The Ultimate Guide Toanimal pellet feed machine Updated 2024

Expanding on the Benefits of High-Efficiency Fully Automated Animal Pellet Feed Machines

Beyond the immediate advantages of producing palatable and nutritious pelleted feed, high-efficiency fully automated animal pellet feed machines offer a multitude of benefits that modern farmers cannot afford to ignore. These machines are designed to streamline the entire feed production process, from ingredient mixing to final product packaging, resulting in significant improvements in efficiency, cost savings, and environmental sustainability.

Efficiency Enhancements | One of the most notable benefits of automated animal pellet feed machines is their ability to significantly increase production efficiency. By automating tasks such as ingredient weighing, mixing, and extrusion, these machines eliminate the need for manual labor, reducing the risk of human error and speeding up the overall production process. This not only saves time but also allows farmers to produce larger quantities of feed in a shorter period, enabling them to meet the demands of their growing livestock herds. |

Cost Savings | Another key advantage of automated animal pellet feed machines is their cost-effectiveness. While the initial investment in these machines may seem substantial, the long-term savings in labor costs, reduced waste, and increased production efficiency more than justify the expense. By automating the feed production process, farmers can reduce their reliance on manual labor, which can be expensive and prone to errors. Additionally, automated machines are designed to minimize waste by precisely controlling ingredient ratios and ensuring consistent product quality, further reducing costs associated with overproduction or scrap. |

Environmental Sustainability | In today's world, environmental sustainability is a top priority for farmers and consumers alike. High-efficiency fully automated animal pellet feed machines contribute to this goal by reducing waste and conserving resources. By precisely controlling ingredient ratios and minimizing production errors, these machines help to reduce the amount of excess feed that ends up in landfills or waterways. Furthermore, the use of automated machines can lead to more efficient use of energy and water resources, further reducing the environmental footprint of animal feed production. |

Consistency and Quality Control | Another significant benefit of automated animal pellet feed machines is their ability to ensure product consistency and quality control. By automating the production process, these machines eliminate the variability that can occur with manual production methods. This results in a more uniform and predictable product, which is essential for maintaining the health and productivity of livestock. Additionally, automated machines are equipped with advanced monitoring and control systems that allow farmers to closely monitor the production process and make adjustments as needed to ensure the highest possible product quality. |

Understanding Animal Pellet Feed Machines

In the realm of modern agriculture, the quest for increased efficiency and reduced labor costs has led to the widespread adoption of advanced machinery. Among these technological marvels, the high-efficiency fully automated animal pellet feed machine stands as a testament to innovation and practicality. This sophisticated piece of equipment revolutionizes the way animal feed is processed and distributed, ensuring optimal nutrition for livestock while streamlining farm operations.

What is an Animal Pellet Feed Machine?

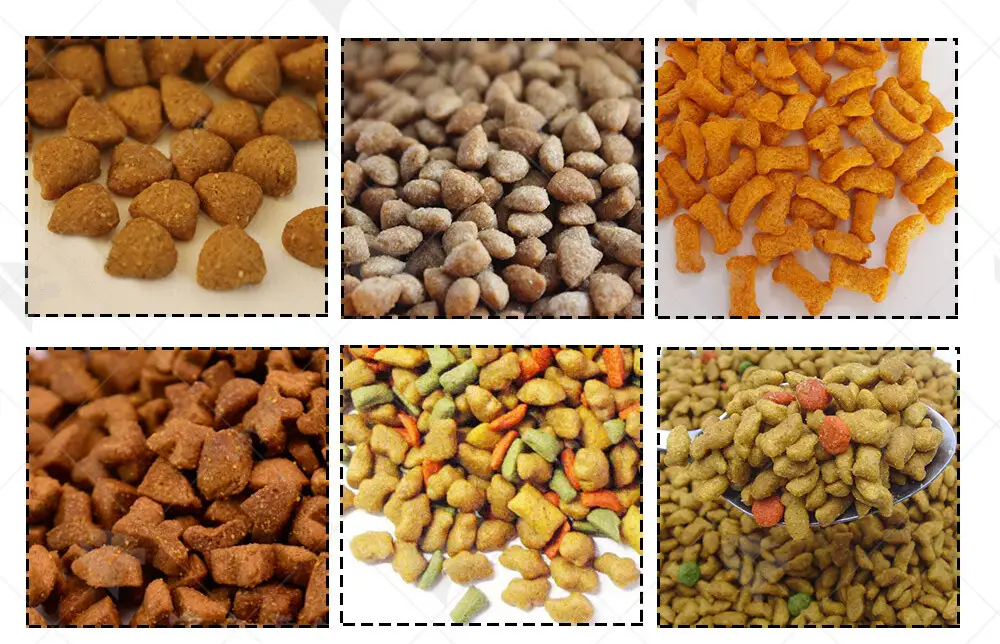

An animal pellet feed machine, at its core, is a specialized industrial food machinery designed to transform raw ingredients into compact, uniform pellets that are highly palatable and nutritious for animals. These machines integrate various processes, including grinding, mixing, extruding, and cutting, to create pellets tailored to the specific dietary needs of various livestock species such as cattle, pigs, poultry, and even aquatic animals.

The Importance of Pellet Feed

Pelletizing feed offers several advantages over traditional feed forms like meal or mash. Firstly, pellets have a higher density, allowing for more efficient storage and transportation. They also resist separation during handling, ensuring a consistent mix of nutrients throughout the feed. Moreover, the extrusion process used in pellet feed production enhances the bioavailability of nutrients, making them more easily digestible for animals. As a result, animals fed with pellets tend to exhibit improved growth rates, better health, and reduced feed waste.

Key Components of an Animal Pellet Feed Machine

A high-efficiency fully automated animal pellet feed machine comprises several essential components that work in harmony to achieve its objectives:

Feeding System | This component is responsible for delivering the raw materials, such as grains, cereals, protein sources, minerals, and vitamins, into the machine at a controlled rate. |

Grinding and Mixing Unit | The raw ingredients are then subjected to grinding to achieve a uniform particle size, followed by mixing to ensure an even distribution of all components. This step is crucial for creating a balanced feed formula. |

Conditioning Chamber | Here, steam or water is added to the mix to increase its moisture content and temperature, facilitating the pelletizing process. Conditioning improves the plasticity of the material, making it easier to form into pellets. |

Extruder and Die | The conditioned mix is then forced through a die with tiny holes under high pressure, forming cylindrical pellets. The extruder plays a pivotal role in shaping and compressing the material into the desired pellet form. |

Cutter and Pellet Cooler | Immediately after extrusion, the pellets are cut to the desired length and passed through a cooler to reduce their temperature and moisture content, enhancing their stability and shelf life. |

Control System | A sophisticated control system oversees the entire process, ensuring precise regulation of parameters like temperature, moisture, and feed rates, for optimal pellet quality and machine efficiency. |

Benefits of High-Efficiency Fully Automated Animal Pellet Feed Machines

The adoption of high-efficiency fully automated animal pellet feed machines brings numerous benefits to farmers and the agricultural industry as a whole:

Increased Efficiency | Automation reduces manual labor and minimizes downtime, leading to higher production rates. |

Consistency in Quality | The precision of the machine ensures that every pellet meets the required standards for nutrient content and physical properties. |

Cost Savings | Efficient use of raw materials and reduced waste translate into cost savings for farmers. |

Healthier Animals | Nutrient-dense pellets promote better health and growth in livestock. |

Benefits of High-Efficiency Fully Automated Animal Pellet Feed Machines

In the ever-evolving landscape of modern farming, the integration of high-efficiency fully automated animal pellet feed machines has emerged as a game-changer, revolutionizing the way livestock nutrition is managed. These advanced machines not only streamline farm operations but also significantly enhance animal health, productivity, and overall farm profitability. Here are some compelling benefits that underscore the importance of adopting such technology:

1. Enhanced Nutrient Consistency and Digestibility

High-efficiency fully automated animal pellet feed machines ensure consistent quality and uniform particle size of feed pellets. This consistency is crucial as it promotes better digestion and nutrient absorption in animals, leading to improved health and growth rates. By precisely controlling the mixing, extrusion, and pelletizing processes, these machines minimize nutrient loss and maximize the bioavailability of essential nutrients.

2. Reduced Waste and Cost Savings

Automation eliminates manual errors and inconsistencies, resulting in less feed waste. Traditional feeding methods often involve overfeeding or underfeeding, leading to uneaten feed that attracts pests and contributes to environmental pollution. With fully automated systems, feed is dispensed accurately according to each animal's needs, reducing waste and associated costs. Additionally, the machines optimize ingredient usage, further contributing to cost savings.

3. Improved Labor Efficiency and Safety

Manual feed preparation and distribution can be labor-intensive, time-consuming, and potentially hazardous for farm workers. High-efficiency fully automated animal pellet feed machines automate these tasks, freeing up labor for other essential farm activities. Automation also minimizes the need for workers to enter potentially dangerous areas, such as livestock pens, enhancing workplace safety.

4. Enhanced Disease Control

Automated feed systems reduce the risk of disease transmission by minimizing human-animal contact during feeding. This is particularly important in large-scale farming operations where even minor health issues can quickly spread. By maintaining a clean and controlled feeding environment, these machines help maintain the overall health and well-being of the herd.

5. Increased Production Efficiency and Profitability

The consistent delivery of high-quality feed pellets supports optimal growth rates and productivity in livestock. This translates into increased milk yield, faster weight gain, and improved reproductive performance, ultimately boosting farm profitability. Furthermore, the efficiency gains from automation allow farmers to manage larger herds with fewer resources, further enhancing their economic viability.

6. Flexibility and Customization

High-efficiency fully automated animal pellet feed machines offer unparalleled flexibility in terms of ingredient formulation and pellet size. Farmers can easily adjust the machine settings to create customized feed formulations tailored to the specific needs of their animals, be it for growth, lactation, or maintenance. This level of customization ensures that each animal receives the optimal nutrition for its stage of life.

Key Features of High-Efficiency Fully Automated Animal Pellet Feed Machines

In the pursuit of optimized farm operations and maximum efficiency, high-efficiency fully automated animal pellet feed machines have emerged as a pivotal component of modern agriculture. These advanced machines boast an array of sophisticated features that revolutionize the way livestock feed is produced and delivered. Here are some of the key features that set these machines apart:

1. Precision Ingredient Control

At the heart of every high-efficiency fully automated animal pellet feed machine lies its precision ingredient control system. This feature ensures that each ingredient is measured and mixed with unwavering accuracy, guaranteeing the consistent quality of the final feed pellets. The system uses advanced sensors and metering devices to monitor and adjust ingredient flow rates in real-time, eliminating the possibility of human error and ensuring optimal nutritional ratios.

2. Advanced Pelletizing Technology

One of the defining features of these machines is their advanced pelletizing technology. By applying intense pressure and heat to the mixed ingredients, the pelletizer forms them into uniform, dense pellets that are easy for animals to consume and digest. The pelletizing process also improves the stability of the feed, reducing moisture absorption and minimizing nutrient loss during storage and transportation.

3. Fully Automated Feed Preparation and Dispensing

High-efficiency fully automated animal pellet feed machines eliminate the need for manual intervention throughout the feed preparation and dispensing process. From ingredient weighing and mixing to pelletizing and delivery, these machines operate seamlessly, ensuring continuous and reliable feed supply to livestock. This automation not only saves time and labor but also minimizes the risk of contamination and cross-contamination between batches.

4. Intuitive Control System

To facilitate ease of operation and monitoring, these machines are equipped with intuitive control systems. These systems typically feature touch screen interfaces, allowing operators to adjust machine settings, monitor process parameters, and receive real-time feedback on the feed production process. Some advanced models even incorporate remote monitoring and control capabilities, enabling farmers to manage their feed machines from anywhere with an internet connection.

5. Durability and Low Maintenance

Built to withstand the demands of continuous operation in harsh farming environments, high-efficiency fully automated animal pellet feed machines are designed for durability and longevity. The machines are constructed from high-quality materials and equipped with robust motors and drivetrains that can withstand heavy workloads. Additionally, these machines are designed for low maintenance, featuring easy-access components and minimal downtime for routine service and repairs.

6. Energy Efficiency and Environmental Compliance

In today's eco-conscious world, energy efficiency and environmental compliance are crucial considerations in the design of high-efficiency fully automated animal pellet feed machines. These machines are engineered to minimize energy consumption and emissions, reducing the carbon footprint of livestock production. Many models incorporate energy-saving features such as variable speed drives and optimized heating elements, while others are designed to comply with international environmental standards and regulations.

In summary, high-efficiency fully automated animal pellet feed machines offer a combination of precision, automation, durability, and energy efficiency that sets them apart in the world of livestock feed production. Their key features, including precision ingredient control, advanced pelletizing technology, fully automated feed preparation and dispensing, intuitive control systems, durability and low maintenance, and energy efficiency, make them indispensable tools for streamlining farm operations and maximizing productivity.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/