Understanding Thecorn snacks manufacturers:The Ultimate Guide Tocorn snacks manufacturers

Importance of Innovation in Staying Competitive within the Corn Snacks Manufacturers Industry

In the highly competitive landscape of the corn snacks manufacturing industry, innovation stands as a cornerstone for sustained growth and market leadership. As consumer preferences evolve rapidly, driven by health-conscious trends, sustainability demands, and the desire for novel flavors and textures, manufacturers must continuously adapt to meet these shifting expectations. Innovation is not merely about introducing new products but also encompasses advancements in production technologies, supply chain efficiency, and packaging solutions.

From a technological perspective, automation and artificial intelligence (AI) are revolutionizing how corn snacks are produced. Automated systems enable manufacturers to achieve higher precision in processing, reducing waste and enhancing product quality. For instance, AI-powered quality control systems can detect defects in real-time, ensuring that only the best snacks reach consumers. Meanwhile, 3D printing technologies are being explored to create unique snack shapes and textures, offering a competitive edge in a crowded market.

Sustainability is another critical area where innovation is reshaping the industry. Consumers increasingly seek eco-friendly products, prompting manufacturers to invest in biodegradable packaging materials and energy-efficient production processes. For example, some companies are adopting renewable energy sources, such as solar or wind power, to reduce their carbon footprint. Additionally, innovations in ingredient sourcing—such as non-GMO corn varieties or locally grown produce—align with consumer values and can differentiate brands in the marketplace.

Flavor innovation remains a key driver of consumer appeal. Manufacturers are leveraging global culinary trends to introduce bold, exotic flavors that cater to diverse palates. Whether it’s spicy chili-lime, umami-rich seaweed, or sweet-and-savory honey-soy combinations, the ability to offer unique taste profiles can significantly boost market share. Moreover, partnerships with food scientists and flavor experts enable companies to stay ahead of trends and anticipate consumer demands before they emerge.

In conclusion, innovation is indispensable for corn snacks manufacturersaiming to thrive in a dynamic global market. By embracing technological advancements, sustainability initiatives, and flavor experimentation, companies can not only meet current consumer expectations but also anticipate future needs, ensuring long-term competitiveness and growth.

Health-Conscious Product Development in the Corn Snacks Manufacturers Industry

The global corn snacks manufacturing sector has undergone a significant transformation in recent years, driven by escalating consumer demand for healthier, more sustainable food options. As awareness around nutrition and ingredient transparency grows, manufacturers are compelled to innovate their product lines to align with these evolving preferences. This shift is not merely a trend but a strategic necessity for brands aiming to remain competitive in a rapidly changing market landscape.

1.Ingredient Sourcing and Innovation

One of the primary drivers of health-conscious product development is the adoption of cleaner ingredient labels. Corn snacks manufacturersare increasingly using non-GMO corn varieties, organic ingredients, and natural flavorings to appeal to health-conscious consumers. For instance, brands like "PureCorn" have eliminated artificial additives, replacing them with plant-based alternatives such as beetroot powder for color or sea salt for seasoning. This focus on natural ingredients not only meets consumer expectations but also aligns with regulatory demands for transparency in labeling.

2.Nutritional Enhancement

Beyond eliminating undesirable additives, manufacturers are actively fortifying corn snacks with essential nutrients. Products enriched with fiber, vitamins, or minerals are gaining traction, particularly in regions where consumers prioritize functional foods. For example, some companies now offer corn chips fortified with iron or probiotics, targeting health-focused demographics such as fitness enthusiasts or parents seeking nutrient-rich snacks for children. This strategy not only broadens the product’s appeal but also allows manufacturers to command premium pricing in health-conscious retail channels.

3.Sustainability as a Core Value

Sustainability is another pillar of health-conscious innovation. Manufacturers are investing in eco-friendly packaging solutions, such as compostable films or recyclable pouches, to reduce environmental impact. Additionally, energy-efficient production processes and waste reduction initiatives are becoming standard practices. For instance, companies like "GreenSnack" have implemented closed-loop systems to recycle corn kernels and minimize water usage, positioning themselves as leaders in sustainable snack manufacturing.

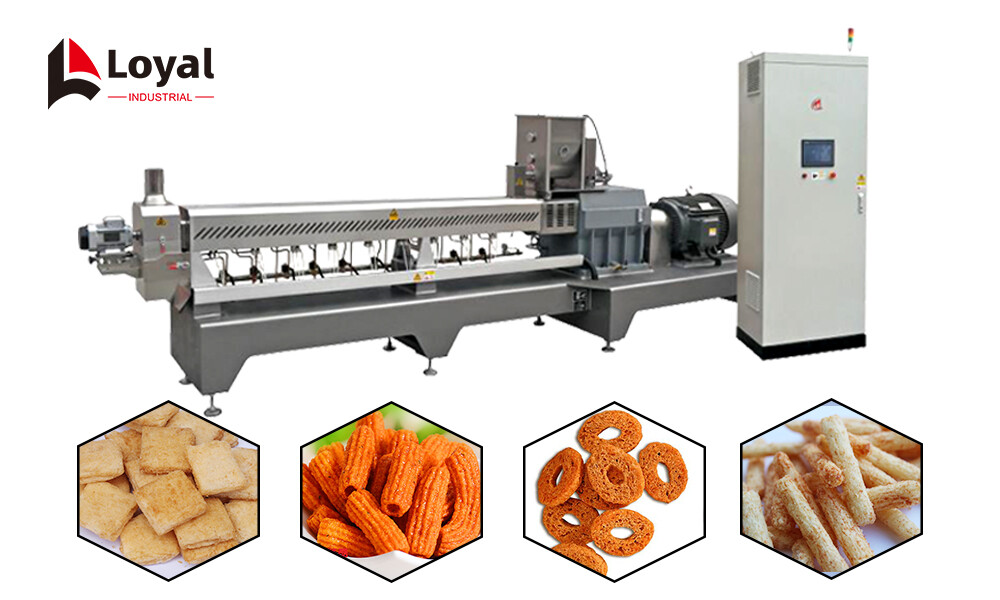

4.Technological Advancements in Food Machinery

To support these innovations, corn snacks manufacturers are leveraging advanced food machinery technologies. Extrusion systems now offer precise control over texture and nutrient retention, while vacuum frying reduces oil content without compromising taste. Automated packaging lines ensure consistent quality and minimize human error, while data analytics tools optimize production efficiency and ingredient usage. These advancements enable manufacturers to scale health-conscious product lines rapidly while maintaining cost-effectiveness.

5.Regulatory and Market Challenges

While health-conscious innovation presents significant opportunities, manufacturers must navigate complex regulatory landscapes. Stringent labeling laws (e.g., EU’s Nutri-Score or FDA guidelines in the U.S.) require transparency in nutritional claims, while consumer advocacy groups demand accountability for sustainability practices. Companies that fail to adapt risk reputational damage or market exclusion.

Sustainability and Eco-Friendly Practices in Corn Snacks Manufacturing

The snack food industry is facing increasing pressure to adopt sustainable practices, and corn snacks manufacturers are at the forefront of this green revolution. As environmental concerns grow among consumers, manufacturers are implementing innovative solutions throughout their production processes to reduce ecological impact while maintaining product quality.

1.Energy-Efficient Production Methods

Modern corn snacks manufacturers are investing in advanced technologies to minimize energy consumption:

• High-efficiency extruders that reduce power usage by up to 25% compared to conventional models

• Heat recovery systems that capture and reuse thermal energy from ovens and fryers

• Solar-powered production facilities in sun-rich regions

• Smart sensors and IoT-enabled equipment that optimize energy use in real-time

These innovations not only lower carbon footprints but also result in significant cost savings over time, proving that sustainability and profitability can go hand-in-hand.

2.Waste Reduction Strategies

Leading manufacturers are implementing comprehensive waste management programs:

• Byproduct utilization: Corn husks and other processing residues converted into animal feed or biofuel

• Closed-loop water systems that recycle processing water

• Precision dosing systems that minimize ingredient waste

• Advanced sorting equipment that reduces product loss during quality control

3.Sustainable Packaging Innovations

Packaging represents one of the biggest environmental challenges, and corn snacks manufacturers are responding with:

• Compostable bags made from plant-based materials

• Monolayer films that maintain shelf life while being easier to recycle

• Edible packaging prototypes for certain product types

• Minimalist designs that use less material without compromising protection

4.Sustainable Sourcing Practices

• Partnerships with local farmers practicing regenerative agriculture

• Rainforest Alliance certified corn sourcing programs

• Blockchain technology for transparent supply chain tracking

• Water conservation initiatives in agricultural partnerships

5.The Business Case for Sustainability

While implementing these practices requires upfront investment, corn snacks manufacturers are seeing tangible benefits:

• 72% of consumers willing to pay premium for sustainable snacks (Nielsen)

• Improved brand reputation and customer loyalty

• Compliance with increasingly strict environmental regulations

• Long-term cost savings through efficiency gains

6.Challenges in Implementation

• Higher initial costs for green technologies

• Technical limitations of some sustainable materials

• Need for employee training on new processes

• Balancing sustainability with product shelf life requirements

Technological Advancements in Production

The global corn snacks manufacturers sector has witnessed transformative technological breakthroughs that have redefined production efficiency, product quality, and sustainability. These advancements are not merely incremental improvements but rather paradigm shifts that enable manufacturers to stay competitive in a rapidly evolving market.

1.Precision Engineering in Extrusion and Shaping

Modern extrusion technology stands at the forefront of corn snack innovation. Advanced twin-screw extruders, equipped with real-time monitoring systems, allow corn snacks manufacturers to achieve unprecedented control over texture, porosity, and flavor retention. For instance, technologies like vacuum extrusion minimize oil absorption during frying, creating healthier snack options without compromising on crunchiness. Meanwhile, 3D printing-inspired shaping techniques enable the creation of intricate snack geometries, catering to consumer preferences for novelty and variety.

2.Automation and Robotics in Manufacturing

Automation has revolutionized corn snack production lines, reducing labor costs and human error while boosting output. Robotic arms, guided by AI-powered vision systems, now handle tasks such as packaging, quality inspection, and even ingredient dosing. For example, collaborative robots (cobots) can work alongside human operators to enhance flexibility in small-batch production, a trend increasingly favored by corn snacks manufacturers targeting niche markets.

3.Sustainability-Driven Innovations

As environmental consciousness grows, corn snacks manufacturers are adopting technologies that reduce waste and energy consumption. Biorefineries integrated into production plants convert corn by-products into biofuels or animal feed, closing the loop on resource utilization. Additionally, water-efficient cooling systems and energy-recycling heat exchangers help minimize operational footprints. Innovations like edible packaging derived from cornstarch further align the industry with eco-friendly goals.

4.Data Analytics and Predictive Maintenance

The integration of IoT devices and data analytics platforms empowers corn snacks manufacturers to optimize production in real time. Sensors embedded in machinery monitor vibrations, temperatures, and wear patterns, enabling predictive maintenance that prevents costly breakdowns. Meanwhile, big data analytics analyze consumer trends, supply chain disruptions, and ingredient costs, guiding strategic decisions to maximize profitability.

Flavor Innovation and Cultural Fusion

In the highly competitive landscape of corn snacks manufacturers, flavor innovation and cultural fusion have emerged as critical drivers of market expansion. As consumer preferences evolve toward more diverse and adventurous taste profiles, manufacturers are leveraging advanced food technology and cross-cultural insights to redefine product offerings.

1.Global Flavor Trends and Consumer Demand

Corn snacks manufacturers are increasingly prioritizing flavor innovation to cater to regional palates. For instance, Latin American markets favor bold, spicy flavors such as ají amarillo (Peruvian yellow chili) and chipotle, while Asian consumers gravitate toward umami-rich profiles like shichimi togarashi (Japanese seven-spice blend) or gochujang (Korean chili paste). By incorporating these flavors into their production lines, manufacturers can tap into emerging markets and strengthen brand loyalty.

2.Technological Advancements in Flavor Integration

Modern food engineering techniques enable corn snacks manufacturers to achieve precise flavor delivery. Encapsulation technologies, such as microencapsulation, protect heat-sensitive ingredients (e.g., herbs, spices) during extrusion, ensuring consistent taste profiles. Additionally, supercritical fluid extraction (SFE) allows for the isolation of natural flavor compounds without chemical solvents, aligning with clean-label trends. This integration of technology not only enhances product quality but also reduces waste and production costs.

3.Cultural Fusion as a Competitive Edge

Cross-cultural flavor combinations are reshaping the snack aisle. Corn snacks manufacturers are experimenting with hybrid cuisines, such as "Mediterranean-inspired" za’atar-infused corn puffs or "Indian-Mexican fusion" masala-chili corn chips. These innovations appeal to millennials and Gen Z consumers, who seek authentic yet globally influenced snacking experiences. Collaborations with local chefs and food influencers further amplify cultural authenticity, driving product differentiation.

4.Health-Conscious Flavor Development

As demand for healthier snacks grows, corn snacks manufacturers are reformulating flavors to reduce sodium, sugar, and artificial additives. Natural sweeteners (e.g., monk fruit, stevia) and savory seasonings (e.g., turmeric, garlic powder) offer alternatives that align with wellness trends. Moreover, "functional flavors"—such as probiotic-infused corn snacks with a yogurt coating—tap into the intersection of taste and nutrition, positioning manufacturers as leaders in the health-conscious snack segment.

5.Technological Integration in Flavor Development

Corn snacks manufacturers are adopting cutting-edge food engineering techniques to achieve precise flavor profiles. For instance, encapsulation technologies, such as spray drying and fluidized bed coating, allow manufacturers to protect heat-sensitive ingredients (e.g., spices, herbs) during extrusion, ensuring consistent taste retention. Additionally, supercritical fluid extraction (SFE) and molecular gastronomy methods enable the isolation and recombination of natural flavor compounds, reducing reliance on artificial additives. This technological synergy not only enhances product quality but also aligns with clean-label trends, a critical factor in consumer decision-making.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/