumes, ensuring that food safety and quality are upheld."

Ultimately, understanding the strengths and limitations of each thawing method allows food service professionals to make informed decisions, ensuring that food is prepared safely and efficiently, regardless of the volume or type of food being handled.

Conclusion

Understanding the four approved and safe methods for thawing food—refrigerator thawing, cold water thawing, microwave thawing, and the use of Industrial Defrosting Equipment including Meat Defrosting Machines—is essential for ensuring food safety and quality. Each method has its specific applications, advantages, and considerations, making it crucial for both home cooks and food service professionals to choose the most appropriate technique based on their particular needs.

In commercial settings, where the volume and efficiency of food preparation are paramount, Industrial Defrosting Equipment and Meat Defrosting Machines provide a robust solution for safely thawing large quantities of food. These machines offer speed, uniformity, and safety, ensuring that food retains its quality, flavor, and nutritional value, ready for cooking or further processing.

Whether thawing a small batch of chicken breasts for dinner at home or preparing multiple pounds of meat in a commercial kitchen, selecting the right thawing method is key to maintaining food safety standards and delivering delicious, high-quality meals. As we continue to advance in food technology and equipment, adhering to approved thawing practices remains a cornerstone of food safety, critical to the well-being of consumers everywhere.