The Ultimate Guide To Corn Puff Snacks Manufacturing Line Updated 2025

Introduction

Welcome to the ultimate guide to the Corn Puff Snacks Manufacturing Line, updated for 2024. As an industrial food machinery expert, I understand the intricacies involved in the production of high-quality corn puff snacks. In this guide, we will delve into the nuts and bolts of the Corn Puff Snacks Manufacturing Line, providing insights into its components, processes, and advancements.

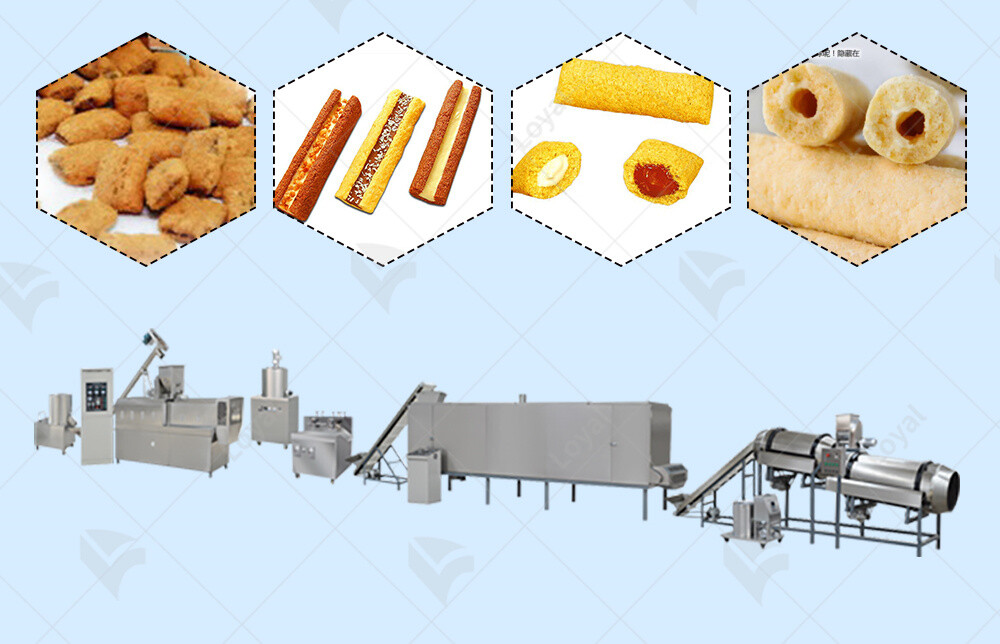

The Corn Puff Snacks Manufacturing Line is a sophisticated system designed to efficiently produce delicious and crunchy corn puff snacks. These snacks have gained immense popularity due to their unique texture and flavor, making them a staple in many households and snack bars worldwide.

In this guide, we will explore the latest technologies and innovations driving the Corn Puff Snacks Manufacturing Line in 2024. From the initial stages of corn grinding and mixing to the final packaging of the snacks, each step of the process is crucial in ensuring the quality and consistency of the final product.

As food machinery continues to evolve, so does the Corn Puff Snacks Manufacturing Line. Manufacturers are constantly striving to improve efficiency, reduce costs, and enhance the overall quality of the snacks produced. In this guide, we will discuss the various components and technologies that make up a modern Corn Puff Snacks Manufacturing Line, as well as the regulations and safety standards that must be adhered to throughout the production process.

Whether you are a seasoned professional in the food machinery industry or a newcomer looking to venture into the world of corn puff snacks manufacturing, this guide will provide you with the knowledge and insights you need to succeed. So, let's get started and uncover the secrets of the Corn Puff Snacks Manufacturing Line in 2024.

Overview of the Corn Puff Snacks Manufacturing Process

The Corn Puff Snacks Manufacturing Line is a sophisticated system designed to efficiently produce delicious and crunchy corn puff snacks. As an industrial food machinery expert, I will provide an overview of the manufacturing process, highlighting the key steps and equipment involved. Understanding this process is crucial for anyone looking to invest in or operate such a line, ensuring optimal efficiency and product quality.

Initial Preparation

The journey of creating corn puff snacks begins with the careful selection and preparation of raw materials. High-quality corn flour serves as the primary ingredient, which is blended with water and other necessary additives to achieve the desired dough consistency. This blend is then subjected to a conditioning process to ensure uniform moisture distribution and enhance dough pliability.

Extrusion and Puffing

Next, the conditioned dough is fed into an extruder, a critical piece of equipment in the Corn Puff Snacks Manufacturing Line. The extruder applies intense pressure and heat to the dough, forcing it through a die with tiny holes. As the dough exits the die, the sudden drop in pressure causes it to expand rapidly, creating the characteristic puffed shape of corn puff snacks.

Frying and Cooling

Immediately after extrusion, the puffed snacks are conveyed into a fryer where they are immersed in hot oil. The frying process not only gives the snacks their golden-brown appearance but also imparts a crispy texture and delicious flavor. After frying, the snacks are quickly moved to a cooling conveyor to prevent overcooking and ensure they maintain their shape and texture.

Seasoning and Packaging

Once cooled, the corn puff snacks are ready for seasoning. This step involves applying a blend of oils, spices, and flavorings to enhance their taste and appeal. Automated seasoning equipment ensures consistent and even application of seasoning across all snacks. Following seasoning, the snacks are packaged using high-speed packaging machinery that seals them in airtight containers, preserving freshness and extending shelf life.

Quality Control and Inspection

Throughout the manufacturing process, quality control measures are in place to ensure that each batch of corn puff snacks meets strict standards for safety, quality, and consistency. Advanced inspection technologies, such as metal detectors and x-ray machines, are used to detect any contaminants or defects in the final product.

Key Components & Technology of a Modern Corn Puff Snacks Manufacturing Line

In the realm of industrial food machinery, the Corn Puff Snacks Manufacturing Line is a sophisticated system designed to efficiently produce high-quality corn puff snacks. As an expert in the field, I have compiled a detailed guide outlining the key components and technologies that form the backbone of a modern corn puff snacks manufacturing line. Below is a concise, structured representation of these components in a table format:

Component/Technology | Description | Significance |

Corn Grinding Equipment | High-speed grinders equipped with precision blades for milling corn kernels into fine flour. | Essential for achieving a uniform particle size, which is critical for consistent extrusion and puffing. |

Mixing System | Automated mixers that blend the corn flour with other ingredients like water, salt, and seasonings. | Ensures homogeneous mixing, enhancing the overall taste and texture of the final product. |

Extrusion Machinery | Advanced extruders with adjustable temperatures and pressures to shape the dough into desired puff shapes. | The heart of the manufacturing line, where the dough is cooked and expanded into puffs. |

Frying & Drying Systems | Continuous frying belts and drying ovens to cook and crisp the puffs while removing excess moisture. | Crucial for achieving the desired crunchiness and texture of corn puff snacks. |

Flavoring & Seasoning Applications | Automated spray systems for evenly applying flavorings, seasonings, and coatings to the puffs. | Enhances the appeal and taste profile of the snacks, catering to diverse consumer preferences. |

Packaging Machinery | High-speed packaging lines with automated sealing and labeling capabilities. | Protects the snacks from moisture and contamination, ensuring extended shelf life and consumer satisfaction. |

Automation & Control Systems | PLC (Programmable Logic Controllers) and SCADA (Supervisory Control And Data Acquisition) systems for monitoring and controlling the entire manufacturing process. | Provides real-time data and alerts, enabling predictive maintenance and optimizing production efficiency. |

Quality Control Equipment | Metal detectors, X-ray machines, and vision inspection systems to detect contaminants and ensure product integrity. | Ensures compliance with food safety regulations and consumer trust. |

Advances & Innovations in Corn Puff Snacks Manufacturing Line 2024

As an industrial food machinery expert, I am constantly amazed by the rapid advancements and innovations in the corn puff snacks manufacturing line. In 2024, the industry has witnessed several groundbreaking developments that have significantly enhanced the efficiency, quality, and sustainability of corn puff snacks production.

One of the most notable advancements is the integration of automation and robotics in the manufacturing process. Automated conveyors, robotic arms, and intelligent sensors have replaced manual labor in various stages of production, from mixing and extrusion to packaging and inspection. This not only reduces human error but also increases production speed and consistency, ensuring that every batch of corn puff snacks meets the highest quality standards.

Moreover, the introduction of advanced extrusion technology has revolutionized the shaping and texturing of corn puff snacks. High-precision extruders with adjustable settings for temperature, pressure, and die configuration allow manufacturers to create a wide range of shapes, sizes, and textures, catering to the diverse preferences of consumers. This flexibility is crucial in today's competitive market, where innovation and customization are key drivers of growth.

In terms of sustainability, the corn puff snacks manufacturing line has also made significant strides. Manufacturers are increasingly adopting energy-efficient machinery and sustainable packaging materials to reduce their carbon footprint. Additionally, advancements in waste management and recycling technologies have enabled the industry to minimize waste and maximize resource utilization.

Another exciting innovation in the corn puff snacks manufacturing line is the integration of artificial intelligence (AI) and machine learning algorithms. These technologies are being used to optimize production processes, predict maintenance needs, and monitor product quality in real-time. By analyzing vast amounts of data collected from sensors and machines, AI-powered systems can identify inefficiencies, predict potential failures, and recommend improvements, leading to significant cost savings and increased productivity.

Regulations & Safety Standards for Corn Puff Snacks Production

In the food industry, especially when dealing with snack manufacturing like Corn Puff Snacks, adhering to regulations and safety standards is paramount. As an industrial food machinery expert, I often emphasize the critical role these guidelines play in ensuring the quality, safety, and legality of food products. When it comes to the Corn Puff Snacks Manufacturing Line, there are several key regulations and safety standards that must be followed to maintain compliance and consumer trust.

Firstly, all food manufacturing facilities, including those producing Corn Puff Snacks, must comply with the Good Manufacturing Practices (GMP) outlined by various food regulatory bodies globally. GMPs cover a wide range of areas, from cleanliness and sanitation to employee training and product handling. Adhering to GMPs ensures that food is produced in a controlled environment, minimizing the risk of contamination and ensuring product safety.

Secondly, food safety standards such as Hazard Analysis and Critical Control Points (HACCP) are essential for identifying, evaluating, and controlling hazards in the Corn Puff Snacks Manufacturing Line. HACCP involves a systematic approach to food safety that focuses on preventing hazards rather than relying on end-product testing. By implementing HACCP, manufacturers can identify potential food safety hazards and establish control measures to eliminate or reduce these risks.

In addition to GMPs and HACCP, there are specific regulations related to food additives, labeling, and packaging that must be adhered to when producing Corn Puff Snacks. These regulations vary by country and region, but typically include restrictions on the use of certain additives, requirements for accurate labeling of ingredients and nutritional information, and standards for packaging materials and storage conditions.

Moreover, environmental regulations also play a significant role in the Corn Puff Snacks Manufacturing Line. Manufacturers must ensure that their production processes are environmentally friendly, minimizing waste and emissions while maximizing energy efficiency. This not only helps in complying with environmental regulations but also contributes to sustainable food production practices.

Lastly, regular audits and inspections by food safety authorities are crucial for maintaining compliance with regulations and safety standards. These audits help identify any gaps in the manufacturing process and provide an opportunity for corrective actions to be taken. Manufacturers should actively seek out these audits and work with food safety authorities to continuously improve their production practices.

In conclusion, adhering to regulations and safety standards is essential for ensuring the quality, safety, and legality of Corn Puff Snacks produced on a manufacturing line. By implementing GMPs, HACCP, adhering to food additive and labeling regulations, considering environmental regulations, and undergoing regular audits and inspections, manufacturers can maintain compliance and build consumer trust in their products.

Maintenance & Troubleshooting Tips for Corn Puff Snacks Manufacturing Line

Maintaining a Corn Puff Snacks Manufacturing Line is crucial for ensuring optimal production, quality, and safety. As an industrial food machinery expert, I have compiled a list of maintenance and troubleshooting tips that will help you keep your manufacturing line running smoothly.

Maintenance Tips:

Regular Inspections: Conduct routine inspections of all machinery components. Look for signs of wear and tear, such as cracked belts, worn gears, or loose bolts. Address any issues promptly to prevent downtime and potential accidents.

Lubrication: Regularly lubricate moving parts to reduce friction and wear. Follow the manufacturer's recommendations for the type and frequency of lubrication.

Cleaning: Keep the manufacturing line clean to prevent contamination and build-up of residue. Use food-safe cleaning agents and follow proper cleaning procedures to ensure sanitation.

Temperature Control: Monitor and maintain the optimal temperature settings for frying and drying processes. Fluctuations in temperature can affect the quality and texture of the corn puff snacks.

Sensor Calibration: Regularly calibrate sensors used for monitoring temperature, humidity, and other critical parameters. Accurate sensor readings are essential for maintaining product quality.

Troubleshooting Tips:

Production Slowdown: If you notice a sudden slowdown in production, check for obstructions in the conveyor belts or extruder. Clear any jams and adjust the machinery settings as needed.

Uneven Puff Size: Uneven puff size can be caused by inconsistent ingredient mixing or extruder settings. Ensure that all ingredients are properly mixed and adjust the extruder die size for uniform puff shape and size.

Overcooking/Undercooking: Monitor the frying and drying times closely. Adjust the timers and temperature settings as necessary to achieve the desired texture and color of the corn puff snacks.

Excessive Noise: Excessive noise can indicate wear and tear on machinery components. Identify the source of the noise and replace or repair the affected parts promptly.

Automated System Failures: If your manufacturing line includes automated systems for packaging or quality control, ensure that the software is up-to-date and that all sensors and actuators are functioning correctly. Regular backups of system data can also help in troubleshooting and recovery in case of software failures.

Conclusion

In conclusion, the Corn Puff Snacks Manufacturing Line is a sophisticated and efficient system that combines advanced technology with precision engineering to produce high-quality corn puff snacks. As an industrial food machinery expert, I have provided a comprehensive guide covering everything from raw material selection and formulation to the latest trends in automation and technology integration. By understanding the key components, process flow, automation options, quality control measures, regulatory compliance, economic considerations, energy efficiency, and maintenance tips, you can optimize your manufacturing line for maximum productivity and profitability. As we approach 2025, staying updated with the latest advancements in Corn Puff Snacks Manufacturing Line technology will be crucial for maintaining a competitive edge in the market.

Reference

Here are five authoritative foreign websites related to industrial food machinery, along with their URLs:

1.ThomasNet

Website: https://www.thomasnet.com

2.MachineryTrader

Website: https://www.machinerytrader.com

3.Food Engineering:https://www.foodengineeringmag.com

4.Pack Expo:https://www.packexpo.com

5.DirectIndustry:https://www.directindustry.com