The Ultimate Guide to Breakfast Cereal Machine in 2024

Introduction

In the fast-paced world of food production, Breakfast Cereal Machines have become indispensable tools for manufacturers aiming to meet the growing demand for breakfast cereals. As we move through 2024, understanding the importance and innovations of these machines is crucial for any industry professional. This guide will provide a comprehensive overview of the current state of breakfast cereal production, highlighting the key trends and technologies shaping the future.

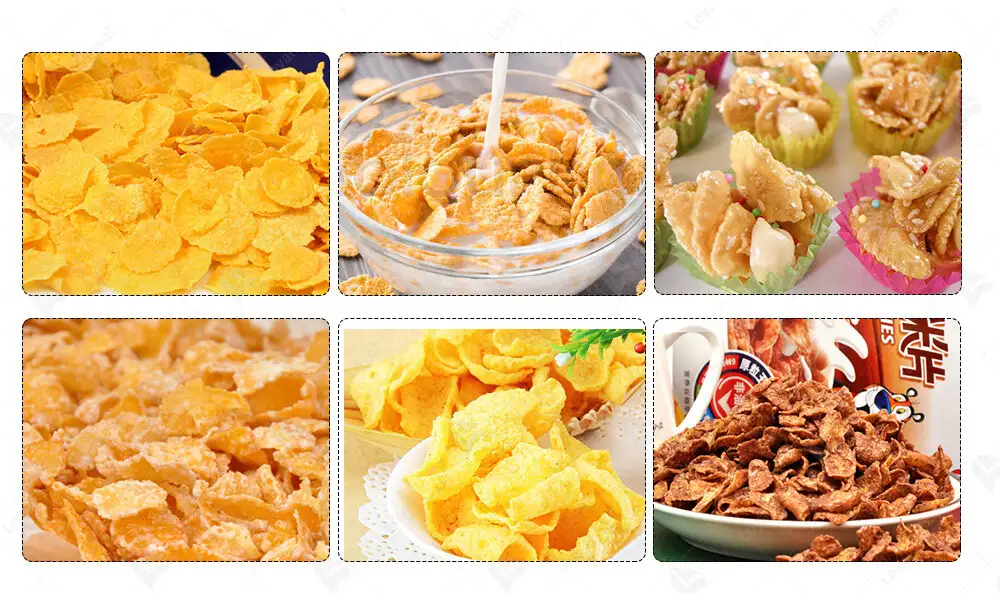

Breakfast Cereal Machines are specialized industrial equipment designed to produce a variety of breakfast cereals, including flakes, puffs, and coated cereals. These machines are pivotal in ensuring consistent quality, high efficiency, and scalable production. With the increasing popularity of healthy and convenient breakfast options, the demand for advanced cereal production equipment has never been higher.

The breakfast cereal production process involves several stages, each requiring specific machinery to achieve the desired product. From mixing and blending ingredients to shaping, cooking, and coating, each step is meticulously controlled to maintain product standards and meet consumer preferences. In 2024, the focus is not only on productivity but also on sustainability and innovation, driving the industry towards more eco-friendly and technologically advanced solutions.

Key trends in Breakfast Cereal Machines include automation, which enhances efficiency and reduces labor costs; integration of IoT for real-time monitoring and control; and the development of energy-efficient technologies to reduce environmental impact. These trends are transforming the industry, making it essential for manufacturers to stay updated with the latest advancements to remain competitive.

By exploring the various types of breakfast cereal machines, their components, and the latest innovations, this guide aims to equip industry professionals with the knowledge needed to optimize their production lines and adapt to the evolving market demands. Whether you are considering investing in new equipment or upgrading your existing machinery, understanding these aspects will help you make informed decisions and achieve operational excellence.

Types of Breakfast Cereal Machines

When it comes to producing high-quality breakfast cereals, selecting the right Breakfast Cereal Machine is crucial. Different types of machines cater to various stages of cereal production, each designed to achieve specific textures, shapes, and flavors. Here, we explore the primary types of breakfast cereal machines used in the industry.

1. Flaking Machines

Flaking machines are essential for creating cereal flakes, such as cornflakes and bran flakes. These machines work by pressing cooked grains between large rollers, flattening them into thin, crispy flakes. The precision of the rollers ensures uniform thickness, which is vital for consistent cooking and quality.

2. Puffing Machines

Puffing machines are used to produce puffed cereals like rice puffs and puffed wheat. These machines utilize high-pressure steam to cook the grains, which then expand rapidly when the pressure is released. The result is a light, airy texture that is a hallmark of many popular breakfast cereals.

3. Coating Machines

Coating machines are designed to add flavors, sugars, and vitamins to the cereal. They apply a uniform layer of coating to each piece, ensuring that the final product is both tasty and nutritious. These machines are often used in conjunction with drying ovens to set the coating properly.

4. Mixing and Blending Machines

Mixing and blending machines are crucial at the initial stage of cereal production. These machines combine various ingredients such as grains, sweeteners, and flavorings into a homogenous mixture. The consistency of this mixture is key to the quality and taste of the final product.

Key Components and Functions

Component | Function |

| Mixing Chamber | Combines various ingredients such as grains, sweeteners, and flavorings into a homogenous mixture. Ensures even distribution and consistency. |

| Extruder | Shapes and cooks the cereal dough through high pressure and temperature, producing various shapes and textures. It is critical for forming the base of cereals like puffs and flakes. |

| Drying Oven | Removes moisture from the cereal to achieve the desired crunchiness and prolong shelf life. Consistent drying is key to maintaining product quality. |

| Coating Drum | Applies a uniform layer of flavors, sugars, and vitamins to the cereal. The coating drum ensures that each piece is evenly coated for taste and nutritional consistency. |

| Cooling Conveyor | Cools down the cereal after it exits the drying oven or coating drum. Rapid cooling helps set the shape and coating of the cereal. |

| Roller Mills | Used primarily in flaking machines, these rollers press the cooked grains into thin, uniform flakes. Precision rollers are essential for consistent flake thickness. |

| Steam Injector | Utilized in puffing machines, it introduces high-pressure steam to cook and expand the grains, creating the light and airy texture characteristic of puffed cereals. |

| Quality Control Sensors | Embedded throughout the production line, these sensors monitor parameters such as temperature, pressure, and moisture content to ensure consistent quality and compliance with safety standards. |

| Packaging Unit | Final stage where cereals are weighed, filled into packages, and sealed. Modern units often include features for automated packaging and labeling. |

Key Features of a Breakfast Cereal Machine

Feature | Description |

| Automated Controls | Advanced automated controls for precise management of the production process, maintaining consistency, reducing human error, and increasing efficiency. |

| High-Capacity Output | Designed for large-scale production, allowing significant quantities of cereal to be produced quickly, crucial for meeting growing market demand. |

| Multi-Functionality | Equipped with multiple functions such as mixing, cooking, shaping, and coating, enabling the production of various cereal types with a single machine. |

| Energy Efficiency | Energy-efficient features that reduce energy consumption and operational costs, contributing to a more sustainable production process. |

| Real-Time Monitoring | IoT capabilities for real-time monitoring of critical parameters like temperature, pressure, and moisture levels, ensuring optimal conditions and enhancing product quality. |

| Customizable Settings | Adjustable machine parameters to meet specific production needs, allowing the creation of different cereal varieties and catering to diverse consumer preferences. |

| Hygienic Design | Prioritizes hygiene with stainless steel construction and easy-access components for easy cleaning, ensuring high sanitation standards and regulatory compliance. |

| Safety Features | Incorporates safety features such as emergency stop buttons, safety guards, and automated shutdown systems to ensure operator safety and smooth operation. |

How Breakfast Cereal Machines Work

Understanding the operational mechanics of a Breakfast Cereal Machine is essential for optimizing production and ensuring high-quality output. This chapter delves into the step-by-step process of how these machines work, highlighting the critical stages involved in cereal production.

Mixing and Blending

The first stage in the operation of a Breakfast Cereal Machine involves mixing and blending various ingredients. Grains, sweeteners, flavorings, and other additives are combined in precise proportions to form a homogenous mixture. Mixing chambers equipped with powerful agitators ensure thorough blending, which is crucial for consistent quality.

Extrusion

Once the ingredients are mixed, the next step is extrusion. The mixture is fed into an extruder, where it is subjected to high pressure and temperature. The extruder shapes the cereal dough into the desired forms, such as flakes, rings, or puffs. The extrusion process not only shapes the cereal but also cooks it, achieving the necessary texture and structure.

Cooking and Drying

After extrusion, the cereal pieces undergo further cooking and drying. Drying ovens remove moisture from the cereal to achieve the desired crunchiness and extend shelf life. Uniform drying is critical to maintaining product consistency and preventing spoilage.

Coating

In this stage, the dried cereal pieces are transferred to a coating drum, where they are coated with flavors, sugars, and vitamins. The coating drum ensures an even application, enhancing the taste and nutritional value of the cereal. This step is particularly important for cereals that require a sweet or fortified coating.

Cooling

Once coated, the cereal needs to be cooled to set the coating and stabilize the product. Cooling conveyors rapidly reduce the temperature of the cereal, preventing clumping and ensuring that each piece retains its shape and texture.

Quality Control

Throughout the production process, quality control sensors monitor critical parameters such as temperature, pressure, and moisture levels. These sensors ensure that the production conditions remain optimal and that the final product meets the required quality standards. Any deviations are immediately corrected to maintain consistency.

Packaging

The final step in the operation of a Breakfast Cereal Machine is packaging. The cereal is weighed, filled into packages, and sealed. Modern packaging units are often equipped with automated systems that ensure precise filling and sealing, maintaining product freshness and quality.

Technological Innovations in 2024

In 2024, Breakfast Cereal Machines are at the forefront of technological advancements, integrating cutting-edge features to enhance efficiency, quality, and sustainability in cereal production. Here are some of the most significant innovations transforming the industry:

1. Advanced Automation

Breakfast Cereal Machines now feature advanced automation systems that streamline the production process. These systems minimize human intervention, reduce errors, and increase production speed. Automated controls enable precise adjustments to temperature, pressure, and timing, ensuring consistent product quality.

2. IoT Integration

The Internet of Things (IoT) has become integral to modern Breakfast Cereal Machines. IoT-enabled devices provide real-time data monitoring and analytics, allowing manufacturers to optimize production parameters continuously. This technology also facilitates predictive maintenance, reducing downtime and extending the lifespan of machinery.

3. Energy-Efficient Technologies

Sustainability is a key focus in 2024, and Breakfast Cereal Machines are incorporating energy-efficient technologies to minimize environmental impact. Innovations such as energy recovery systems and low-energy consumption components help reduce the carbon footprint of cereal production.

4. Enhanced Quality Control

Quality control has been significantly improved with the integration of advanced sensors and imaging technologies. These features enable real-time inspection of cereal products for defects, ensuring that only high-quality cereals reach the market. Automated rejection systems remove defective items from the production line promptly.

5. Flexible Production Capabilities

Modern Breakfast Cereal Machines are designed for flexibility, allowing manufacturers to switch between different cereal types and recipes quickly. Modular components and programmable settings make it easy to adapt to changing consumer demands and trends.

6. Sustainable Materials and Processes

The use of sustainable materials and eco-friendly production processes is gaining traction. Breakfast Cereal Machines now often incorporate recyclable materials and processes that reduce waste and energy consumption, aligning with global sustainability goals.

7. Artificial Intelligence (AI)

AI is playing a crucial role in optimizing cereal production. AI algorithms analyze data from various stages of the production process to identify patterns and recommend improvements. This results in enhanced efficiency, reduced waste, and better overall product quality.

Installation and Setup

Installation and Setup

Proper installation and setup of a Breakfast Cereal Machine are crucial to ensure optimal performance and longevity. This section outlines the key steps and considerations for successfully installing and setting up these complex machines.

Site Preparation

Before installing a Breakfast Cereal Machine, it's essential to prepare the installation site. Ensure that the location has adequate space to accommodate the machine and allows for easy access for maintenance and operation. The site should also have proper ventilation and meet all safety and hygiene standards required for food production.

Unpacking and Inspection

Carefully unpack the Breakfast Cereal Machine and inspect all components for any damage incurred during transit. Check for missing parts and verify that all items match the packing list. Any discrepancies or damages should be reported to the supplier immediately.

Positioning the Machine

Place the Breakfast Cereal Machine in its designated location, ensuring that it is level and stable. Proper alignment is critical to prevent operational issues and ensure smooth functioning. Use leveling tools to adjust the machine's position if necessary.

Electrical and Utility Connections

Connect the machine to the required utilities, including electrical power, water, and compressed air. Ensure that all connections comply with the manufacturer's specifications and local regulations. Use the correct voltage and amperage to avoid electrical issues. Additionally, make sure that water and air supplies are clean and free from contaminants.

Calibration and Configuration

Once the Breakfast Cereal Machine is positioned and connected, perform the initial calibration and configuration. Follow the manufacturer's guidelines to set up the control system, adjust parameters, and test all functions. Calibration is essential to ensure accuracy in mixing, cooking, shaping, and coating processes.

Testing and Trial Runs

Conduct thorough testing and trial runs to verify that the Breakfast Cereal Machine operates correctly. Start with small batches to fine-tune settings and ensure that all components function as expected. Check for any issues such as irregularities in the extrusion process, uneven drying, or coating inconsistencies. Make necessary adjustments based on the trial results.

Training and Documentation

Provide comprehensive training for all operators and maintenance personnel. Ensure that they are familiar with the machine's operation, safety protocols, and maintenance procedures. Keep detailed documentation, including the installation manual, calibration records, and troubleshooting guides, readily available.

Final Inspection and Handover

Perform a final inspection to ensure that the Breakfast Cereal Machine is fully operational and meets all performance standards. Once satisfied, hand over the machine to the production team, ensuring that all stakeholders are informed about the setup and ready to begin production.

Maintenance and Troubleshooting of Breakfast Cereal Machines

Maintaining optimal performance of a Breakfast Cereal Machine is essential to ensure continuous production and high-quality output. This chapter explores the key aspects of maintenance and troubleshooting to keep these machines running smoothly in 2024 and beyond.

Regular Maintenance Schedule

Establishing a regular maintenance schedule is critical for preventing breakdowns and extending the lifespan of your Breakfast Cereal Machine. Schedule routine inspections and servicing of components such as motors, belts, bearings, and seals. Lubricate moving parts as per manufacturer recommendations to minimize wear and friction.

Cleaning and Sanitization

Maintain strict cleanliness standards to prevent contamination and ensure food safety. Regularly clean all surfaces that come into contact with food products, including mixing chambers, extruders, coating drums, and conveyors. Use approved cleaning agents and follow proper sanitation protocols to eliminate bacteria and residue buildup.

Calibration and Adjustment

Periodically calibrate the Breakfast Cereal Machine to ensure accurate performance. Verify settings for temperature, pressure, and speed control to maintain consistency in cereal production. Make necessary adjustments based on production requirements and quality standards.

Inspection of Wear and Tear

Monitor wear and tear on critical components to identify signs of degradation early. Inspect belts for signs of cracking or stretching, check seals and gaskets for leaks, and examine electrical connections for corrosion. Replace worn-out parts promptly to prevent equipment failure during operation.

Troubleshooting Common Issues

Develop troubleshooting protocols to address common issues quickly and effectively. Train operators to identify and resolve problems such as irregular product shapes, inconsistent coating, or machine malfunctions. Document troubleshooting procedures for reference during emergencies.

Preventive Measures

Implement preventive measures to mitigate potential risks and optimize machine performance. Install protective guards and safety features to prevent accidents. Conduct regular safety audits and maintain compliance with industry standards and regulations.

Emergency Preparedness

Prepare for unexpected downtime by maintaining an inventory of spare parts and essential supplies. Develop contingency plans for emergency repairs and establish communication protocols with maintenance teams and suppliers.

Operator Training and Feedback

Provide comprehensive training to operators on machine operation, maintenance procedures, and safety protocols. Encourage operators to report any anomalies or performance issues promptly. Use operator feedback to improve maintenance strategies and enhance machine reliability.

Documentation and Record-Keeping

Maintain detailed records of maintenance activities, including schedules, inspections, repairs, and equipment upgrades. Keep manuals, schematics, and technical documentation readily accessible for troubleshooting and reference.

References

Here are five authoritative literature websites about industrial corn flakes making machines:

1.ScienceDirect

Website: [https://www.sciencedirect.com/]

2.IEEE Xplore

Website: [https://ieeexplore.ieee.org/Xplore/home.jsp]

3.SpringerLink

Website: [https://link.springer.com/]

4.Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5.ResearchGate

Website: [https://www.researchgate.net/]