The Ultimate Guide Totwin-screw extruder instant baby cereal powder food machine Updated 2024

Highlighting the key benefits and advantages of this technology

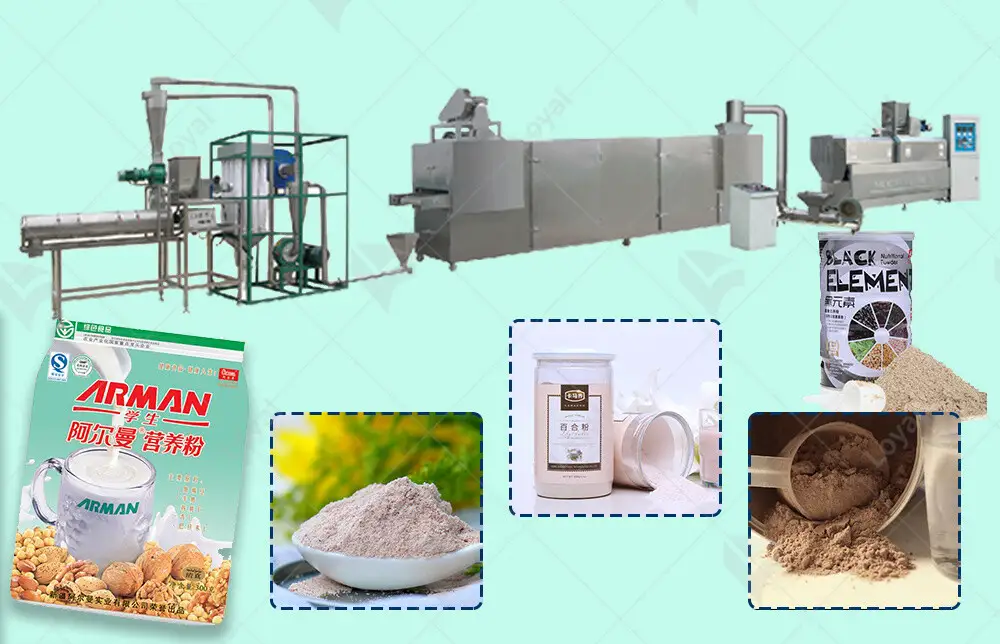

In the realm of baby food production, innovation is key to meeting the evolving demands of consumers and staying ahead in a competitive market. One such innovation that has revolutionized the industry is the advanced fully automated twin-screw extruder for instant baby cereal powder. This cutting-edge technology offers numerous benefits and advantages that make it an indispensable tool for manufacturers looking to enhance their production processes and product quality.

Firstly, the twin-screw extruder technology is renowned for its ability to produce cereal powder with unparalleled consistency and quality. The precise control over temperature, pressure, and shear rates within the extruder allows for the creation of a uniform, fine-textured powder that is ideal for baby food applications. This level of quality assurance is essential in the baby food industry, where even the slightest variations in product consistency can have significant implications for infant health and safety.

Another significant advantage of the twin-screw extruder is its increased production efficiency and capacity. By automating the entire extrusion process, manufacturers can significantly reduce the labor requirements and the potential for human error. This, in turn, leads to faster production cycles and higher output volumes, allowing manufacturers to meet the growing demand for baby food products.

Moreover, the twin-screw extruder is designed with energy efficiency in mind. By optimizing the flow of material through the extruder and minimizing waste, manufacturers can significantly reduce their energy consumption and operating costs. This not only benefits the manufacturer's bottom line but also aligns with the growing consumer preference for sustainable and environmentally friendly products.

Furthermore, the fully automated aspect of the twin-screw extruder provides manufacturers with unprecedented control over their production processes. With remote monitoring and control capabilities, manufacturers can keep track of their production lines in real-time, ensuring that everything is running smoothly and efficiently. This level of visibility and control is crucial for maintaining high-quality standards and ensuring that products meet all relevant safety and regulatory requirements.

In conclusion, the advanced fully automated twin-screw extruder for instant baby cereal powder represents a significant leap forward in baby food production technology. Its ability to produce high-quality, consistent products with increased efficiency and reduced energy consumption makes it an invaluable tool for manufacturers looking to stay ahead in a rapidly evolving market. As the demand for healthy, convenient, and nutritious baby food continues to grow, the twin-screw extruder will play an increasingly important role in shaping the future of the industry.

Understanding the Twin-Screw Extruder Technology

In the world of industrial food machinery, the twin-screw extruder stands as a testament to technological advancement and innovation. This advanced, fully automated machine has revolutionized the production of instant baby cereal powder, transforming an intricate process into a seamless, efficient, and highly controlled operation. As an industrial food machinery expert, I am excited to delve deeper into the intricacies of this remarkable technology and its unparalleled contributions to the baby food industry.

1.Twin-Screw Design

At the core of the twin-screw extruder lies its innovative design, featuring two parallel, intermeshing screws that rotate within a heated barrel. This unique configuration allows for a complex series of operations to take place simultaneously, including mixing, kneading, shearing, and extrusion. The intermeshing action of the screws ensures intimate contact between the ingredients, leading to a uniform and homogeneous mixture that is crucial for the production of high-quality instant baby cereal powder.

2.Versatility in Processing

One of the most remarkable aspects of the twin-screw extruder is its versatility. Unlike traditional food processing methods, this machine can handle a diverse range of raw materials, from grains and flours to fruits, vegetables, and even nutritional additives. The precision control over temperature, pressure, and screw speed enables manufacturers to tailor the extrusion process to the specific requirements of their product, resulting in a customized instant baby cereal powder that meets the highest standards of nutrition and taste.

3.Nutrient Retention and Product Quality

The twin-screw extruder's gentle handling of ingredients and precise control over processing conditions make it ideal for preserving the nutritional integrity of the raw materials. During the extrusion process, the gentle shear forces and controlled temperatures minimize the degradation of vitamins, minerals, and other essential nutrients. This, in turn, leads to a final product that is not only delicious but also rich in the nutrients that babies need for healthy growth and development.

4.Automation and Efficiency

Fully automated, the twin-screw extruder streamlines the production process, reducing labor costs and minimizing the risk of contamination or human error. The integration of advanced sensors, control systems, and monitoring technologies ensures that every aspect of the extrusion process is tightly regulated and optimized for maximum efficiency. This not only results in a faster turnaround time but also ensures consistent product quality from batch to batch.

5.Customization and Innovation

The twin-screw extruder's versatility extends beyond the processing of raw materials. With the ability to adjust process parameters such as screw speed, temperature profile, and die configuration, manufacturers can easily customize the final product to meet specific dietary requirements or market trends. Whether it's gluten-free, organic, or fortified with additional vitamins and minerals, the twin-screw extruder can produce an instant baby cereal powder that perfectly aligns with consumer demands.

The Advantages of Using a Twin-Screw Extruder for Instant Baby Cereal Powder

In the dynamic landscape of baby food production, the adoption of advanced technologies has become paramount for ensuring the safety, nutrition, and convenience of infant meals. Among these technologies, the fully automated twin-screw extruder stands out as a game-changer for the production of instant baby cereal powder. As an industrial food machinery expert, I will elaborate on the numerous advantages that this machine brings to the table, transforming the way baby cereal powder is manufactured.

Enhanced Nutrient Retention | One of the most significant advantages of using a twin-screw extruder for instant baby cereal powder lies in its ability to retain nutrients. During the extrusion process, the gentle mixing and kneading actions of the intermeshing screws minimize heat exposure and shear stress on the ingredients. This results in a final product that retains a higher percentage of essential vitamins, minerals, and other nutrients compared to traditional processing methods. This is particularly important for baby food, where every nutrient counts in supporting healthy growth and development. |

Uniformity and Consistency | The twin-screw extruder's precision control over temperature, pressure, and screw speed ensures a highly uniform and consistent final product. This level of control is crucial for ensuring that every batch of instant baby cereal powder meets strict quality standards. With uniform particle size, texture, and nutrient distribution, manufacturers can guarantee that every spoonful of cereal powder provides the same nutritional benefits to babies. |

Increased Efficiency and Reduced Waste | Fully automated, the twin-screw extruder streamlines the production process, significantly reducing labor costs and minimizing waste. The machine's ability to process a wide range of ingredients with minimal pre-treatment requirements translates into higher production yields and lower material loss. Furthermore, the elimination of manual steps and the integration of advanced sensors and control systems minimize the risk of errors and contamination, further enhancing overall efficiency and product quality. |

Customizable Formulas | Another advantage of the twin-screw extruder is its flexibility in terms of product formulation. Manufacturers can easily adjust process parameters such as screw speed, temperature profile, and die configuration to produce instant baby cereal powder with tailored nutritional profiles. This allows for the creation of specialized formulas for different age groups, dietary requirements, or even specific health conditions. The ability to customize products in response to market demands and consumer preferences is a key factor in staying competitive in the baby food industry. |

Scalability and Future-Proofing | The twin-screw extruder's modular design and scalability make it an ideal investment for manufacturers looking to expand their production capacity or diversify their product offerings. As baby food trends evolve and consumer preferences shift, the extruder's versatility ensures that manufacturers can quickly adapt their production processes to meet new demands. Additionally, the machine's integration with the latest automation and control technologies ensures that it remains future-proof, capable of incorporating advancements in food processing technology as they emerge. |

The Fully Automated Aspect of the Machine

In the pursuit of excellence in baby food production, the fully automated twin-screw extruder emerges as a cornerstone technology that revolutionizes the manufacturing process of instant cereal powder. As an industrial food machinery expert, I am delighted to delve into the intricacies of this machine's automation capabilities, highlighting how they streamline every aspect of production, from ingredient preparation to final packaging.

1.Seamless Integration with Upstream and Downstream Processes

At the heart of the fully automated twin-screw extruder's design lies its seamless integration with upstream and downstream processes. The machine is equipped with advanced sensors and control systems that enable it to communicate with other equipment in the production line, ensuring a smooth flow of materials and information. This integration minimizes manual intervention and eliminates the potential for errors, significantly enhancing production efficiency and product quality.

2.Automated Ingredient Handling and Feeding

One of the key features of the fully automated twin-screw extruder is its ability to handle and feed ingredients with precision. The machine incorporates automated feeding systems that accurately meter and convey ingredients to the extruder's hopper. This eliminates the need for manual weighing and mixing, reducing labor costs and minimizing the risk of contamination. Additionally, the machine's intelligent control system adjusts feeding rates based on real-time process parameters, ensuring optimal ingredient ratios and consistent product quality.

3.Automated Process Control and Monitoring

The fully automated twin-screw extruder is equipped with a comprehensive suite of sensors and control systems that monitor and adjust process parameters in real-time. These systems continuously monitor factors such as temperature, pressure, screw speed, and material flow, enabling the machine to automatically adjust its operation to maintain optimal processing conditions. This level of automation ensures that the extrusion process is precisely controlled, resulting in a consistently high-quality instant baby cereal powder.

4.Automated Cleaning and Maintenance

Another significant advantage of the fully automated twin-screw extruder is its ability to facilitate automated cleaning and maintenance procedures. The machine is designed with quick-release components and easy-to-access areas, allowing for efficient cleaning after each production run. Additionally, the machine's control system can initiate automated cleaning cycles using specialized cleaning agents, further reducing downtime and ensuring that the extruder remains in optimal working condition.

5.Intelligent Data Collection and Analysis

The fully automated twin-screw extruder is also equipped with intelligent data collection and analysis capabilities. The machine's control system records and stores process data, enabling manufacturers to track production performance over time and identify areas for improvement. This data can also be used to optimize process parameters, further enhancing product quality and production efficiency. The ability to analyze and leverage this data is crucial for manufacturers looking to stay ahead in the competitive baby food market.

The Impact on Baby Food Production

The introduction of the advanced fully automated twin-screw extruder for instant baby cereal powder has marked a paradigm shift in baby food production. As an industrial food machinery expert, I am excited to explore the profound impact this innovative technology has had on the industry, transforming the way we produce nutritious and convenient baby food.

Enhanced Production Efficiency | One of the most immediate and significant impacts of the twin-screw extruder is its ability to enhance production efficiency. By automating critical processes such as ingredient handling, mixing, extrusion, and even cleaning, manufacturers can significantly reduce downtime and increase throughput. This results in faster production cycles and a higher volume of output, allowing companies to meet growing market demands more efficiently. |

Improved Product Quality and Consistency | The fully automated twin-screw extruder also contributes to improved product quality and consistency. By precisely controlling process parameters such as temperature, pressure, and screw speed, the machine ensures that each batch of instant baby cereal powder is produced to the highest standards. This level of precision eliminates variability in product quality, ensuring that every jar or packet of baby cereal contains the same nutritious and delicious formula. |

Reduced Labor Costs and Enhanced Safety | Another key impact of the twin-screw extruder is its ability to reduce labor costs and enhance workplace safety. By automating labor-intensive tasks, the machine eliminates the need for a large workforce, reducing labor expenses and freeing up personnel for other value-added activities. Additionally, the machine's enclosed design and automated cleaning processes minimize exposure to potential hazards, creating a safer working environment for employees. |

Increased Flexibility and Customization | The advanced fully automated twin-screw extruder also offers manufacturers increased flexibility and customization options. With its modular design and interchangeable screw configurations, the machine can be adapted to produce a wide range of instant baby cereal powder formulations, catering to different nutritional requirements and consumer preferences. This flexibility enables manufacturers to stay ahead of market trends and respond quickly to changing consumer demands. |

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/