The Ultimate Guide to Factory Certification Panko Breadcrumb Machine Bread Dough Rounder in 2024

Introduction

In the evolving landscape of industrial food machinery, ensuring the efficiency and quality of production lines is paramount. This guide focuses on two critical components in the bread-making industry: the Panko Breadcrumb Machine and the Bread Dough Rounder. With the rising demand for precision and quality, factory certification plays a vital role in maintaining standards and enhancing trust. This article will delve into the intricacies of these machines, their importance in the food processing industry, and the necessity of factory certification.

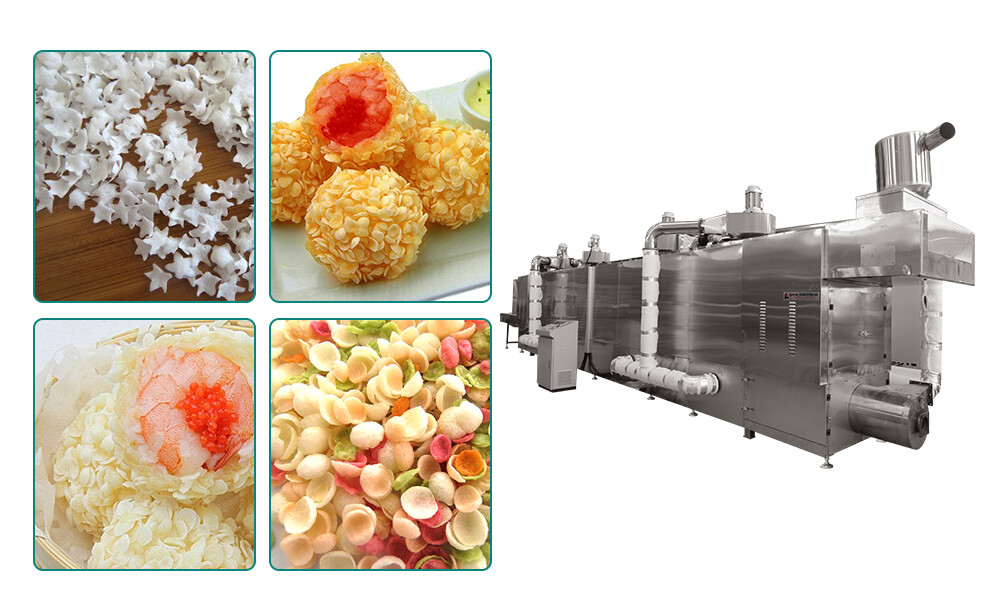

The Panko Breadcrumb Machine is an essential piece of equipment for producing the light, crispy breadcrumbs that are a staple in many culinary applications. These machines are designed to handle large volumes of bread, processing it into uniform, high-quality breadcrumbs. The efficiency and reliability of these machines directly impact the productivity and quality of the end product.

Similarly, the Bread Dough Rounder is crucial in shaping and preparing dough for further processing. This machine ensures that dough pieces are uniformly rounded, promoting consistency in the final baked products. The precision of the bread dough rounder not only affects the appearance but also the texture and quality of the bread.

Factory certification for these machines is indispensable. It ensures that the equipment meets stringent quality and safety standards, providing assurance to manufacturers and consumers alike. Certified machines are subject to rigorous testing and compliance checks, guaranteeing optimal performance and reliability.

Benefits of Factory Certification for Manufacturers and Consumers

Benefit | Description |

| Quality Assurance | Ensures machines meet industry standards, producing consistent, high-quality products. |

| Safety Compliance | Certifies machines adhere to safety protocols, minimizing operational risks and hazards. |

| Operational Efficiency | Optimizes production processes, reducing downtime and enhancing overall efficiency. |

| Consumer Confidence | Builds trust by guaranteeing products meet regulatory requirements and quality expectations. |

| Market Competitiveness | Provides a competitive edge with certified machinery recognized for reliability and performance. |

| Long-Term Investment | Increases machine longevity and durability, minimizing maintenance costs and downtime. |

| Regulatory Compliance | Ensures adherence to local and international regulations, preventing legal complications. |

| Environmental Sustainability | Promotes energy efficiency and waste reduction, aligning with sustainable manufacturing practices. |

Key Features and Advancements of Panko Breadcrumb Machine

Feature | Description |

| High Capacity | Capable of processing large volumes of bread, ensuring efficient production of breadcrumbs. |

| Versatility | Adjustable settings for different breadcrumb textures, from fine to coarse, meeting diverse culinary needs. |

| Automated Operation | Automated feeding, processing, and collection systems streamline workflow and reduce manual labor. |

| Precision Cutting Mechanism | Ensures uniform size and shape of breadcrumbs, enhancing product consistency and quality. |

| Easy Maintenance | Designed for easy cleaning and maintenance, minimizing downtime and operational disruptions. |

| Safety Features | Incorporates safety sensors and guards to protect operators and prevent accidents during operation. |

| Energy Efficiency | Utilizes energy-efficient technologies to reduce operational costs and environmental impact. |

| Digital Controls | Advanced digital interfaces for precise control and monitoring of production parameters. |

Bread Dough Rounder

The bread dough rounder is a crucial component in the production line of bakeries and food manufacturing facilities. Its primary function is to shape portions of dough into uniform rounds, ensuring consistency in size and quality of baked goods. This machine is particularly valued for its efficiency in handling large volumes of dough, streamlining the baking process.

In operation, the bread dough rounder receives portions of dough from the mixer or divider. These portions are fed into the machine, where they undergo a gentle shaping process. The rounder employs rollers and gentle pressure to shape the dough pieces into smooth, evenly rounded balls. This precision is essential for ensuring that each baked product, whether it's bread rolls, buns, or other dough-based items, meets uniform standards in appearance and texture.

Manufacturers often integrate advanced features into bread dough rounders to enhance performance and versatility. These may include adjustable settings for dough weight and rounding speed, as well as mechanisms for easy cleaning and maintenance. Modern models also prioritize hygiene and sanitation, crucial for compliance with food safety regulations.

For bakeries and industrial food production facilities seeking to achieve optimal efficiency and consistency in their baked goods, investing in a high-quality bread dough rounder is essential. These machines not only save time but also contribute significantly to product quality and customer satisfaction by ensuring that each batch of dough is perfectly rounded and ready for baking.

Benefits of Using Certified Machines

Using factory-certified machines such as the Panko Breadcrumb Machine and Bread Dough Rounder offers significant advantages in 2024. These certifications ensure that each machine meets stringent quality standards, guaranteeing reliability and efficiency in food production processes.

Factory Certification:

Factory certification is crucial in the food industry as it verifies that a machine complies with safety, hygiene, and performance standards set by regulatory bodies. This certification assures manufacturers and consumers alike of the machine's reliability and suitability for commercial food production environments.

Panko Breadcrumb Machine:

A certified Panko Breadcrumb Machine ensures consistent and uniform breadcrumb production, crucial for enhancing the texture and flavor of fried foods. It meets industry standards for processing efficiency and hygiene, minimizing downtime and ensuring product quality.

Bread Dough Rounder:

Certified Bread Dough Rounders streamline the process of shaping dough, maintaining uniformity in size and texture of bread products. These machines are designed to handle high volumes of dough while adhering to food safety regulations, enhancing productivity in bakery operations.

Innovations in Panko Breadcrumb Bachines and Bread Dough Rounders

Innovations in Panko breadcrumb machines and bread dough rounders have revolutionized the food processing industry, setting new standards in efficiency and quality. Factory certification plays a crucial role in ensuring these machines meet rigorous standards for safety, hygiene, and production reliability.

Factory Certification

Factory certification for industrial food machinery such as Panko breadcrumb machines and bread dough rounders involves comprehensive assessments of manufacturing processes, equipment performance, and compliance with international standards. Certification bodies evaluate factors like equipment design, materials used, and adherence to food safety regulations.

Panko Breadcrumb Machine

Modern Panko breadcrumb machines integrate advanced technologies to achieve precise cutting and coating of bread crumbs. These machines are equipped with automated systems that regulate the consistency and texture of breadcrumbs, ensuring uniform quality batch after batch. Key features include adjustable settings for crumb size and coating thickness, catering to diverse culinary applications from crispy coatings to breading mixes.

Bread Dough Rounder

The evolution of bread dough rounders has streamlined the production of dough balls, enhancing efficiency in bakeries and food processing facilities. These machines utilize gentle handling techniques to maintain dough integrity while shaping it into perfectly rounded portions. Advanced models offer customizable settings for dough weight and rounding intensity, accommodating various dough types from soft breads to artisanal loaves.As demand grows for high-quality bread products and crispy coatings, the role of factory-certified Panko breadcrumb machines and bread dough rounders becomes increasingly pivotal. These innovations not only elevate production standards but also ensure consistency and reliability in food manufacturing processes. Stay ahead in 2024 with certified machinery that meets the stringent requirements of modern food industries.

The Role of Automation and AI in the Future of Food Machinery

The food machinery industry is rapidly transforming with the integration of automation and AI technologies. In 2024, these advancements play a crucial role in enhancing the efficiency, precision, and compliance of machines like the Panko breadcrumb machine and the bread dough rounder.

Automation in Panko Breadcrumb Machines

Modern Panko breadcrumb machines are equipped with sophisticated automation systems that streamline the production process. These machines can now operate with minimal human intervention, ensuring consistent quality and texture in every batch of breadcrumbs. Automation also facilitates compliance with factory certification standards by maintaining strict control over production parameters, reducing human error, and increasing operational efficiency. Additionally, automated systems enable real-time monitoring and diagnostics, significantly minimizing downtime and maintenance costs.

AI in Bread Dough Rounders

AI technology is revolutionizing bread dough rounders by enabling adaptive and intelligent processing. AI algorithms analyze various factors such as dough consistency, temperature, and humidity to adjust the rounding process dynamically. This results in perfectly rounded dough pieces every time, irrespective of variations in the dough properties. The integration of AI ensures that the machines meet rigorous factory certification standards by consistently producing high-quality products that adhere to safety and hygiene regulations. Moreover, AI-powered rounders can predict maintenance needs and optimize energy consumption, further enhancing their efficiency and reliability.

Factory Certification

Achieving factory certification is essential for food machinery manufacturers to ensure their products meet industry standards for quality and safety. The integration of automation and AI in Panko breadcrumb machines and bread dough rounders plays a vital role in achieving and maintaining these certifications. Automated systems ensure that production processes are repeatable and verifiable, which is a key requirement for certification. AI technologies, on the other hand, enhance traceability and compliance by providing detailed records of production data and predictive analytics.The incorporation of automation and AI in Panko breadcrumb machines and bread dough rounders marks a significant leap forward in the food machinery industry. These technologies not only enhance the efficiency and precision of these machines but also ensure they comply with stringent factory certification standards. As we move further into 2024, the role of automation and AI in food machinery will continue to expand, driving innovations that will shape the future of food production.

Maintenance and Troubleshooting

Effective maintenance and troubleshooting are crucial for ensuring the optimal performance and longevity of food machinery, particularly Panko breadcrumb machines and bread dough rounders. Proper upkeep not only enhances efficiency but also ensures compliance with factory certification standards, which are essential for maintaining quality and safety in food production.

Maintenance of Panko Breadcrumb Machines

Regular Cleaning and Lubrication: To maintain the functionality of a Panko breadcrumb machine, it is essential to regularly clean and lubricate its components. This prevents the build-up of crumbs and other residues that could lead to mechanical failures or contamination. Using food-grade lubricants ensures that the machine operates smoothly without risking product contamination.

Inspection and Replacement of Worn Parts: Routine inspections are vital to identify any worn or damaged parts in the Panko breadcrumb machine. Replacing these components promptly can prevent breakdowns and extend the machine's lifespan. Key parts to monitor include the cutting blades, conveyors, and motors.

Calibration and Adjustment: Regular calibration of the machine ensures that it produces breadcrumbs of consistent size and texture. Adjusting settings based on production requirements helps maintain product quality and complies with factory certification standards, which often mandate stringent quality control measures.

Troubleshooting Panko Breadcrumb Machines

Identifying Common Issues: Common issues with Panko breadcrumb machines include irregular breadcrumb size, machine jamming, and unexpected shutdowns. Diagnosing the root cause, whether it is a mechanical fault, software glitch, or power supply issue, is the first step in troubleshooting.

Resolving Mechanical Failures: For mechanical problems, such as broken blades or conveyor issues, replacing the faulty components is essential. Ensuring that spare parts are readily available can minimize downtime during repairs.

Addressing Software and Electrical Issues: Modern Panko breadcrumb machines often incorporate advanced software and electrical systems. Troubleshooting software-related problems may involve updating the firmware or resetting the system. For electrical issues, checking connections and ensuring stable power supply is crucial.

Maintenance of Bread Dough Rounders

Regular Cleaning and Sanitization: Bread dough rounders must be cleaned and sanitized regularly to prevent dough residue build-up, which can lead to bacterial growth and machine malfunctions. Using appropriate cleaning agents and following a strict cleaning schedule is necessary to meet factory certification standards.

Lubrication and Part Replacement: Lubricating moving parts, such as rollers and belts, ensures smooth operation and reduces wear and tear. Regularly inspecting and replacing worn components, such as rounding belts and motor parts, helps maintain the rounder’s efficiency and reliability.

Calibration and Settings Adjustment: Adjusting the settings of the bread dough rounder based on dough type and production requirements ensures uniform shaping and consistent quality. Regular calibration is vital to meet production standards and comply with factory certification requirements.

Troubleshooting Bread Dough Rounders

Diagnosing Common Problems: Issues such as uneven dough rounding, machine jamming, and operational delays are common in bread dough rounders. Identifying whether these problems stem from mechanical, electrical, or software sources is crucial for effective troubleshooting.

Mechanical Repairs: Replacing worn or broken parts, such as rollers and belts, is a common solution for mechanical issues. Ensuring that the machine is properly assembled and all parts are in good condition can prevent many operational problems.

Software and Electrical Fixes: For modern bread dough rounders with integrated software systems, troubleshooting may involve updating software, recalibrating settings, or checking for electrical faults. Ensuring stable power supply and secure connections can resolve many electrical issues.

Maintaining and troubleshooting Panko breadcrumb machines and bread dough rounders are essential for optimal performance and compliance with factory certification standards. Regular maintenance, including cleaning, lubrication, inspection, and calibration, along with effective troubleshooting of common issues, ensures these machines operate efficiently and reliably in food production environments.

References

The following are five authoritative foreign literature websites in the field of industrial bread crumb maker:

1.SpringerLink

Website: [https://link.springer.com]

2.Himax Machinery

Website: [https://www.himaxmachinery.com]

3.Brook Food

Website: [https://www.brookfood.co.uk]

4.IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

5.ScienceDirect

Website: [https://www.sciencedirect.com/]