Unlock The Secret To Perfect animal pellet making machine: A animal pellet making machine Recipe Guide

Brief Overview of the Importance of Animal Pellet Making in Modern Feed Mills

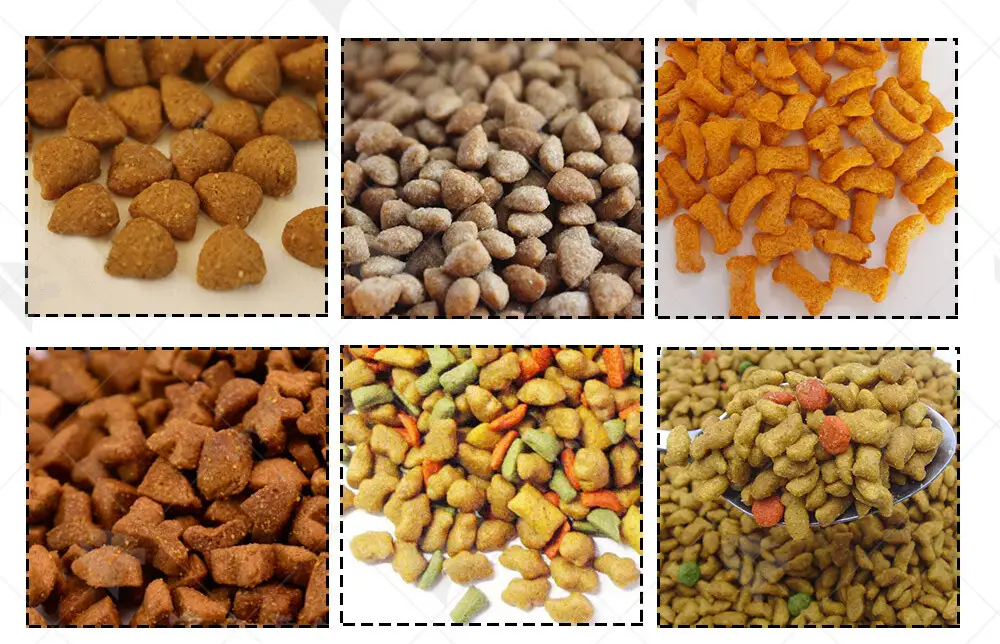

In the ever-evolving landscape of the food and agriculture industry, animal pellet making has emerged as a crucial aspect of modern feed mills. Animal pellets, also known as feed pellets, are a form of processed animal feed that has undergone a series of steps to transform raw ingredients into a uniform, nutrient-dense, and easily digestible form. These pellets play a pivotal role in ensuring the health, growth, and overall well-being of livestock, poultry, and aquatic animals.

The significance of animal pellet making in modern feed mills lies in its ability to optimize feed utilization, reduce waste, and enhance animal performance. By compressing a blend of grains, proteins, vitamins, minerals, and other essential nutrients into a compact pellet, feed mills can provide animals with a balanced and nutritious diet that meets their specific nutritional requirements. This, in turn, leads to improved feed conversion ratios, faster growth rates, and better overall health outcomes for the animals.

Moreover, animal pellet making machines play a vital role in the production process. These machines are designed to automate the entire pellet-making process, from mixing the raw ingredients to extruding and cutting the pellets into their final shape. By automating this process, feed mills can significantly increase production efficiency, reduce labor costs, and minimize the risk of contamination or errors that can occur during manual handling.

In today's environmentally conscious world, eco-friendliness is also a key consideration in the design and operation of animal pellet making machines. Modern, fully automated machines are equipped with advanced features that minimize waste, reduce energy consumption, and promote sustainable production practices. These machines often incorporate dust collection systems, efficient cooling mechanisms, and recyclable materials to minimize their environmental impact.

Understanding the Eco-Friendly Aspect of Animal Pellet Making Machines

In the realm of modern feed mills, the integration of eco-friendly and efficient technologies is paramount for sustainable food production. Among these advancements, the fully automated animal pellet making machine stands out as a game-changer.

Minimizing Waste and Maximizing Efficiency | One of the most notable eco-friendly features of animal pellet making machines lies in their ability to minimize waste and maximize the use of raw materials. These machines employ precision engineering and advanced control systems that ensure accurate mixing and extrusion of feed ingredients. This not only reduces spillage and over-mixing but also ensures that every particle of raw material is utilized efficiently, minimizing waste generation. Moreover, the automated nature of these machines eliminates the need for manual intervention, further reducing the risk of human error and associated waste. By streamlining the production process, animal pellet making machines contribute to a more sustainable and efficient feed mill operation. |

Energy Efficiency and Reduced Carbon Footprint | Another eco-friendly aspect of animal pellet making machines is their energy efficiency. Modern machines are equipped with high-efficiency motors and drive systems that significantly reduce energy consumption during the production process. This not only lowers operating costs for feed mills but also minimizes their carbon footprint, contributing to a greener environment. Furthermore, some advanced models incorporate energy-saving features such as automatic power-down modes when not in use or during low-demand periods. These features ensure that the machines are only consuming energy when necessary, further enhancing their eco-friendliness. |

Sustainable Raw Material Usage | Animal pellet making machines also prioritize the use of sustainable raw materials. Many modern machines are designed to work with a wide range of feed ingredients, including by-products and residues from other industries. By utilizing these materials, feed mills can reduce their reliance on virgin resources and contribute to the circular economy. This approach not only benefits the environment by reducing waste and promoting resource conservation but also provides economic benefits to feed mills by reducing raw material costs. |

Environmentally Responsible Operation and Maintenance | The eco-friendly aspect of animal pellet making machines extends to their operation and maintenance. Modern machines often incorporate features that simplify cleaning and maintenance, reducing the need for harmful chemicals or solvents. This not only ensures the safety of workers but also minimizes the risk of pollution during the maintenance process. Additionally, the durable design and high-quality components of these machines reduce the need for frequent replacements, further minimizing waste and promoting sustainability. |

The Efficiency Advantages of Fully Automated Animal Pellet Making Machines

In the fast-paced world of modern feed mills, efficiency is key to maintaining a competitive edge. Fully automated animal pellet making machines have emerged as a game-changer in this regard, offering a range of efficiency advantages that cannot be overlooked.

1.Streamlined Production Process

One of the most significant efficiency advantages of fully automated animal pellet making machines lies in their ability to streamline the production process. These machines integrate multiple steps, from mixing and extrusion to cutting and drying, into a single, seamless operation. This eliminates the need for manual intervention and reduces the risk of human error, leading to faster and more consistent production rates.

Moreover, the automated nature of these machines allows for precise control over the production process, ensuring that each pellet is of uniform size, shape, and density. This consistency not only improves the quality of the final product but also simplifies downstream processing, such as packaging and storage.

2.Reduced Labor Costs

Another efficiency advantage of fully automated animal pellet making machines is their ability to reduce labor costs. By automating the production process, these machines eliminate the need for a large workforce to manually operate the machinery. This not only saves on labor expenses but also frees up personnel for other tasks, such as quality control and maintenance.

Furthermore, the reduced reliance on manual labor minimizes the risk of workplace injuries and illnesses, leading to a safer and healthier work environment. This, in turn, contributes to higher employee morale and productivity, further enhancing the overall efficiency of the feed mill.

3.Increased Production Capacity

Fully automated animal pellet making machines also offer the advantage of increased production capacity. These machines are designed to operate continuously, with minimal downtime for maintenance or repairs. This allows feed mills to produce larger quantities of pellets in a shorter period, meeting the demands of a growing market.

Moreover, the precision engineering and advanced control systems of these machines ensure that production rates remain consistent, even during peak demand periods. This predictability allows feed mills to better manage their inventory and logistics, further enhancing their operational efficiency.

4.Optimized Resource Utilization

Finally, fully automated animal pellet making machines contribute to efficiency by optimizing the utilization of resources. These machines are designed to minimize waste and maximize the use of raw materials, ensuring that every particle of feed is utilized efficiently. This not only reduces the cost of production but also minimizes the environmental impact of feed mills.

Furthermore, the energy-efficient design of these machines reduces energy consumption during the production process, further enhancing their efficiency. By optimizing the use of resources, fully automated animal pellet making machines contribute to a more sustainable and profitable feed mill operation.

Key Features of a Fully Automated Animal Pellet Making Machine

In the realm of modern feed mills, the fully automated animal pellet making machine stands as a testament to technological advancement and efficiency.

Precision Control System | At the heart of every fully automated animal pellet making machine lies a precision control system. This advanced technology allows for meticulous monitoring and adjustment of every aspect of the production process, from ingredient mixing to extrusion, cutting, and drying. With this level of control, manufacturers can ensure that every pellet produced meets the highest standards of quality and consistency. |

High-Efficiency Extrusion Mechanism | The extrusion mechanism is another crucial feature of a fully automated animal pellet making machine. This mechanism is designed to apply the optimal amount of pressure and heat to the feed mix, transforming it into dense, uniform pellets. The high-efficiency nature of this mechanism ensures that production rates remain high, even during extended operation, making it ideal for large-scale feed mills. |

Automatic Cutting and Sizing | One of the most time-consuming and labor-intensive aspects of traditional pellet production is the cutting and sizing of the pellets. However, fully automated animal pellet making machines eliminate this concern with their built-in automatic cutting and sizing systems. These systems use precise blades and sizing screens to cut the extruded feed into uniformly sized pellets, reducing waste and ensuring that every pellet meets the desired specifications. |

Integrated Drying System | After the pellets are cut and sized, they must be dried to remove excess moisture and ensure proper storage and handling. Fully automated animal pellet making machines incorporate an integrated drying system that efficiently removes moisture from the pellets, often using heat from the extrusion process to minimize energy consumption. This feature not only enhances the quality of the final product but also streamlines the production process. |

User-Friendly Interface | Despite their advanced technology, fully automated animal pellet making machines are designed with user-friendliness in mind. The machines feature intuitive control panels and easy-to-navigate interfaces that allow operators to monitor and adjust production parameters with minimal training. This user-friendly design ensures that even inexperienced personnel can operate the machines efficiently, reducing the need for specialized labor. |

Eco-Friendly Design | Modern fully automated animal pellet making machines are designed with eco-friendliness in mind. Many machines incorporate energy-efficient motors and heating elements, reducing the overall energy consumption of the production process. Additionally, some machines are equipped with recycling systems that minimize waste and maximize the use of raw materials. This eco-friendly design not only benefits the environment but also enhances the profitability of feed mills by reducing operational costs. |

Future Trends and Innovations in Animal Pellet Making Machines

The pursuit of eco-friendliness and efficiency remains at the forefront of these advancements, driving the development of innovative technologies that are transforming the way we produce animal feed.

1.Sustainability and Resource Efficiency

One of the most significant trends in animal pellet making machines is the increasing emphasis on sustainability and resource efficiency. Manufacturers are now designing machines that minimize waste, reduce energy consumption, and utilize renewable materials wherever possible. For example, some advanced machines incorporate closed-loop recycling systems that capture and reuse water and other by-products, reducing the environmental impact of the production process. Additionally, the use of biodegradable materials for machine components and packaging is becoming more common, further enhancing the eco-friendliness of these machines.

2.Advancements in Automation and Connectivity

Another trend that is gaining traction in the animal pellet making machine industry is the increasing level of automation and connectivity. Manufacturers are developing machines that can be seamlessly integrated into smart factory ecosystems, allowing for real-time monitoring and control of production processes. This level of automation not only reduces the need for manual labor but also enhances the precision and efficiency of the production process. Furthermore, the integration of IoT (Internet of Things) technology enables remote monitoring and maintenance, reducing downtime and improving overall operational efficiency.

3.Innovations in Material Processing

Material processing is another area where we are seeing significant advancements in animal pellet making machines. Manufacturers are experimenting with new technologies that can handle a wider range of ingredients, including those with high moisture content or varying particle sizes. This versatility is crucial for modern feed mills, which often need to produce a variety of feed formulations to meet the specific requirements of different animals. Additionally, new extrusion technologies are being developed that can produce pellets with enhanced nutritional profiles, making them more attractive to farmers and animal breeders.

4.Enhanced Health and Safety Features

As the food production industry continues to prioritize health and safety, we are seeing a growing number of animal pellet making machines that incorporate enhanced health and safety features. These machines are designed to minimize the risk of contamination and ensure that the final product meets the highest standards of hygiene. For example, some machines are equipped with advanced cleaning systems that can be easily accessed and thoroughly sanitized, reducing the risk of cross-contamination. Additionally, the use of durable, food-grade materials in machine construction helps to prevent the leaching of harmful chemicals into the feed.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/