The Ultimate Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food Guide to 2024

Introduction to Panko Bread Crumb Pulverizers

The Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food industry has seen significant advancements in recent years. These machines are essential for producing high-quality panko bread crumbs, which are a staple in creating crispy fried food. The pulverizer grinder machines are designed to efficiently crush and grind bread into fine, consistent crumbs, ensuring the ideal texture for a variety of culinary applications.

Panko bread crumbs, known for their light and airy texture, are crucial in achieving the perfect crispy coating for fried foods. The Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food ensures that the bread crumbs are uniform in size and texture, which is vital for consistent frying results. These machines cater to both small-scale artisanal producers and large industrial food manufacturers, highlighting their versatility and importance in the food processing sector.

The development of Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food technology has focused on improving efficiency, consistency, and ease of use. Modern machines are equipped with advanced features that allow for precise control over the grinding process, ensuring that the panko crumbs meet specific quality standards. This precision is particularly important for maintaining the delicate texture that panko is known for.

In the competitive world of food production, having reliable and efficient equipment like the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food is essential. These machines not only streamline the production process but also help maintain the high quality that consumers expect from their crispy fried foods.

How Pulverizer Grinders Work

Understanding the mechanics of the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food is essential for appreciating its role in food processing. These machines operate by using a combination of crushing and grinding mechanisms to break down bread into fine crumbs. The process begins with feeding bread into the machine, where it is initially crushed by rotating blades.

The crushed bread is then passed through a series of grinding plates that further reduce the size of the crumbs. This multi-stage process ensures that the final product is finely ground and uniform in texture. The Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food uses adjustable settings to control the fineness of the crumbs, allowing producers to customize the end product according to their specific needs.

One of the key features of the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food is its ability to maintain the integrity of the panko texture. Unlike traditional bread crumbs, panko crumbs are larger and have a flaky consistency, which is crucial for achieving a crispy coating on fried foods. The machine's design takes this into account, ensuring that the grinding process does not compromise the quality of the panko crumbs.

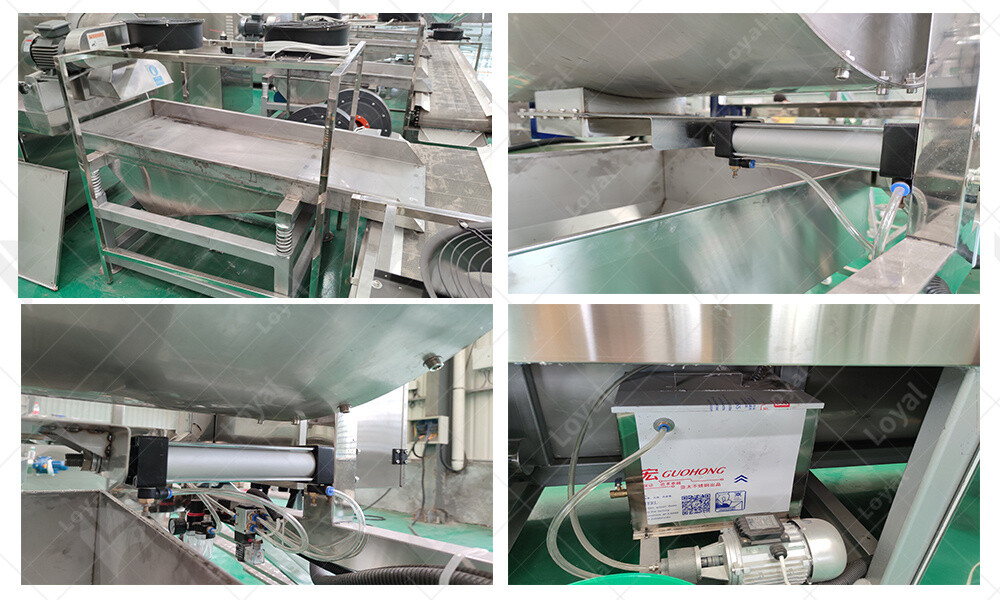

Moreover, modern Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food models are built with efficiency and hygiene in mind. They are constructed from food-grade materials that are easy to clean and maintain, reducing the risk of contamination. This is particularly important in large-scale food production environments, where maintaining high standards of cleanliness is paramount.

Key Features of Pulverizer Machines

Pulverizer machines, such as the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food, are integral to the food processing industry, offering a range of advanced features that ensure efficient and consistent production. One of the key features is its high-capacity grinding capability, enabling the machine to process large volumes of panko bread crumbs quickly and efficiently. This ensures a steady supply of finely ground crumbs for crispy fried food applications.

Another significant feature is the adjustable grind settings. The Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food allows operators to fine-tune the grind size, producing crumbs of varying textures to meet specific culinary requirements. This flexibility is crucial for manufacturers aiming to cater to diverse market demands.

Durability and ease of maintenance are also standout features of these machines. Constructed from high-quality materials, the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food is designed to withstand the rigors of continuous operation in industrial settings. Moreover, its modular design facilitates easy cleaning and component replacement, minimizing downtime and ensuring long-term operational efficiency.

Lastly, the integration of advanced safety mechanisms is a critical feature. The Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food is equipped with sensors and automatic shut-off functions to prevent accidents and ensure safe operation. These safety features protect both the machinery and the operators, enhancing overall workplace safety.

Benefits of Using Pulverizers in Food Processing

The use of pulverizer machines, specifically the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food, offers numerous benefits in food processing, making them an invaluable asset for manufacturers. One primary benefit is the consistency in product quality. By using a pulverizer, manufacturers can achieve uniform particle sizes, which is essential for producing high-quality crispy fried foods. This consistency translates to better texture and appearance, meeting consumer expectations.

Another significant benefit is the increase in production efficiency. The Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food processes large quantities of bread crumbs swiftly, reducing the time and labor required compared to manual grinding methods. This efficiency allows manufacturers to scale up production and meet high market demands without compromising on quality.

Cost savings are also a notable advantage. By streamlining the grinding process, the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food reduces waste and optimizes the use of raw materials. Additionally, the durability and low maintenance requirements of the machine lead to lower operational costs over time, providing a favorable return on investment.

Finally, the versatility of pulverizer machines enhances their value in food processing. The ability to produce different crumb sizes and textures enables manufacturers to diversify their product offerings. Whether for coating meats, vegetables, or other food items, the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food can be adjusted to produce the ideal crumb for various applications, thereby expanding the range of crispy fried foods available to consumers.

Maintenance Tips for Pulverizer Grinders

Maintaining a Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food is crucial for ensuring longevity and optimal performance. Regular maintenance helps prevent breakdowns and ensures consistent production quality. Here are some essential maintenance tips:

Firstly, it is important to schedule routine inspections. Regularly check for wear and tear on critical components such as blades, belts, and bearings. Replacing worn-out parts before they fail can prevent major disruptions. For instance, the blades of a Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food should be inspected for sharpness and alignment, as dull or misaligned blades can affect the texture and consistency of the final product.

Secondly, lubrication is key to the smooth operation of any pulverizer grinder. Ensure that all moving parts are adequately lubricated according to the manufacturer's guidelines. Over-lubrication can attract dust and breadcrumbs, leading to clogs, while under-lubrication can cause excessive wear. Proper lubrication ensures that the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food operates efficiently and quietly.

Thirdly, maintaining cleanliness is vital. After each production run, thoroughly clean the machine to remove any breadcrumb residues. Accumulated crumbs can cause blockages and affect the machine’s efficiency. Use appropriate cleaning agents that do not corrode the machine parts. Regular cleaning of a Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food helps maintain hygiene standards and prevents contamination.

Lastly, keep detailed maintenance records. Documenting all inspections, part replacements, and servicing activities helps track the machine’s condition and predict when future maintenance will be needed. This proactive approach ensures the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food remains in top working condition, minimizing downtime and maximizing productivity.

Safety Considerations for Pulverizer Machines

Ensuring the safety of operators and maintaining safe working conditions are paramount when using a Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food. Implementing robust safety measures helps prevent accidents and injuries. Here are some critical safety considerations:

First and foremost, operators should be adequately trained. Comprehensive training programs should cover the operation, maintenance, and emergency procedures for the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food. Trained operators are more likely to handle the machine correctly and identify potential safety issues before they become serious problems.

Secondly, the machine should be equipped with proper safety guards and emergency stop mechanisms. Safety guards protect operators from moving parts, while emergency stop buttons allow for immediate shutdown in case of an emergency. Regularly test these safety features to ensure they are functioning correctly. These mechanisms are essential for preventing accidents and ensuring quick responses to potential hazards.

Thirdly, establish a strict protocol for machine operation. This includes wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and ear protection. Operators should also avoid loose clothing and jewelry that could get caught in the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food. Clear operational guidelines help maintain a safe working environment.

Lastly, regular safety audits are crucial. Conducting periodic safety inspections helps identify and rectify potential hazards. Ensure that the working area around the Panko Bread Crumb Pulverizer Grinder Machine Crispy Fried Food is clean and free of obstructions. Implementing a safety checklist can help systematically address all safety aspects and ensure compliance with industry standards.

Comparing Pulverizer Grinders to Traditional Methods

Feature/Method | Panko Bread Crumb Pulverizer Grinder Machine | Traditional Bread Crumb Grinding Methods |

Efficiency | High efficiency, capable of processing large volumes quickly | Lower efficiency, time-consuming, labor-intensive |

Consistency | Provides uniform crumb size and texture | Inconsistent crumb size and texture |

Versatility | Adjustable settings for different crumb textures | Limited to specific types of crumbs |

Automation | Fully automated, reduces need for manual intervention | Requires significant manual effort |

Quality Control | High precision in controlling output quality | Variable quality control |

Maintenance | Modern machines designed for easy maintenance | Higher maintenance due to older technology |

Cost Efficiency | Reduces long-term operational costs through automation | Higher operational costs due to labor and time |

Sustainability | Energy-efficient designs available | Typically less energy-efficient |

The Panko Bread Crumb Pulverizer Grinder Machine clearly outperforms traditional bread crumb grinding methods in terms of efficiency, consistency, and overall quality. Its advanced features enable food manufacturers to produce high-quality, uniform bread crumbs ideal for crispy fried food applications.

Innovations in Pulverizer Grinder Technology

The Panko Bread Crumb Pulverizer Grinder Machine has undergone significant technological advancements, shaping the future of bread crumb production for crispy fried food. One major innovation is the integration of smart sensors and automation systems. These sensors monitor various parameters in real-time, such as temperature, humidity, and particle size, ensuring optimal grinding conditions and consistent product quality.

Another key development is the enhancement of energy efficiency. Modern Panko Bread Crumb Pulverizer Grinder Machines are designed with advanced energy-saving technologies, reducing power consumption and minimizing the environmental footprint. This aligns with the growing trend towards sustainability in the food processing industry.

Moreover, the use of high-grade materials and cutting-edge engineering has improved the durability and longevity of these machines. Innovations in wear-resistant coatings and precision components mean that the Panko Bread Crumb Pulverizer Grinder Machine can operate under high-stress conditions with minimal maintenance, ensuring continuous production and reducing downtime.

Finally, the incorporation of modular designs allows for greater flexibility and scalability. Food manufacturers can easily upgrade or modify their Panko Bread Crumb Pulverizer Grinder Machines to meet changing production demands. This adaptability is crucial in a dynamic market where consumer preferences for crispy fried food continuously evolve.

These innovations highlight the Panko Bread Crumb Pulverizer Grinder Machine as a cornerstone in modern food processing technology, offering enhanced performance, sustainability, and versatility to meet the needs of the 2024 food industry landscape.

Troubleshooting Common Pulverizer Grinder Issues

Q1: Why is my Panko Bread Crumb Pulverizer Grinder Machine not producing uniform crumbs?

A1: Uneven crumb production in a Panko Bread Crumb Pulverizer Grinder Machine can be caused by several factors. First, check the sharpness and alignment of the grinding blades. Dull or misaligned blades can lead to inconsistent crumb sizes.

Q2: What should I do if my Panko Bread Crumb Pulverizer Grinder Machine overheats during operation?

A2: Overheating in a Panko Bread Crumb Pulverizer Grinder Machine can result from several issues. Start by checking the ventilation and cooling systems; ensure they are clean and functioning correctly to dissipate heat. Additionally, overloading the machine can cause it to overheat, so make sure to operate within the recommended capacity.

Q3: How can I resolve frequent blockages in my Panko Bread Crumb Pulverizer Grinder Machine?

A3: Frequent blockages in a Panko Bread Crumb Pulverizer Grinder Machine can disrupt production and reduce efficiency. To address this, first, ensure that the bread crumbs being fed into the machine are free from large chunks and foreign objects that could cause blockages. Regularly clean the feed chute and grinding chamber to prevent buildup of residual material.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com